Material continuous negative pressure centrifugal separation drying device

A centrifugal separation and drying device technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of drying difficulties, lower production efficiency, loss of nutrients, etc., to improve the quality of biological products, reduce production costs, The effect of preserving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

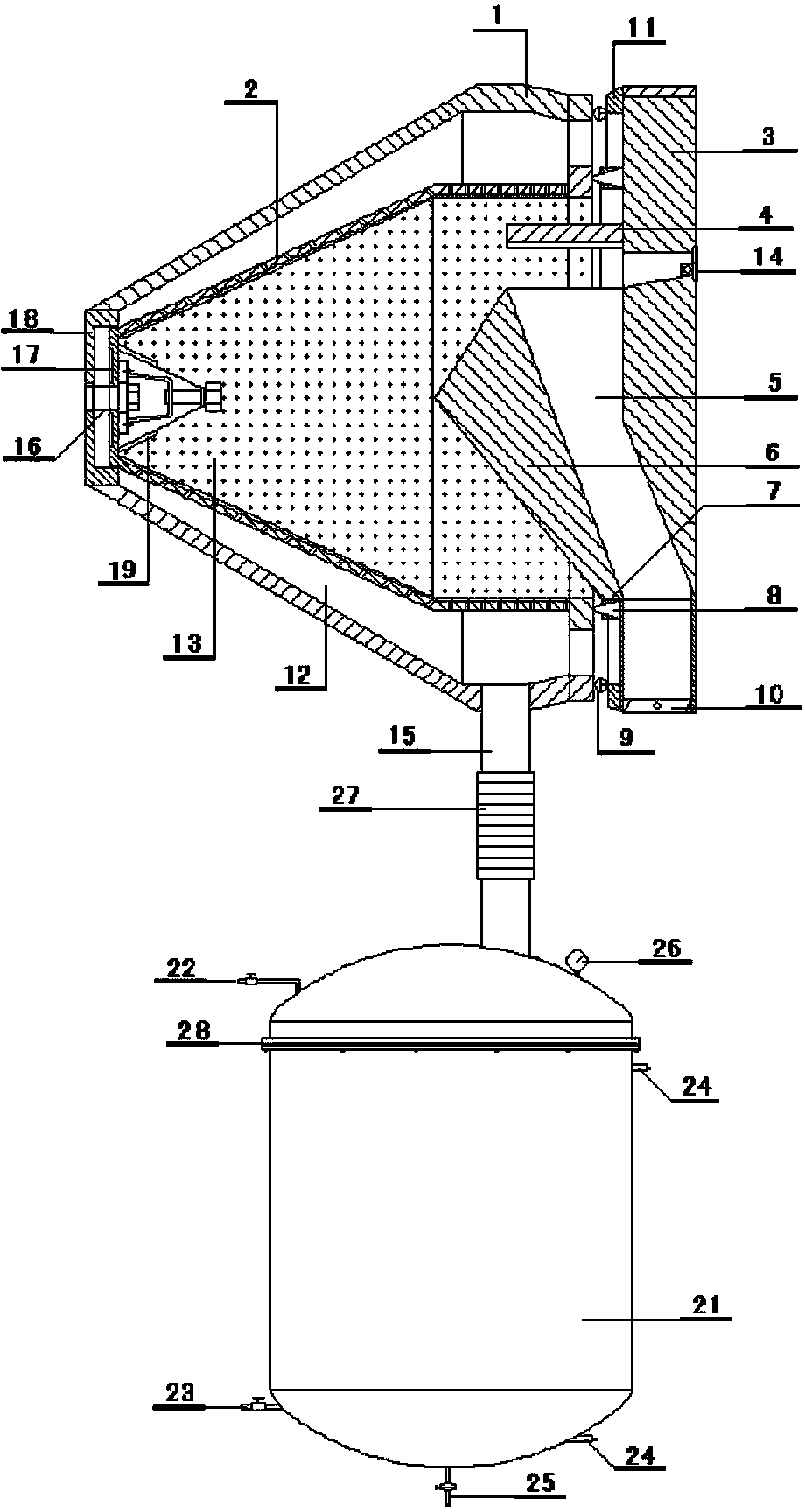

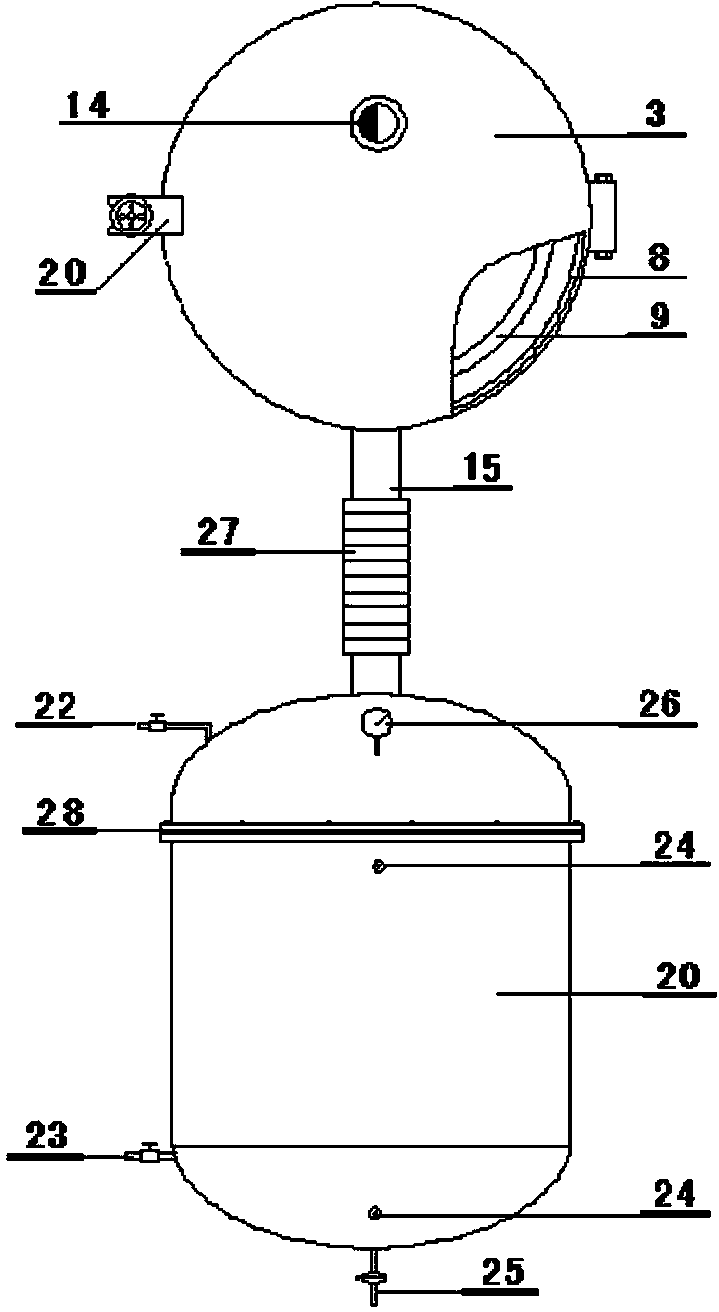

[0012] The dynamic sealing device includes a dynamic sealing door 3, a dynamic sealing assembly and a static sealing assembly, the dynamic sealing assembly is a dynamic sealing ring 8 fixed on the dynamic sealing door 3 through a fixed pressure ring 7, and the dynamic sealing ring 8 corresponds to For the dynamic separation basin 2; the static sealing component is the static sealing ring 9 arranged on the dynamic sealing door 3, and the static sealing ring 9 corresponds to the static separation basin 1.

[0013] The dynamic sealing ring 8 is a capsule-type sealing ring, and the inlet or outlet of the capsule chamber is connected to the circulation system of the working medium.

[0014] The present invention adopts the dynamic sealing ring 8 of capsule structure, which is usually made of heat-resistant silica gel, and the cross section is "Ω" shape, and the two sides of "Ω" are fixed on the dynamic sealing door by fixing the pressure ring 7 3, the lumen is provided with the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com