Three-dimensional suction arm movement mechanism of cellular dust collector

A three-dimensional motion, dust collector technology, applied in mechanical equipment, transmission devices, chemical instruments and methods, etc., can solve the problems of unstable walking, complex structure, deformation and air leakage, etc., to achieve smooth reciprocating motion, high running accuracy, and not easy to relax. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

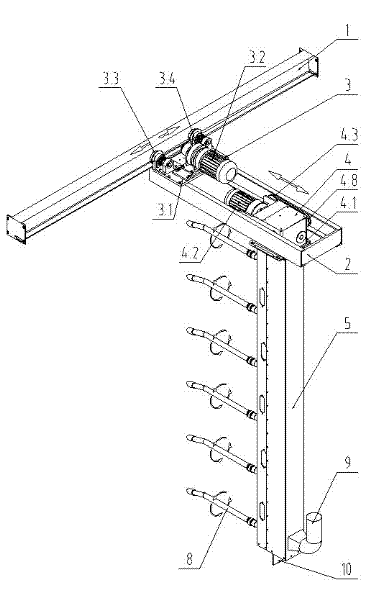

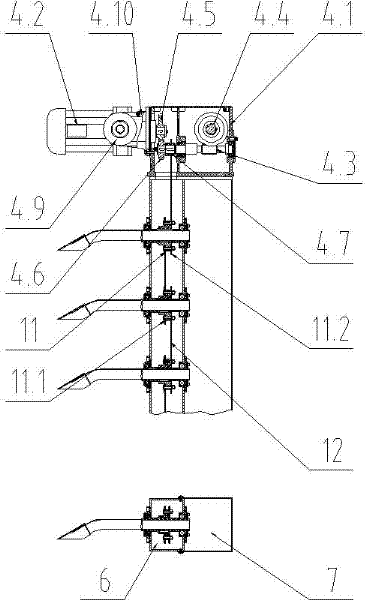

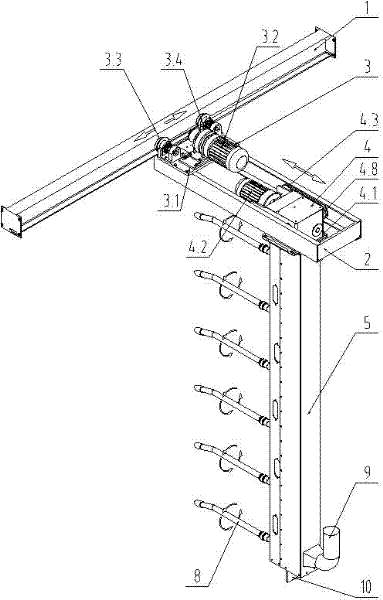

[0042] see figure 1 , figure 2 , the present invention relates to a three-dimensional motion mechanism of a suction arm of a honeycomb dust collector, which includes a horizontal rail 1, a vertical rail 2, a cart 3, a trolley 4 and a transmission suction box 5, the cart 3 is arranged on the horizontal rail 1, and the The longitudinal rail 2 is arranged on the bottom of the trolley 3, the trolley 4 is arranged on the longitudinal rail 2, the transmission suction box 5 is arranged on the bottom of the trolley 3, and the transmission suction box 5 includes a transmission box 6 and a combiner box 7. The transmission box 6 is adjacent to the combiner box 7 and is separated and sealed from each other. The transmission box 6 is equipped with a plurality of rotary suction ports 8 through bearings. One end of the rotary suction ports 8 is bent to 120°, and the rotary suction ports 8 One end extends into the combiner box 7 and communicates with the combiner box 7. The lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com