Vacuum cleaning system

A vacuum cleaning and vacuum technology, applied in cleaning methods and utensils, cleaning methods using gas flow, separation of dispersed particles, etc., can solve the problems of cleaning, small diameter, easy agglomeration of fly ash, etc., and achieve accident prevention and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

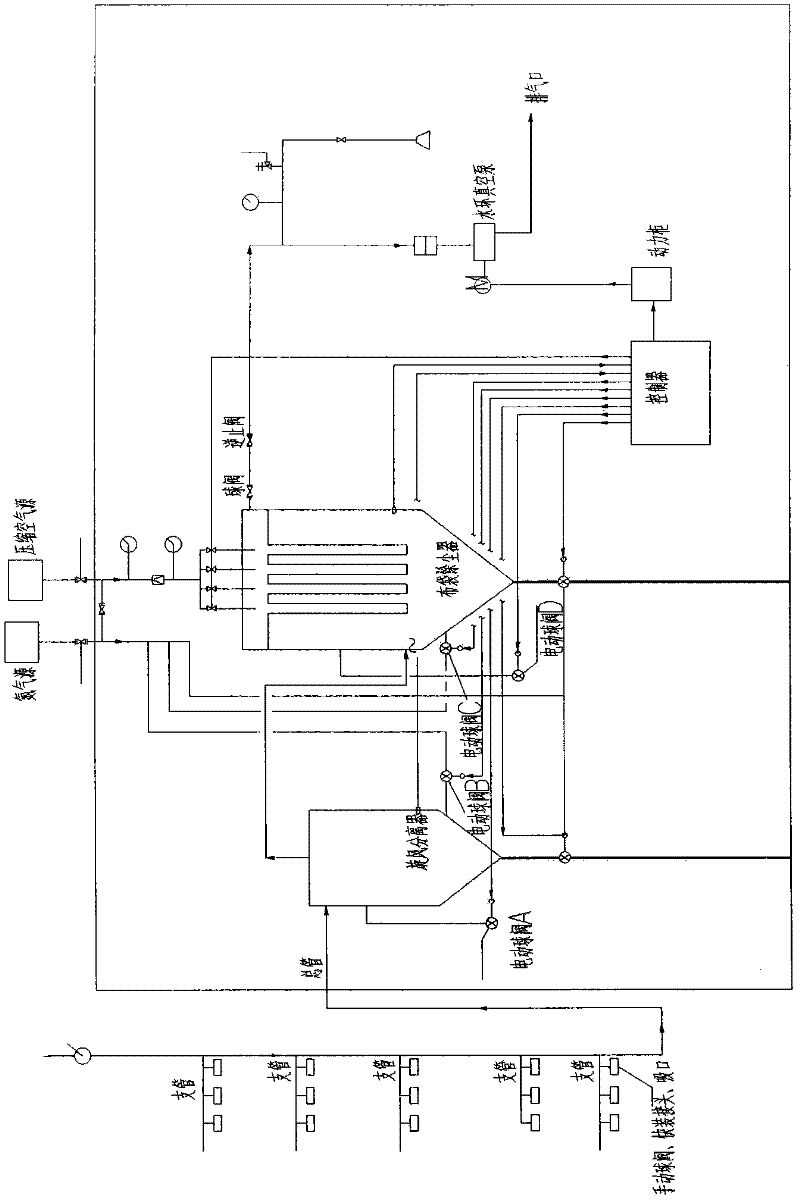

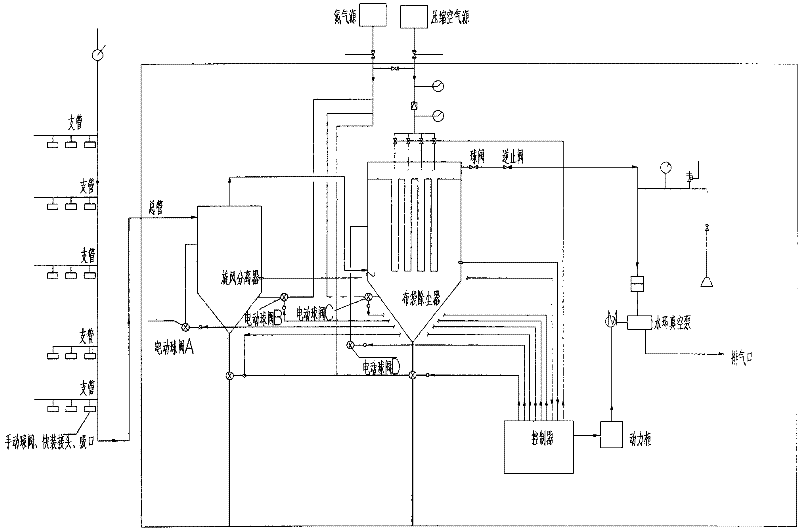

[0019] Below by embodiment, and in conjunction with accompanying drawing, the present invention will be further described:

[0020] As shown in Figure 1 is the best embodiment of the present invention.

[0021] The cyclone separator in the present invention means that the gas enters the cyclone separation area in the equipment through the equipment inlet. When the impurity gas enters the cyclone separation pipe in the axial direction, the air flow is strongly rotated by the guide vane, and the air flow along the cylinder body It enters the cyclone cylinder downwards in a spiral shape, and the dense liquid droplets and dust particles are thrown towards the wall of the device under the action of centrifugal force, and under the action of gravity, they fall along the cylinder wall and flow out of the dust outlet of the cyclone tube to the liquid storage area at the bottom of the equipment , flowing out from the liquid outlet at the bottom of the device. The rotating air flow shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com