Four-point-bending over-bending straightening process method for large shaft tube parts

A four-point bending and process method technology, applied in the mechanical field, can solve the problems of low quality parts, uneven distribution, large residual stress, etc., and achieve the effects of good straightness, reduced straightening times, and increased deformation zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

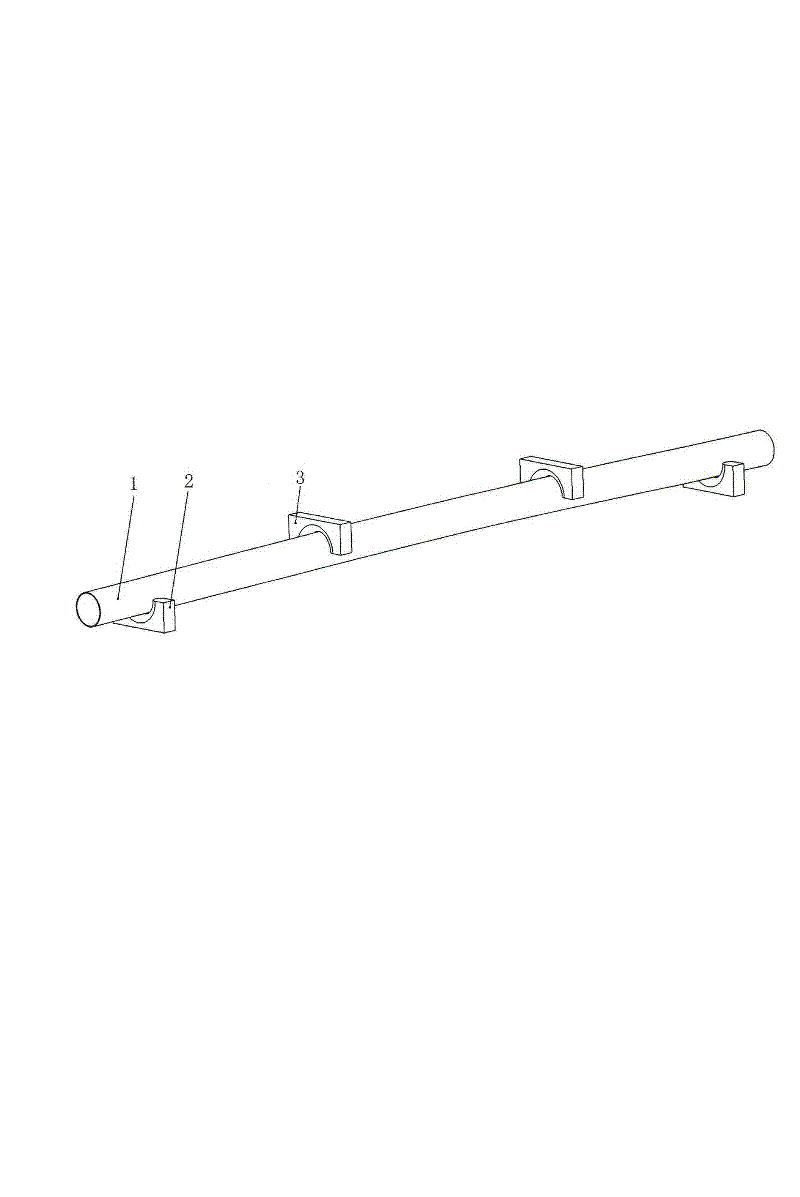

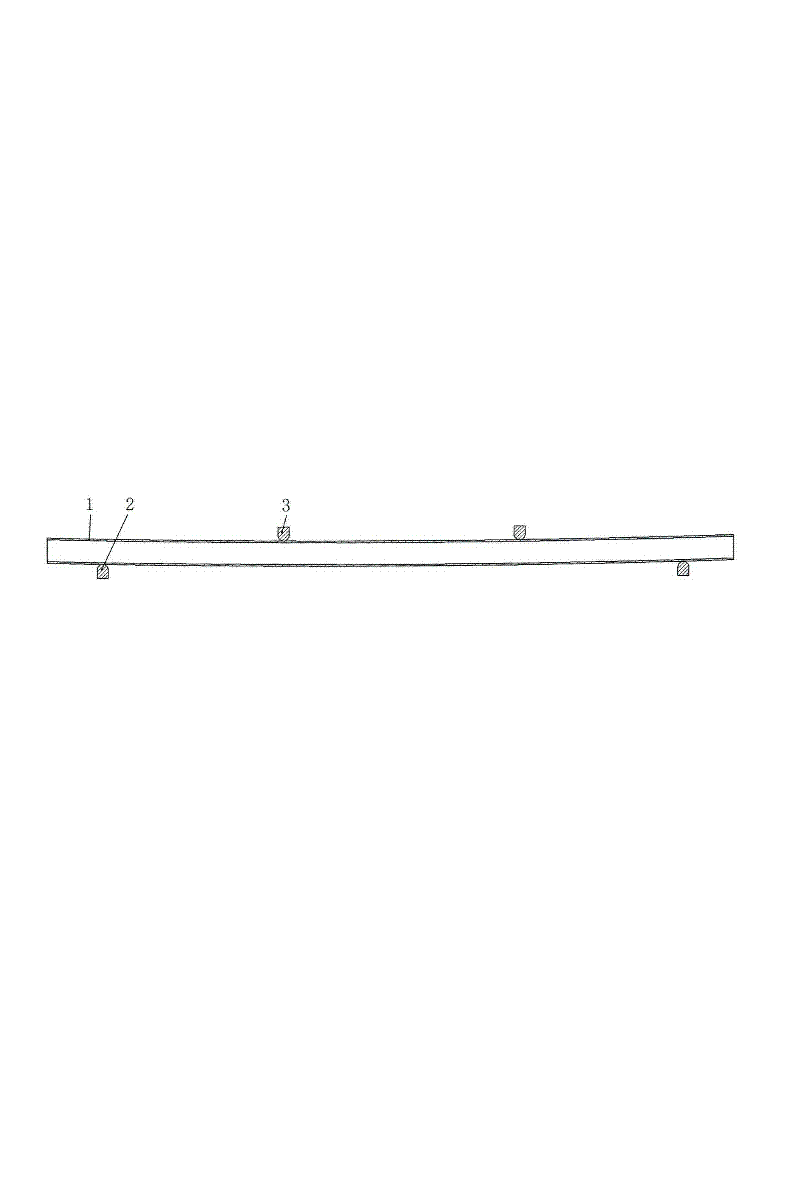

[0024] Example 1: The geometric dimensions of a large longitudinally welded pipe are 457.2 mm in outer diameter, 12.7 mm in wall thickness, 12211 mm in length, and the material is A516Gr60. It can be seen from measurements that its initial deflection is 70 mm. According to the American API Spec 5L industry standard, the straightness of the finished welded pipe, that is, the maximum deflection of the finished pipe, shall not exceed 0.2% of the pipe length, and the length of the pipe is 12211mm, and the final maximum deflection shall not exceed 24mm to meet the straightness requirement. , so it needs to be straightened. It is delivered to the forming press worktable, and placed between two upper molds 3 and two lower molds 2, such as figure 1 shown. The upper ends of the above two upper dies are connected with the beam of the press, and the cross-section of the lower ends is a downwardly convex arc surface. The distance between the two upper dies is adjustable and fixed at 400...

Embodiment 2

[0025] Example 2: Image 6 Shown in is the main schematic diagram of the local working state of Embodiment 2 of the present invention. The upper part of the upper template 13 of the present invention is provided with the same mechanism as the prior art that is connected with the beam of the forming press. The upper edge of the lower surface of the upper template The length and width directions of the upper template are provided with guide grooves, a first vehicle-mounted jack 10 is arranged below, and two independent inserts 4 are arranged on both sides of the first vehicle-mounted jack, by Figure 4 It can be seen that the first vehicle-mounted jack is provided with a vertical guide pin 11, and the upper end of the guide pin is fixed in the width direction guide groove on the upper template. Fix an upper connecting rod 7 with each level of nuts on the two inserts, perforate on both sides of the first vehicle-mounted jack, and pass the screws 9 of the perforations on both side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com