Manufacturing method of rubber mandrel for automotive part

A technology of auto parts and manufacturing methods, applied in the field of auto parts, to achieve the effects of long service life, low cost and increased connection length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

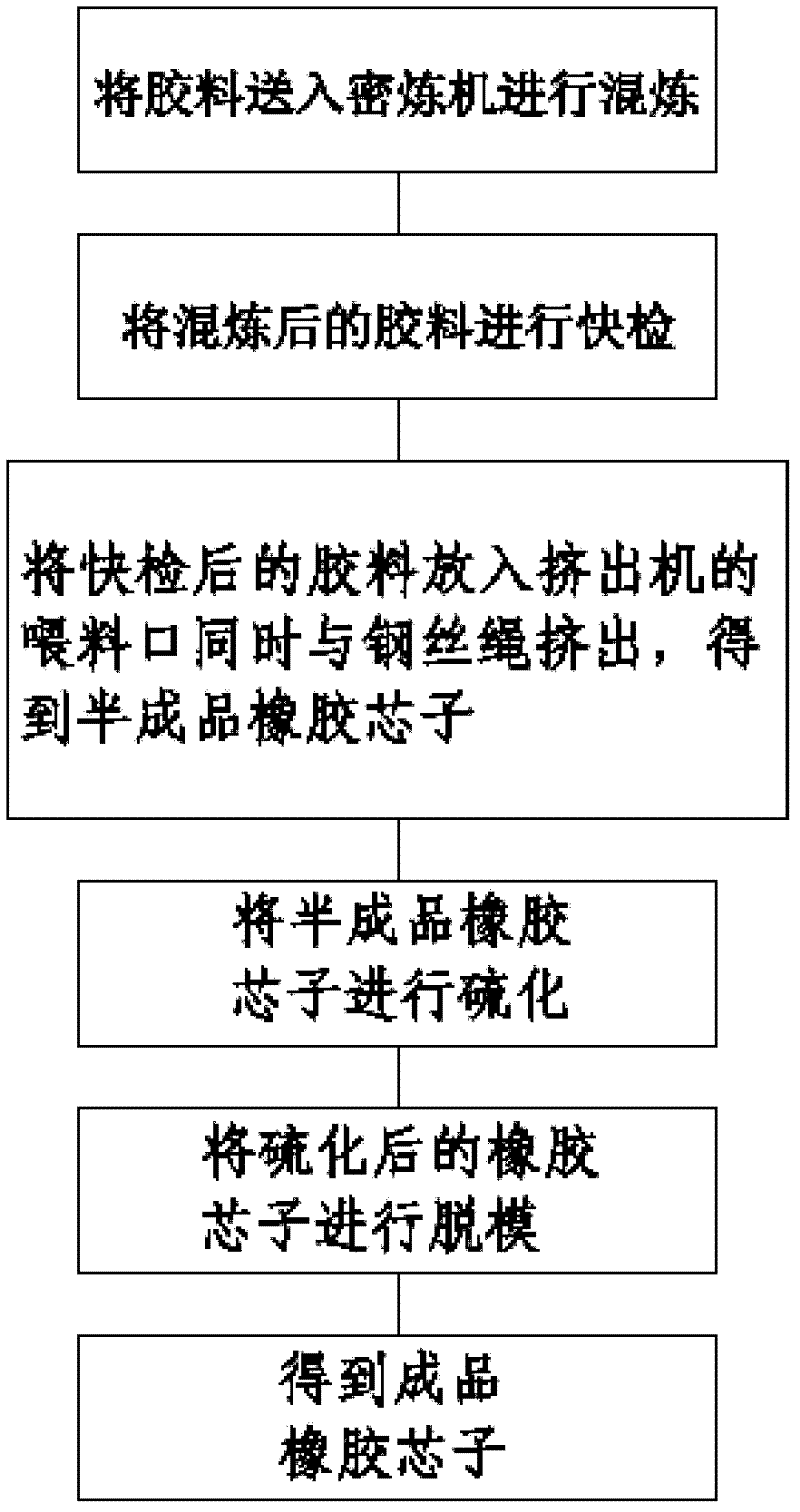

[0027] like figure 1 Shown, the manufacture method of the rubber core that a kind of auto parts of the present invention is used, manufacture method comprises the steps:

[0028] Step 1, the rubber material is sent into the internal mixer for mixing;

[0029] In step 2, the rubber compound after mixing is subjected to a quick inspection test;

[0030] Step 3, put the rubber material in step 2 into the feeding port of the extruder and extrude it with the steel wire rope at the same time to obtain a semi-finished rubber core;

[0031] Step 4, put the semi-finished rubber core of step 3 into a vulcanization tank for vulcanization;

[0032] Step 5, demoulding the vulcanized rubber core;

[0033] Step six, get the finished rubber core.

[0034] The internal mixer described in step 1 is a machine that is equipped with a pair of rotors of specific shape and rotates relatively, and intermittently masticates and kneads polymer materials in a closed state with adjustable temperature...

Embodiment 2

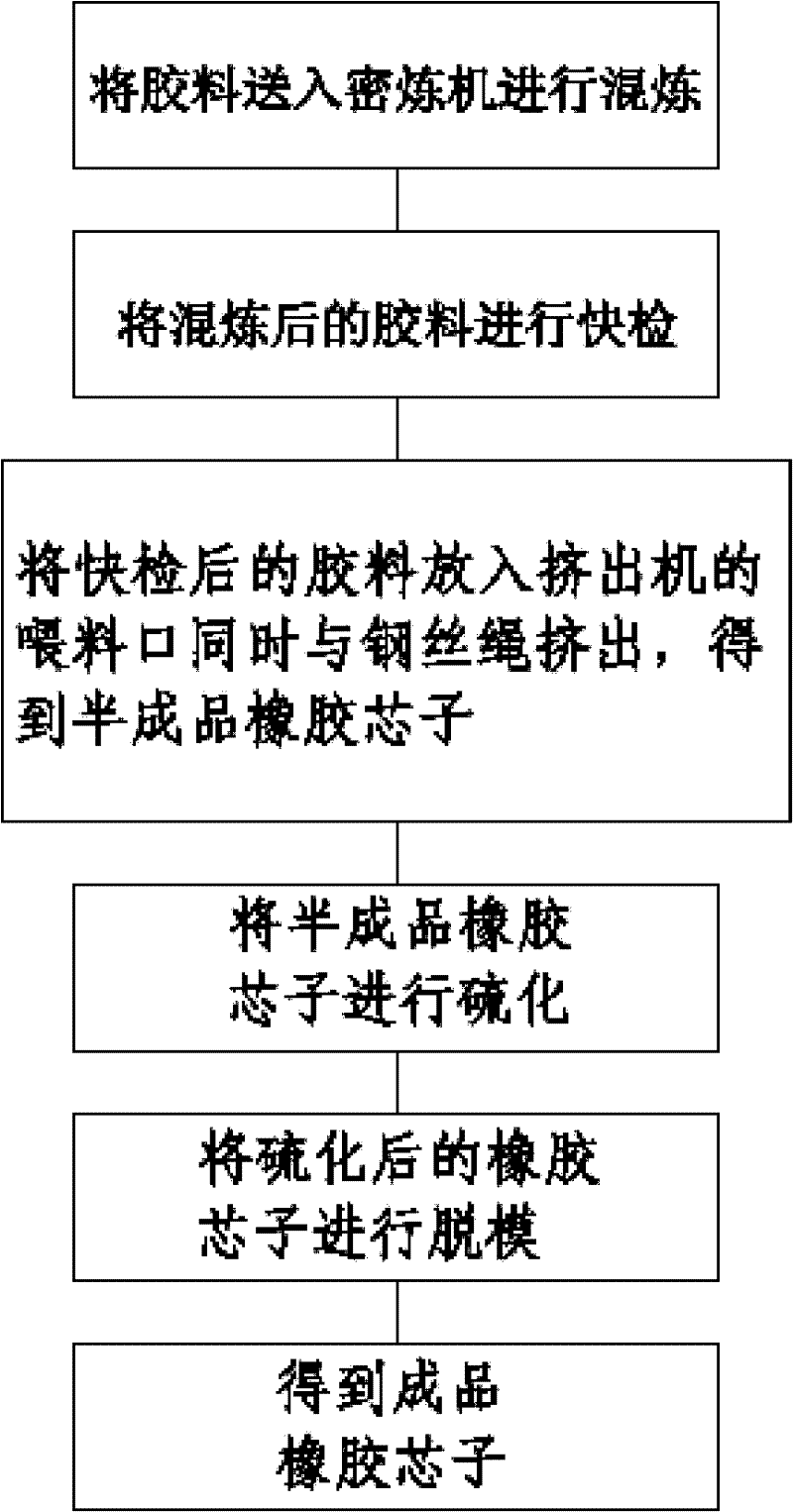

[0044] The manufacturing method comprises the steps of:

[0045] Step 1, the rubber material is sent into the internal mixer for mixing;

[0046] In step 2, the rubber compound after mixing is subjected to a quick inspection test;

[0047] Step 3, put the rubber material in step 2 into the feeding port of the extruder and extrude it with the steel wire rope at the same time to obtain a semi-finished rubber core;

[0048] Step 4, put the semi-finished rubber core of step 3 into a vulcanization tank for vulcanization;

[0049] Step 5, demoulding the vulcanized rubber core;

[0050] Step six, get the finished rubber core.

[0051]The internal mixer described in step 1 is a machine that is equipped with a pair of rotors of specific shape and rotates relatively, and intermittently masticates and kneads polymer materials in a closed state with adjustable temperature and pressure. It is composed of mixing chamber, rotor, rotor sealing device, feeding and pressing device, unloadin...

Embodiment 3

[0061] The manufacturing method comprises the steps of:

[0062] Step 1, the rubber material is sent into the internal mixer for mixing;

[0063] In step 2, the rubber compound after mixing is subjected to a quick inspection test;

[0064] Step 3, put the rubber material in step 2 into the feeding port of the extruder and extrude it with the steel wire rope at the same time to obtain a semi-finished rubber core;

[0065] Step 4, put the semi-finished rubber core of step 3 into a vulcanization tank for vulcanization;

[0066] Step 5, demoulding the vulcanized rubber core;

[0067] Step six, get the finished rubber core.

[0068] The internal mixer described in step 1 is a machine that is equipped with a pair of rotors of specific shape and rotates relatively, and intermittently masticates and kneads polymer materials in a closed state with adjustable temperature and pressure. It is composed of mixing chamber, rotor, rotor sealing device, feeding and pressing device, unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com