Method for improving aziridine cross-linking agent stability

An aziridine crosslinking agent and stability technology, applied in the field of polymer chemistry, can solve problems such as strong volatility, strong odor, difficult transportation and storage, etc., and achieve improved wear fastness, simple post-processing, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

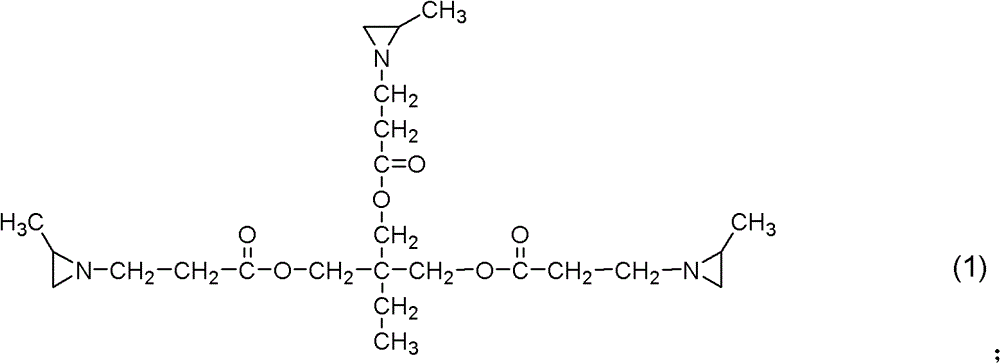

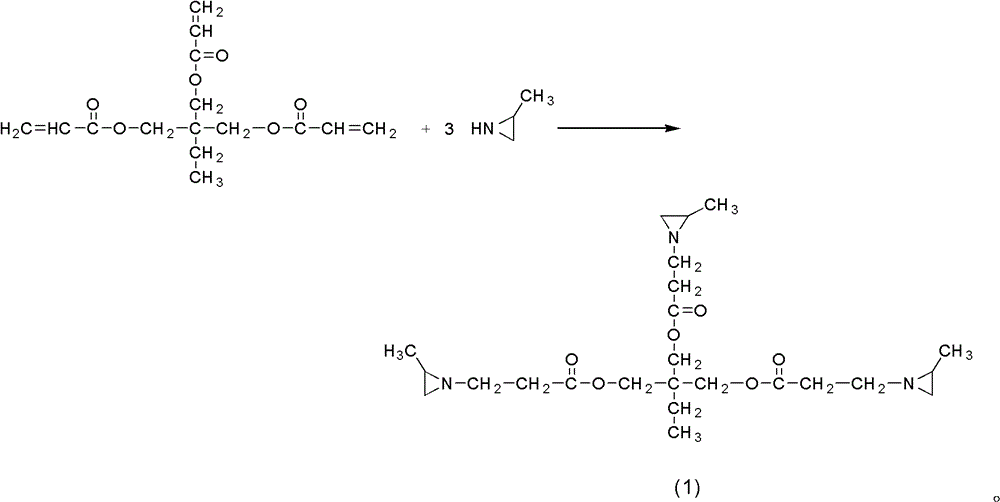

[0034] 1) Preparation of aziridine crosslinker

[0035] In a 1000ml four-neck flask equipped with a stirring, high-efficiency reflux condenser, thermometer, and dropping funnel, add 180 grams (3.15 moles) of 2-methylethyleneimine at room temperature under nitrogen protection, and add 297 grams dropwise with stirring (1 mol) Trimethylolpropane triacrylate (TMPTA), drip in about 30 minutes. After the addition, the temperature was raised to 40-80°C to react for 8 hours. After the completion of the reaction, vacuum distillation is performed for 6 hours, the temperature is 40-80°C, the vacuum degree is 0.1-50mmHg, and the remaining 2-methylethyleneimine is evaporated.

[0036] The product is cooled to room temperature to obtain a pure aziridine crosslinking agent of formula (1), a colorless and clear liquid, weighing 466 grams, with a purity of 99%, and a yield of about 99.5% (calculated as trimethylolpropane triacrylate) ). Gas chromatography analysis showed that the residual amount...

Embodiment 2

[0047] 1) Preparation of aziridine crosslinker

[0048] In a 1000ml four-necked flask equipped with a stirring, high-efficiency reflux condenser, thermometer, and dropping funnel, add 297 grams (1 mole) of trimethylolpropane triacrylate (TMPTA) at room temperature and under nitrogen protection, and drop with stirring. Add 189 grams (3.3 moles) of 2-methylethyleneimine, and the dripping takes about 1 hour. After the addition, the temperature was raised to 40-80°C to react for 6 hours. After the completion of the reaction, vacuum distillation is performed for 6 hours, the temperature is 40-80°C, the vacuum degree is 0.1-50mmHg, and the remaining 2-methylethyleneimine is evaporated.

[0049] The product is cooled to room temperature to obtain a pure aziridine crosslinking agent of formula (1), a colorless, clear and viscous liquid, weighing 464 grams, with a purity of 99%, and a yield of about 99% (based on trimethylolpropane triacrylic acid) Esters). Gas chromatographic analysis s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com