Low temperature power type hydrogen storage alloy for nickel-metal hydride battery

A technology for hydrogen storage alloys and nickel-metal hydride batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of decreased self-discharge performance of alloys, aggravated corrosion of nickel-metal hydride batteries, and easy volatilization, and achieves low temperature and improved power performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

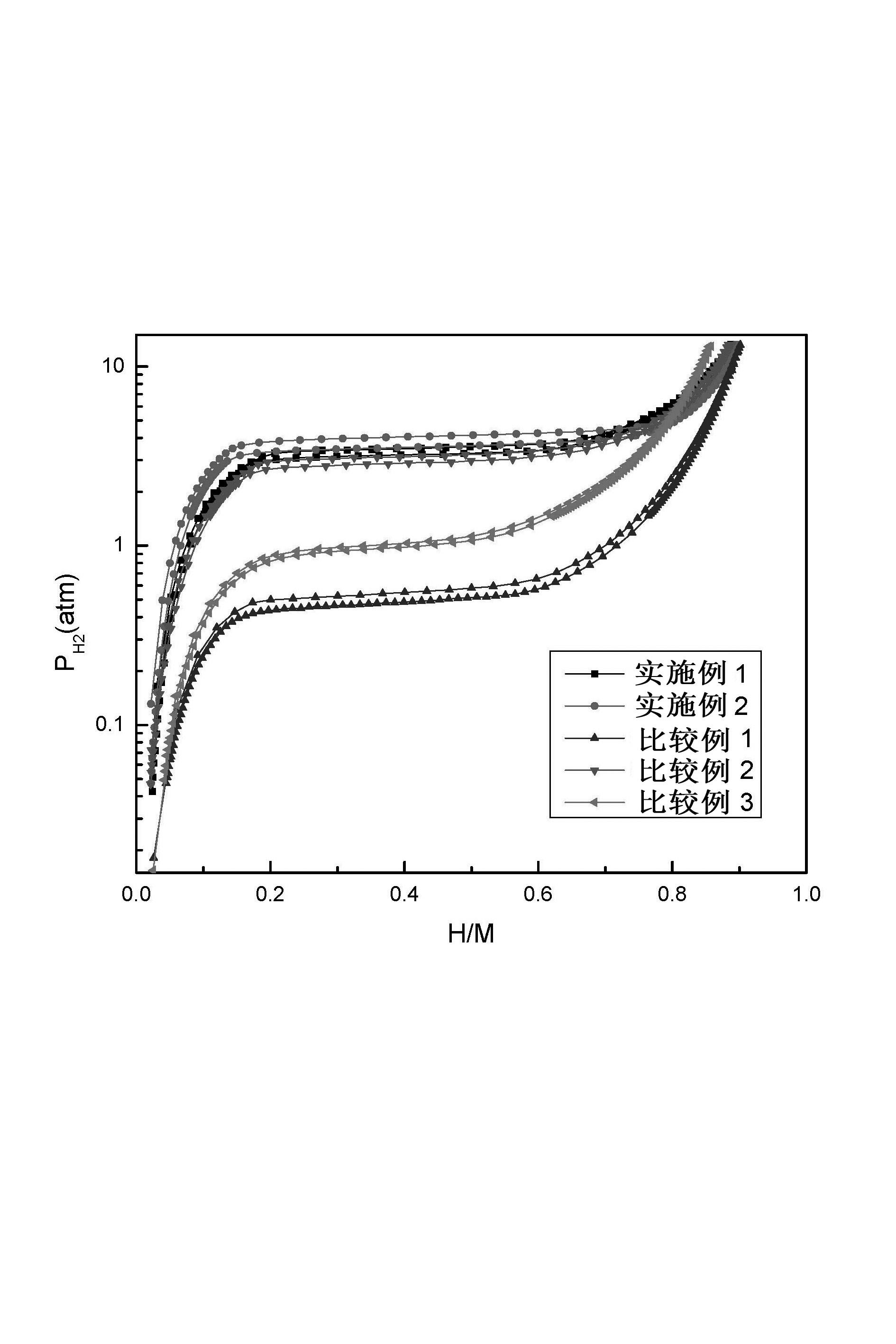

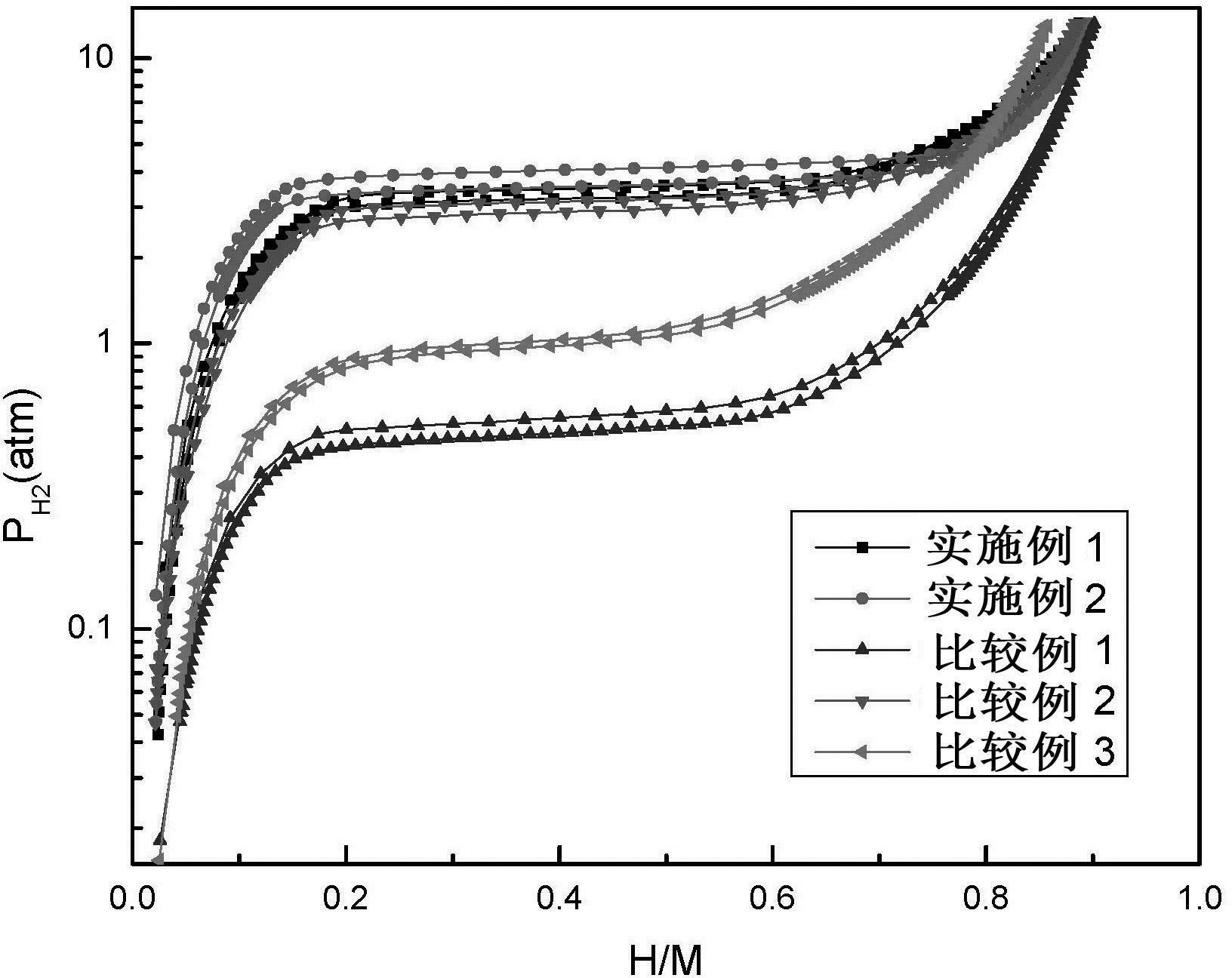

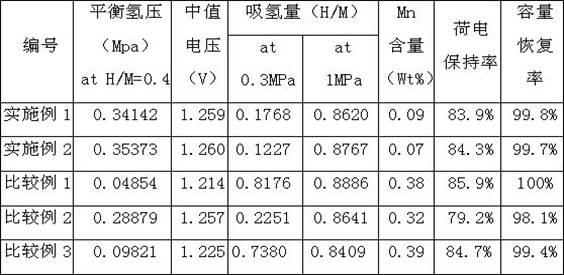

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below, but the present invention is not limited thereto, and the present invention can also be implemented by making appropriate adjustments within the scope of not changing the claims of the present invention.

[0021] "%" in the examples are all "wt%".

[0022] 1) Alloy preparation method:

[0023] Preparation of La (purity >99.5%), Mm (La: 30%, Ce: 50%, Pr: 5%, Nd: 15%; La+Ce+Pr+Nd >99%), Ni (purity >99.5%) , Co (purity>99.5%), Mn (purity>99.5%), Al (purity>99.5%) total 5kg. Put the raw metal into Al in the order of Al, Mn, Ni, Co, La, Mm from bottom to top 2 o 3 in the crucible. First evacuate to 3Pa, then bake and wash the furnace, fill with argon to 0.05MPa, gradually adjust the power of 4kw, 6kw, 8kw, 10kw for 5 minutes each, control the temperature at 1500℃±30℃, and then refine for 3 minutes; Argon to 0.05MPa, the melt is poured and passed through a water-cooled copper roller (line speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com