Method for preparing boric acid from crude boron stone through electroosmosis electrolytic method

An electrolysis method and ore technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult sulfate content, high ore grade requirements, and increased processing costs, and achieve wide applicability of raw materials, good economic benefits, The effect of material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

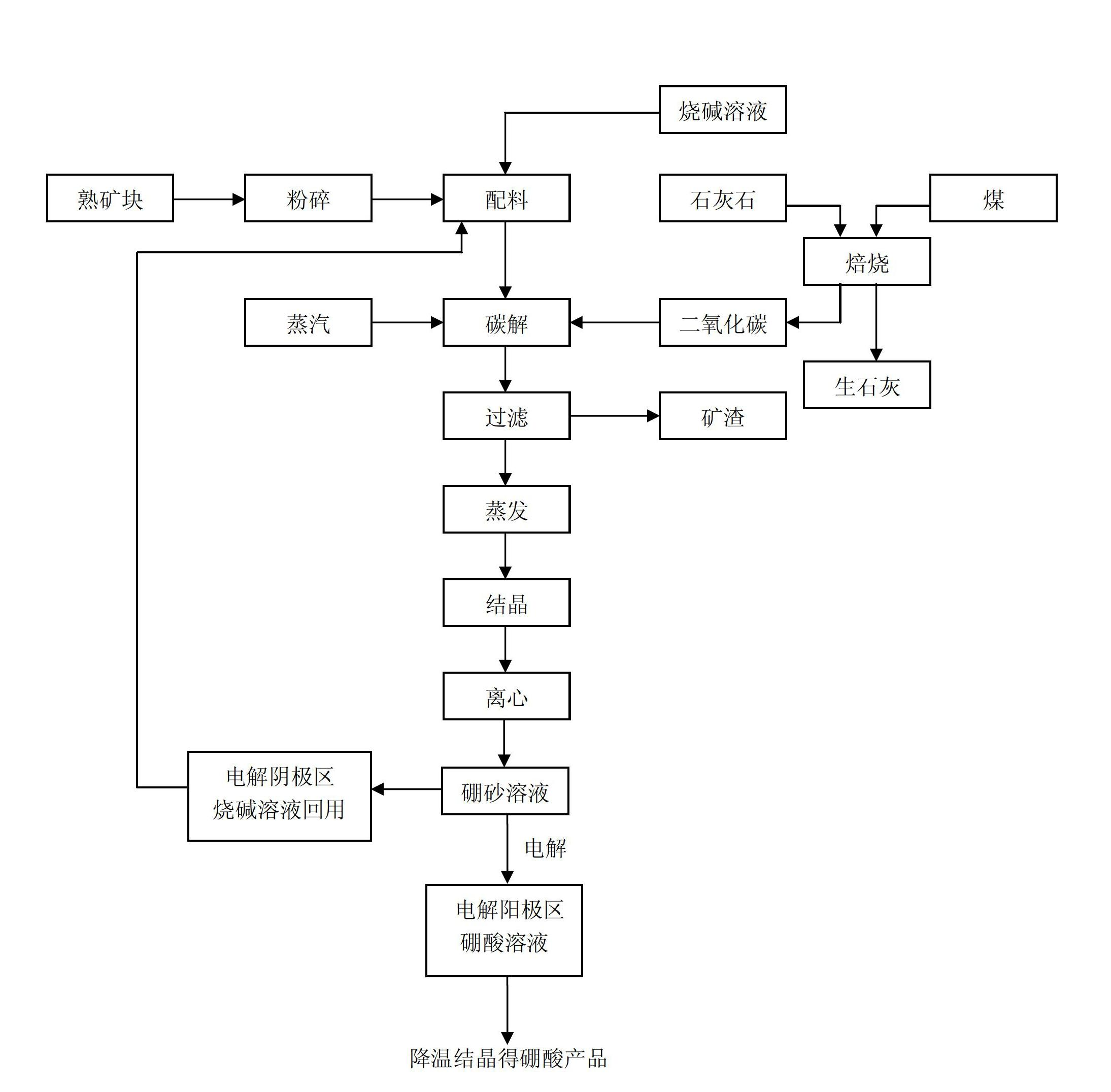

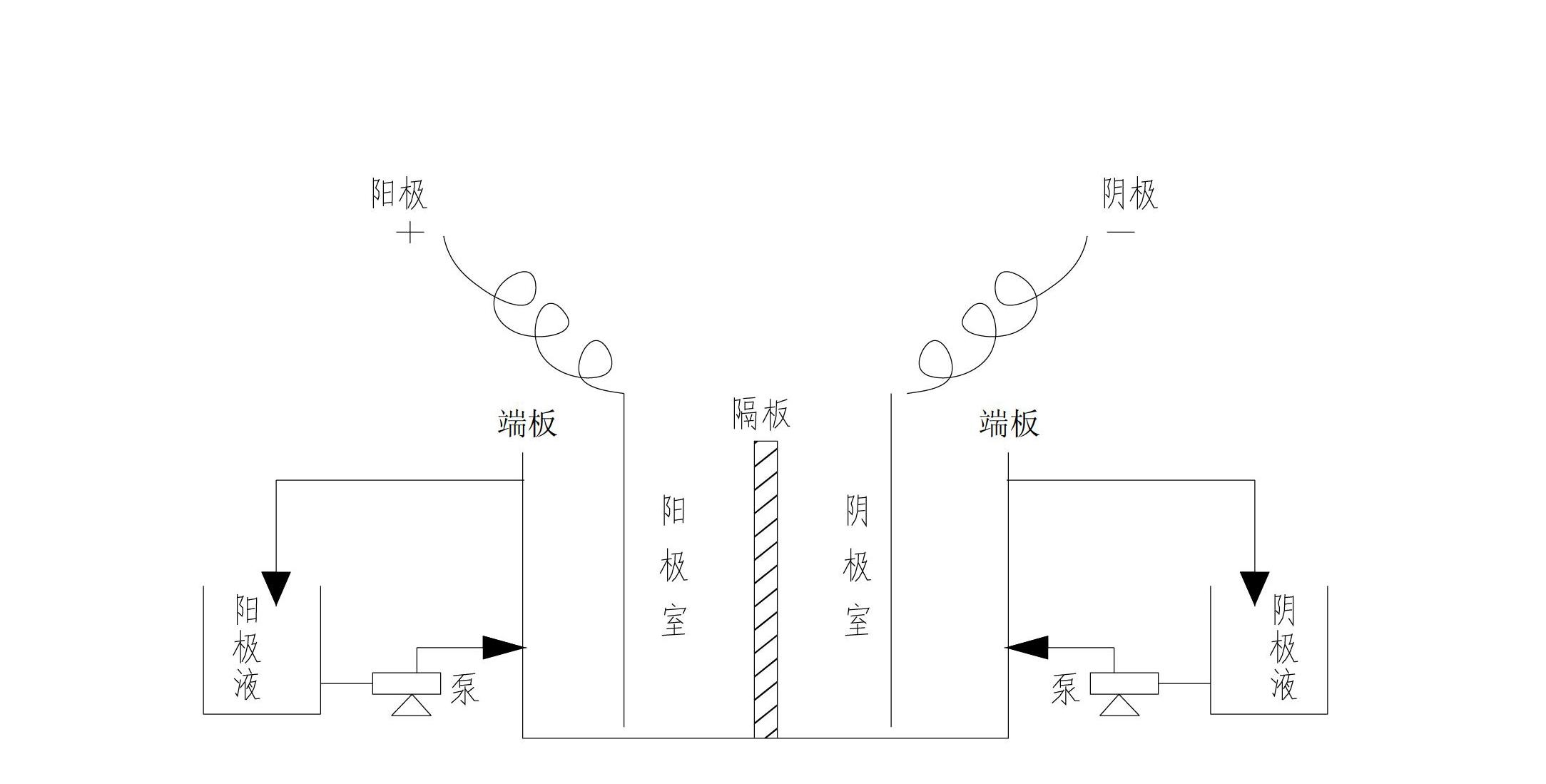

[0026] In this embodiment, boron ore with a boron content ≥ 9% is used. After roasting at a temperature of 600° C., it is crushed and ground into ore powder with a particle size ≥ 60 mesh. Configure 10% caustic soda solution, put 400Kg of ore powder and 500Kg of caustic soda solution into the carbonization furnace, keep the temperature of the carbonization furnace at 120°C, and the pressure at 0.6MPa, and react for 7.5 hours. Filter the reacted slurry for a second time. After crystallization, the borax content in the remaining filtrate is about 5%, and put it into the anode area of the electroosmotic electrolysis device, and put 6% caustic soda solution in the cathode area. The distance between the parallel electrolytic cell end plate and the ion selective permeable membrane is 2 mm, the temperature of the yin and yang areas is 50 ° C, the electrolytic DC voltage is 3.0 V, and the electrolytic reaction time is 4 hours. The detection purity reaches 99.5%.

Embodiment 2

[0028] In this embodiment, boron ore with a boron content ≥ 12% is used. After roasting at a temperature of 700° C., it is crushed and ground into ore powder with a particle size ≥ 60 mesh. Configure 20% caustic soda solution, put 1000Kg of ore powder and 1300Kg of caustic soda solution into the carbonization furnace, keep the temperature of the carbonization furnace at 130°C, and the pressure at 0.6MPa, and react for 10 hours. Filter the reacted slurry for a second time. After crystallization, the borax content in the remaining filtrate is about 12%, and put it into the anode area of the electroosmotic electrolysis device, and put 9% caustic soda solution in the cathode area, and the anode and anode chambers and the cations selectively permeate the membrane phase The distance between the parallel electrolytic cell end plate and the ion selective permeable membrane is 70 mm, the temperature of the yin and yang areas is 60 ° C, the electrolytic DC voltage is 4.3 V, and the ele...

Embodiment 3

[0030] In this embodiment, boron ore with a boron content ≥ 9% is used. After roasting at a temperature of 700° C., it is crushed and ground into ore powder with a particle size ≥ 60 mesh. Configure 30% caustic soda solution, put 2000Kg of ore powder and 2800Kg of caustic soda solution into the carbonization furnace, keep the temperature of the carbonization furnace at 130°C, and the pressure at 0.7MPa, and react for 10 hours. Filter the reacted slurry for a second time. After crystallization, the borax content in the remaining filtrate is about 16%. Put it into the anode area of the electroosmotic electrolysis device, and put 20% caustic soda solution in the cathode area. The distance between the parallel electrolytic cell end plate and the ion selective permeable membrane is 140mm, the temperature of the anodic and anode areas is 70°C, the electrolytic DC voltage is 5.5V, and the electrolytic reaction time is 10 hours. The detection purity reached 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com