Cable type downhole descaling device

A technology for cables and transmission devices, applied in the field of cable-type underground descaling devices, can solve the problems of easily corroded underground tools, serious pollution, and easily damaged tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

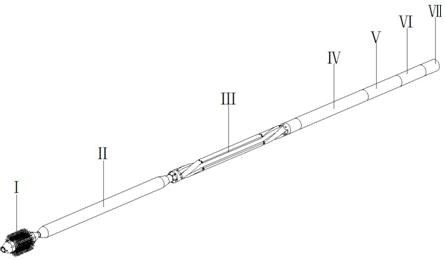

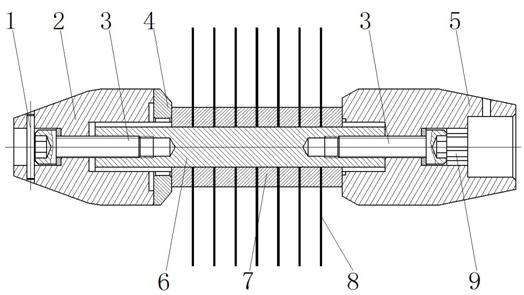

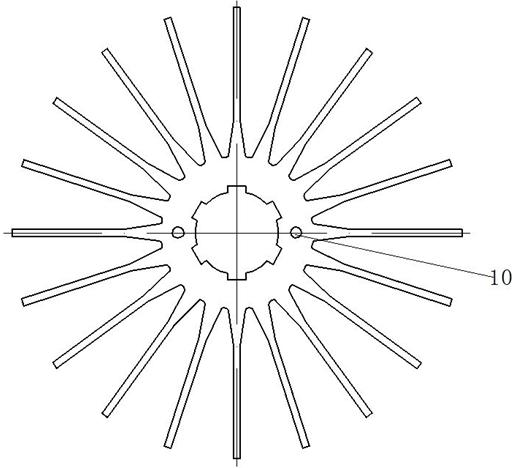

[0017] Depend on figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a cable-type downhole descaling device includes steel brush head Ⅰ, transmission device Ⅱ, anchor Ⅲ, electric motor Ⅳ, pressure compensator Ⅴ, controller Ⅵ and cable joint Ⅶ connected in sequence, and its characteristics are : All components are threaded, the steel brush head I is composed of steel brush plate 8, spacer bush 7, hexagon socket head screw 3, cylindrical pin 1, spline shaft 6, shaft sleeve 4, left locking joint 2 and the right locking joint 5; the star-shaped steel brush disc 8 with a spline hole in the center has good elastic properties, and its thickness is between 0.4 and 1.0mm. It is installed on the spline shaft 6, and the two steel Spacer bushings 7 are installed between the brush discs 8; round holes 10 fitted with the circular bosses 11 of the spacer bushes are arranged on the steel brush discs 8; the left locking joint 2 and the right locking joint 5 are both Conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com