Squeezing and twisting combined-type elastic coupler

An elastic coupling and composite technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of noise, transmission system vibration, and can not compensate for angular displacement well, and achieve transmission noise. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

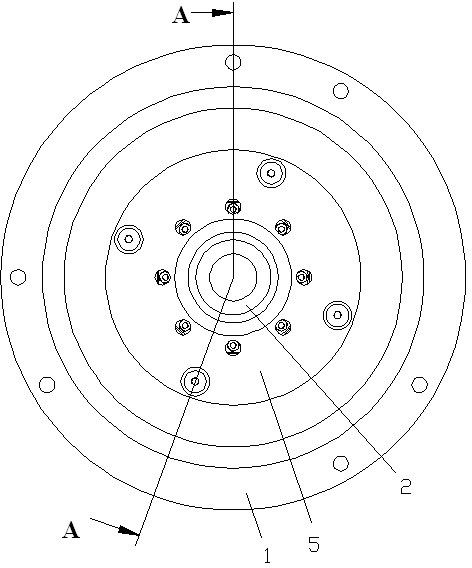

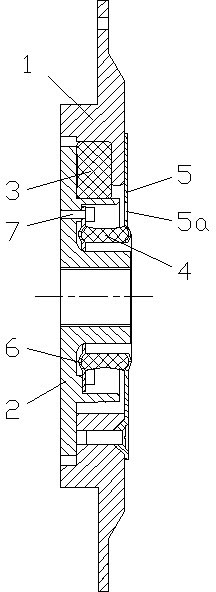

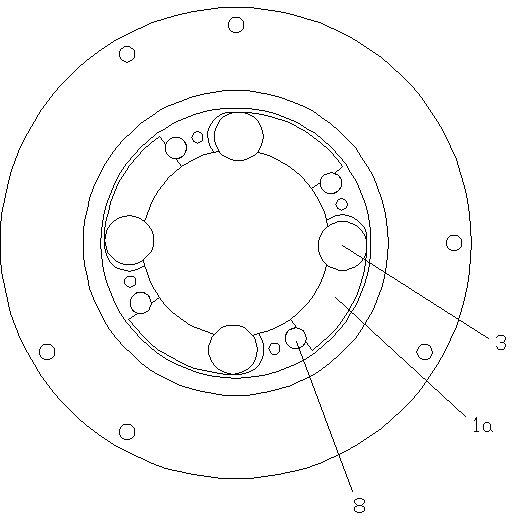

[0018] The extrusion and torsion composite elastic coupling in this embodiment includes an input disc 1, an output disc 2, an extruded rubber block 3 and a torsion transmission assembly;

[0019] The input disk 1 is provided with an arc-shaped groove 1a extending along its circumferential direction, the number of the arc-shaped grooves 1a is four and evenly arranged along the circumferential direction of the input disk 1, and the extruded rubber block 3 is arranged in the arc-shaped groove In 1a, the output disk 1 is provided with a protrusion 2a that extends into the arc-shaped groove 1a and can move along the arc-shaped groove; When the pressing rubber block 3 rotates to contact with the bump 2a on the output disc 2, the pressing rubber block 3 will push the bump 2a to rotate, thereby transmitting the power from the input disc 1 to the output disc 2;

[0020] The torsion transmission assembly includes a torsion rubber sleeve 4, a first transmission piece 5 fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com