System and method using electronic deflection to form flying spot

An electronic deflection and flying spot technology, applied in the field of X-ray imaging, can solve the problems of limited flying spot moving speed, slow moving speed of flying spot, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

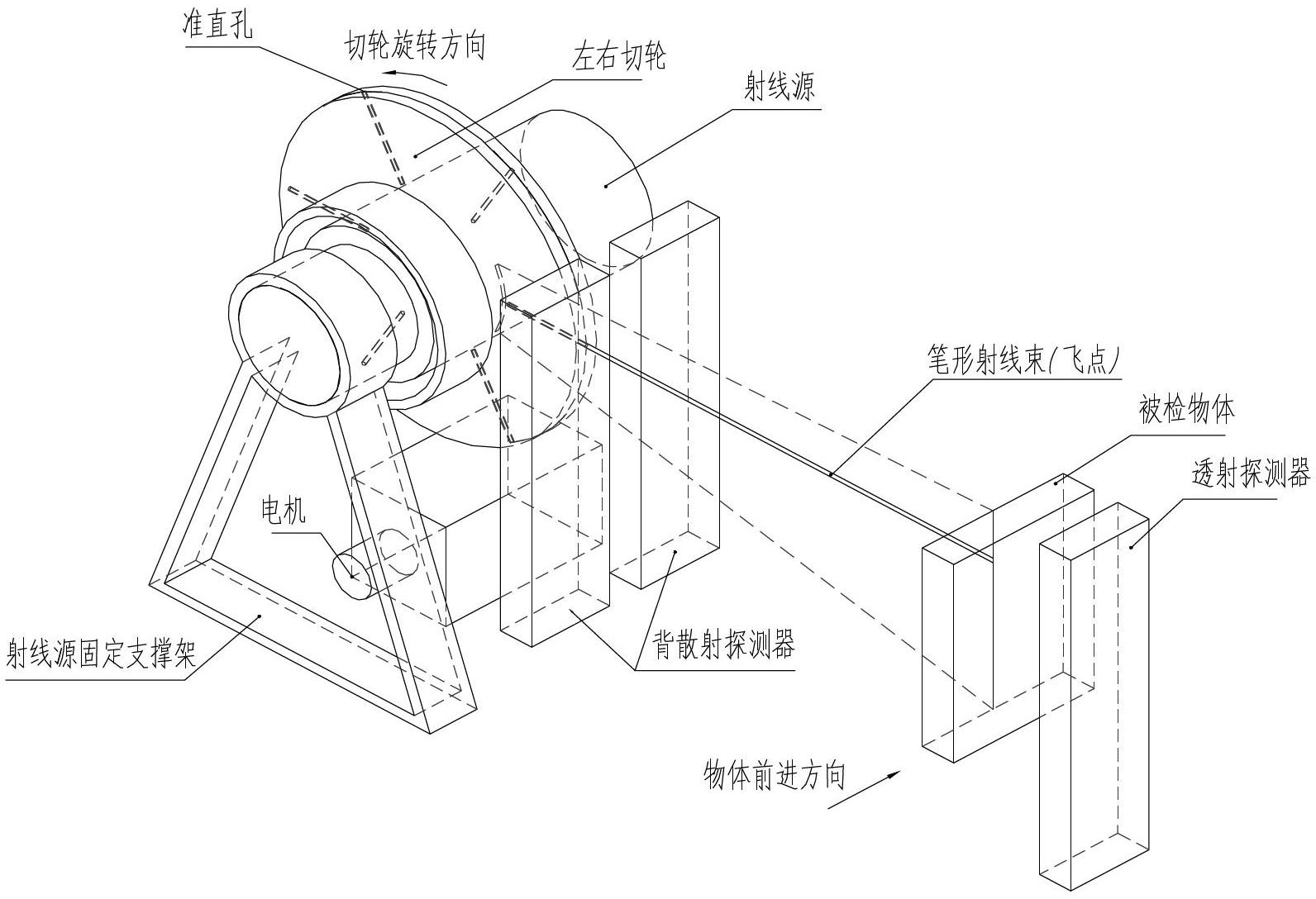

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

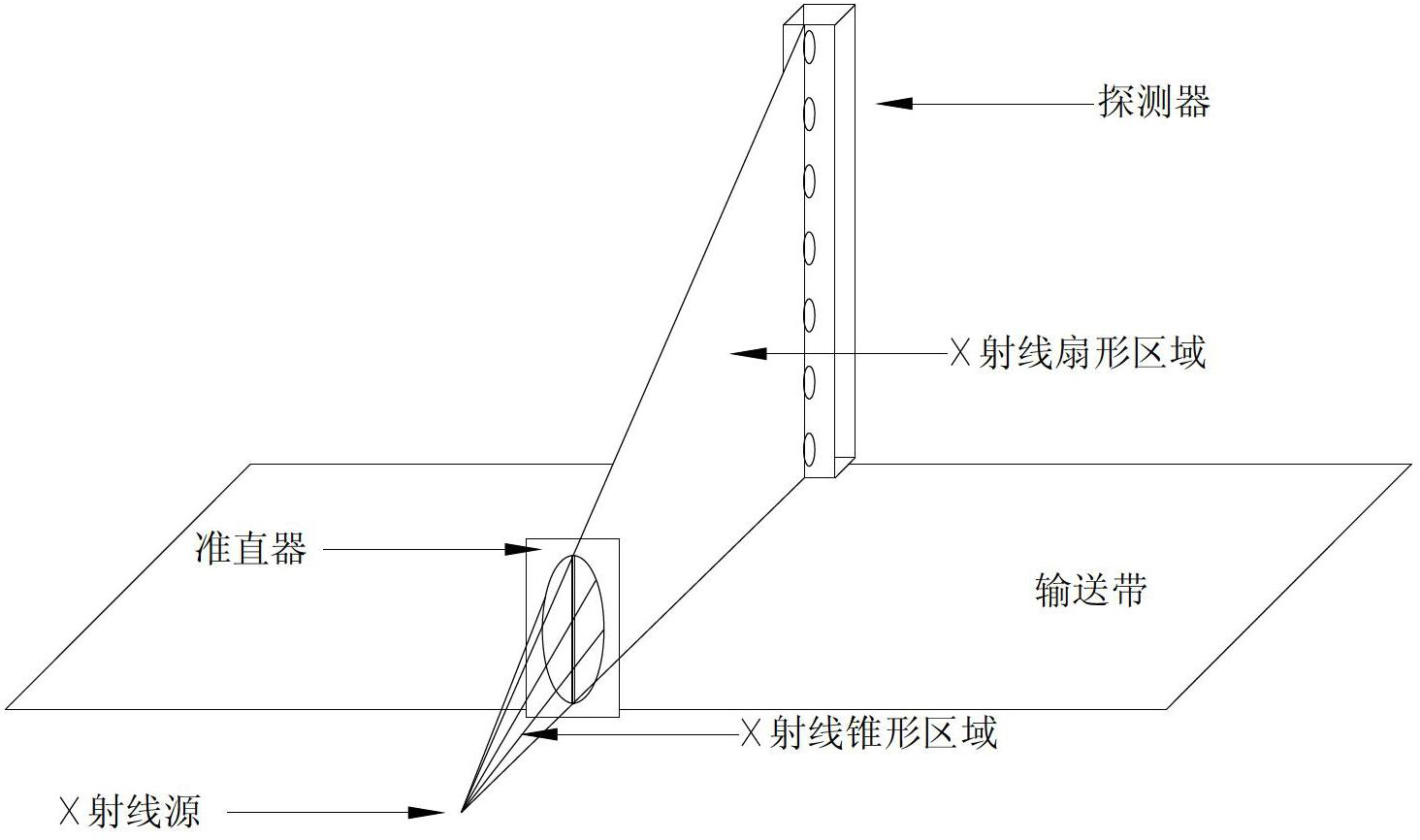

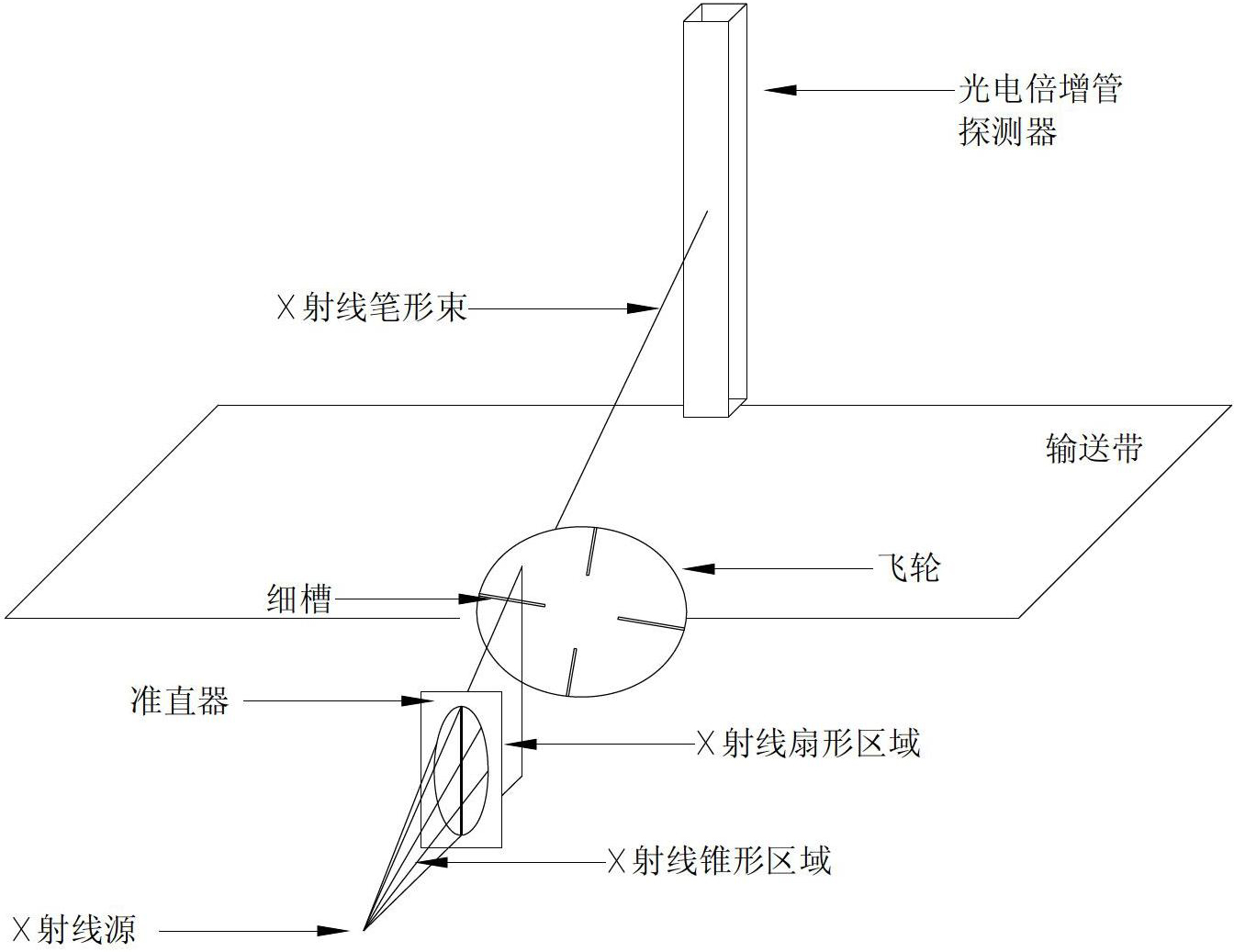

[0033] like Figure 4 As shown, it is a schematic composition diagram of a system using electronic deflection to form flying spots according to an embodiment of the present invention. The system includes:

[0034] X-ray source, the X-ray source has a deflection coil, the magnetic field of the deflection coil deflects the electrons emitted by the cathode to form deflected electrons, and the deflected electrons fall on the anode target to form an X-ray beam;

[0035] A pinhole device, the pinhole device is located at the beam output window of the ray source, and transmits the X-ray beam to form flying spots.

[0036] In the embodiment of the present invention, the target point of the X-ray source can be changed, and the change of the target point is realized by deflecting the target electrons by the magnetic field, and then cooperates with the pinhole device t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com