Method and device for fully closed-loop control of electric heating upsetting temperature

An electric heating upsetting and fully closed-loop technology, which is applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as low control accuracy, inability to control temperature, and deterioration of product quality consistency, achieving high precision, The effect of more temperature control and stable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

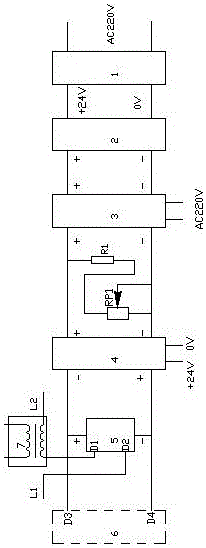

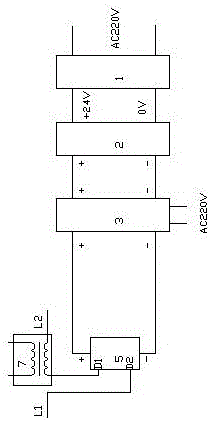

[0019] Embodiment 1. A method for fully closed-loop control of the temperature of the electric heating upsetting. During the electric heating upsetting process, the colorimetric infrared thermometer 2 is used to measure the heating temperature of the electric heating upsetting, and the electric heating is controlled by the temperature controller 3, the power regulator 5 and the heating transformer 7. Upsetting heating voltage, so as to realize the full closed-loop control of electric heating upsetting temperature.

[0020] The specific control process is as follows:

[0021] In the temperature controller 3, set the allowable maximum temperature value in the electric heating upsetting process, and the control mode is cooling mode. When the temperature of the electrothermal upsetting measured by the colorimetric infrared thermometer 2 is lower than the set temperature, the input signal of the power regulator 5 is given by the microcomputer or other voltage setting device 6, and ...

Embodiment 2

[0024] Embodiment 2. A method for fully closed-loop segmentally controlled electric heating upsetting temperature. When the temperature of the entire electric heating upsetting process needs to be controlled in segments, a temperature controller 3 with segmental control function or communication function is used. The temperature value of each segment is set in the controller 3, or the signal is input to the temperature controller 3 through an external setting and then through communication input, and the temperature controller 3 controls the temperature of the entire electric heating upsetting process in sections.

[0025] The specific control process is as follows:

[0026] In segmental control, the whole process of electric heating upsetting is divided into multiple time periods, and the heating temperature of each time period is preset. When the temperature measured by colorimetric infrared thermometer 2 reaches the temperature set by temperature controller 3 When the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com