High-dielectric-material super capacitor with porous structure

A high-dielectric material and porous structure technology, applied in capacitor electrodes, capacitor parts, capacitor dielectric layers, etc., can solve the problems of poor safety, small leakage current, low power density, etc. Energy storage density, the effect of increasing the capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

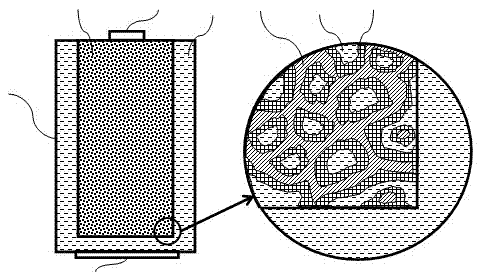

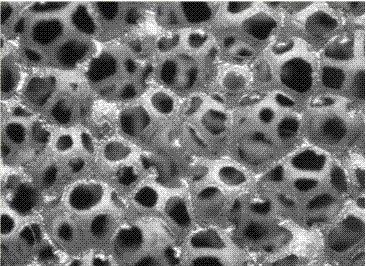

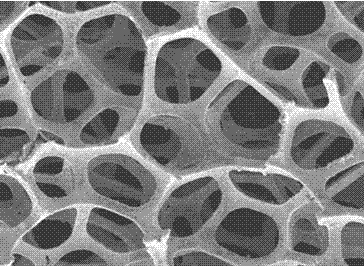

[0029] Such as figure 1 As shown, the high dielectric material porous structure supercapacitor includes a porous metal high dielectric material composite substrate 1, a low melting point metal medium 2, a sealed container 3, a positive electrode 4, and a negative electrode 5; the porous metal high dielectric material composite substrate 1 is A porous material formed by depositing one or more layers of high dielectric material 7 on the surface of the metal foam skeleton 6, the porous metal high dielectric material composite substrate 1 is soaked in the low melting point metal medium 2, and is packaged in a sealed container 3, The porous metal high dielectric material composite substrate 1 is connected to the positive electrode 4, and the conductive liquid medium 2 is connected to the negative electrode 5 to form a supercapacitor for accumulating electric energy.

[0030] The high dielectric material 7 is BaTiO 3 or CaCu 3 Ti 4 o 12 High dielectric constant material, or two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com