Lead plaster composition for manufacturing positive plate of lead-acid storage battery, positive plate of lead-acid storage battery and lead-acid storage battery

A lead-acid battery, positive plate technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve the problem that the charging acceptability needs to be further improved, and achieve the effect of improving the charging acceptability, facilitating application, and enhancing conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

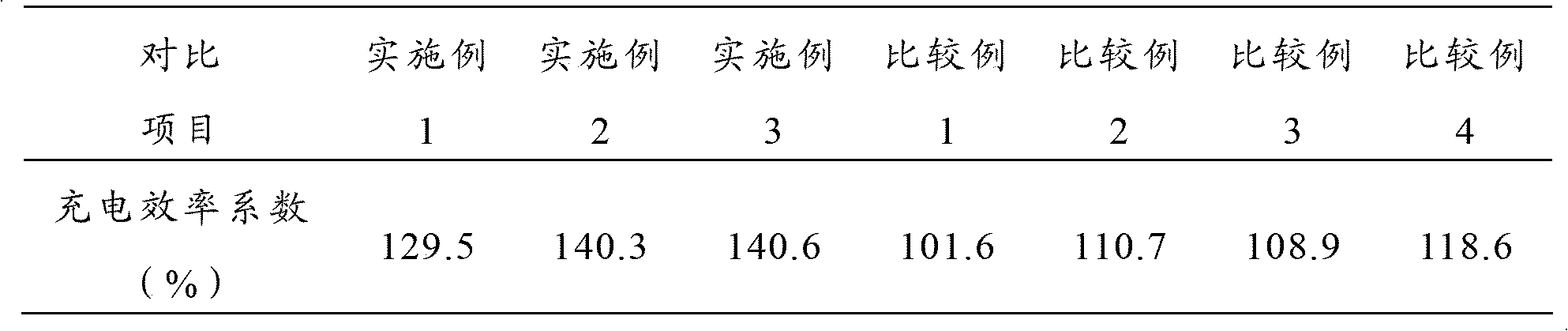

Examples

Embodiment 1

[0070] Mix 800kg lead powder, 1kg polypropylene staple fiber with a length of 1.5mm, 1kg graphite powder and 1kg PTFE emulsion, add 120kg water and 77kg with a density of 1.35g / cm 3 The sulfuric acid is stirred to obtain a slurry, which is the lead paste composition used to manufacture the positive plate of the lead-acid storage battery;

[0071] A lead alloy containing 0.08%Ca, 0.15%Sn, 0.04%Al and the balance of Pb in weight percentage is made into a grid sample, and placed in a density of 1.28g / cm 3 In sulfuric acid, at an ambient temperature of 25±2°C, at 5.0mA / cm 2 Constant current anodic polarization for 500h, and then remove oxides in hot alkali solution, calculated according to corrosion weight loss and sample surface area, the corrosion rate is 0.130mg / (cm 2 h), 3.112mg / (cm 2 ·d), repeat the above operation and calculate, the corrosion rate is 0.112mg / (cm 2 h), 2.651mg / (cm 2 d);

[0072] Coating the obtained lead paste composition on the grid made of the above-me...

Embodiment 2

[0078] Mix 850kg lead powder, 1.5kg polypropylene staple fiber with a length of 2mm, 2kg graphite powder and 0.5kgPTFE emulsion, add 100kg water and 46kg density of 1.4g / cm 3 The sulfuric acid is stirred to obtain a slurry, which is the lead paste composition used to manufacture the positive plate of the lead-acid storage battery;

[0079] A lead alloy containing 0.08%Ca, 0.15%Sn, 0.04%Al, 0.03%Bi, 0.01%Ag and the balance of Pb in weight percentage is made into a grid sample, placed in a density of 1.28g / cm 3 In sulfuric acid, at an ambient temperature of 25±2°C, at 5.0mA / cm 2 Constant current anodic polarization for 500h, and then remove oxides in hot alkali solution, calculated according to corrosion weight loss and sample surface area, the corrosion rate is 0.0867mg / (cm 2 h), 2.07mg / (cm 2 ·d), repeat the above operation and calculate, the corrosion rate is 0.0762mg / (cm 2 h), 1.831mg / (cm 2 d), showing that grids made of said lead alloys can significantly enhance their co...

Embodiment 3

[0086] 800kg of lead powder, 0.5kg of polypropylene staple fiber with a length of 1mm, 0.1kg of graphite powder, 0.4kg of PTFE emulsion and 50kg of lead-containing mixture are mixed, wherein the lead-containing mixture comprises 35kg of β-PbO 2 , 10kgα-PbO 2 And 5kg density is 1.4g / cm 3 of sulfuric acid, add 100kg water and 49kg density of 1.4g / cm 3 The sulfuric acid is stirred to obtain a slurry, which is the lead paste composition used to manufacture the positive plate of the lead-acid storage battery;

[0087] Will contain 0.08% Ca, 0.15% Sn, 0.04% Al, 0.03% Bi, 0.01% Ag, 0.01% SiO by weight percentage 2 , 0.01%Al 2 o 3 and the balance of Pb lead alloy to make the grid;

[0088] Coating the obtained lead paste composition on the prepared grid, aging, drying and chemical conversion treatment to make the positive plate of lead-acid storage battery;

[0089] Assemble the obtained positive plate, negative plate and PE separator of the lead-acid battery, pour electrolyte i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com