Micro generator

A micro-generator, pin base technology, applied in electrical components and other directions, can solve the problems of high environmental requirements, low service life, unpleasant power generation, etc., to achieve the effect of reasonable and simple structure design, reasonable structure design, convenient and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

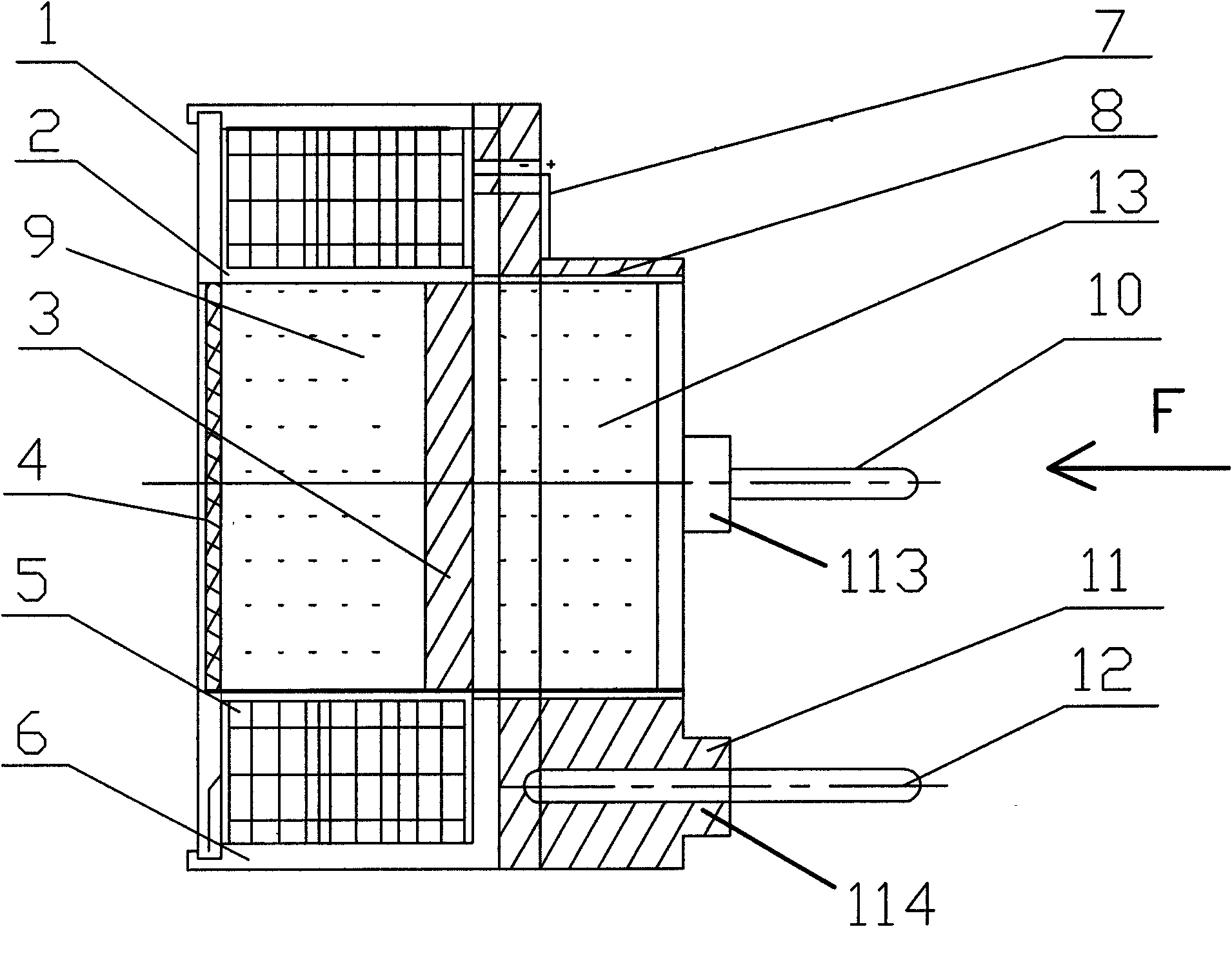

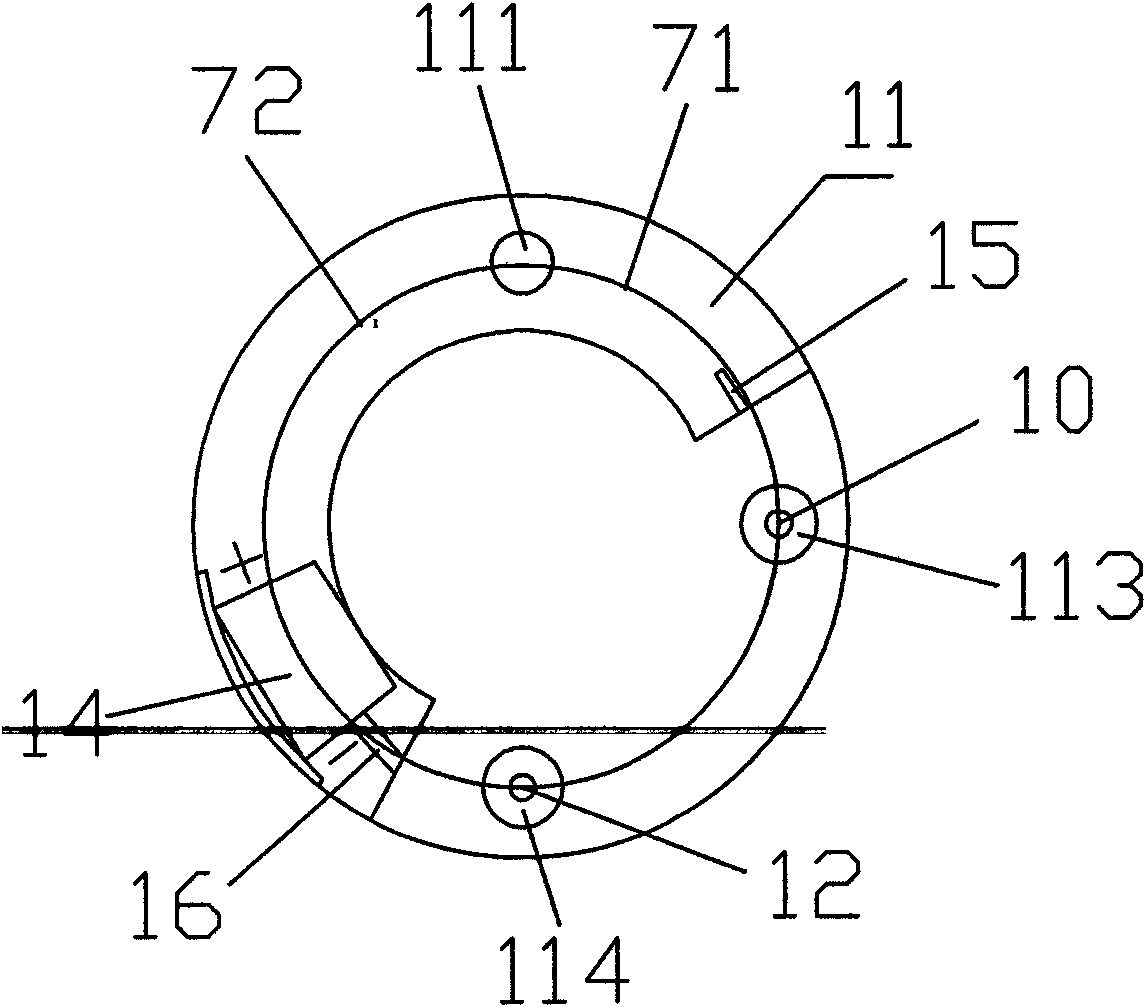

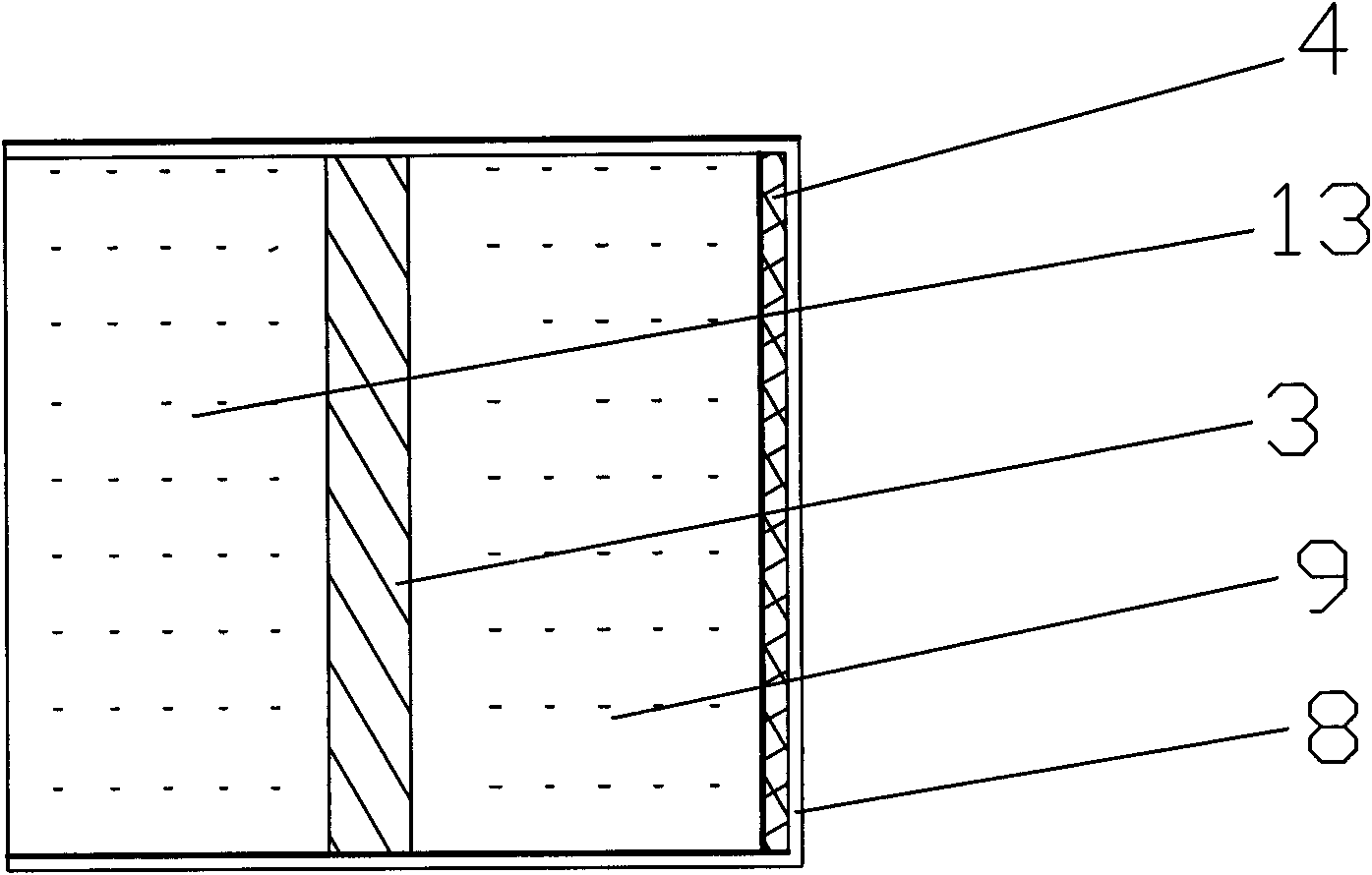

[0026] see Figure 1 to Figure 5 The structure of the embodiment of the present invention includes a housing, a coil, a bobbin 2, a magnet one 9, an iron core 3, a magnet two 13, a pole piece 4, a magnet sleeve 8, a pin base 11, an output negative pole 10 and The positive pole 12 at the output end; the casing includes a shell 6 and an end piece 1 , and the coil is formed by winding an enameled wire 5 in a coil skeleton 2 .

[0027] In this embodiment, the end piece 1 is matched with the shell 6, the pin base 11 is attached to the shell 6, one end of the magnetic steel sleeve 8 is open and the middle part is a cavity structure, and the magnetic steel sleeve 8 is located in the middle of the entire generator ; Pole shoe 4, magnet one 9, iron core 3 and magnet two 13 are installed in the magnet sleeve 8 in sequence, and the polarity of magnet one 9 is opposite to that of magnet two 13; magnet one 9 and magnet two 13 In the magnetic steel sleeve 8, the iron core 3 and the pole sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com