Solar photovoltaic-temperature difference automatic temperature control joint power generation unit

A solar photovoltaic and combined power generation technology, applied in photovoltaic power generation, generators/motors, circuits, etc., can solve problems such as reduced open circuit voltage, reduced conversion efficiency, and increased short-circuit current, so as to improve photoelectric conversion efficiency and reduce secondary The effect of secondary thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

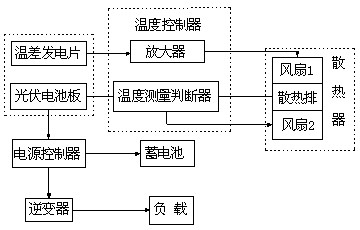

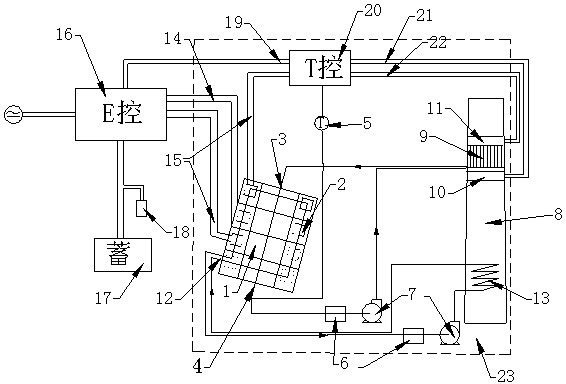

[0017] System solar photovoltaic-temperature difference self-feedback combined power generation device such as figure 1 , 2 The principle and structural block diagram shown include solar photovoltaic power generation system, thermoelectric power generation system, cooling system, power control system and temperature control system. The heat generated during the power generation of the photovoltaic power generation system is used as the energy source. When the cooling water passes through the back channel, the heat is taken away to the chimney radiator and dissipated. The temperature difference module 2 is evenly placed at a suitable position between the back of the photovoltaic cell and the water cooling head, and part of the thermal energy is converted into electrical energy. The power generated by the two sets of temperature difference modules 2 is taken out and supplied to the strong exhaust fan 11 after being boosted and stabilized by the temperature controller 20 to enhance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com