Method for preparing energy gas and achieving chromium slag harmlessness through biomass

A biomass and energy gas technology, applied in the gasification process, the production of combustible gas, recycling technology, etc., can solve the problem of affecting the flow performance and space size of pyrolysis equipment, the ineffective utilization of biomass tar, and the difficulty of recycling chromium residues. and other problems, to achieve the effect of reducing secondary thermal pollution, improving the quality of fuel products, and avoiding the control of air pressure by the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

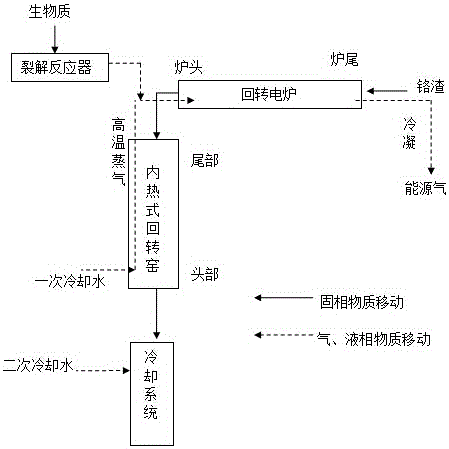

[0026] 1. After the chromium slag is ground to <2mm, it is transported to the tail of the rotary electric furnace through the screw feeder, and finally transported to the furnace head. Heating by an electric furnace keeps the temperature of the chromium slag at the furnace head stable at 800-1000°C. After being discharged from the furnace head, the chromium slag enters the internal heating rotary kiln head, and then is transported to the kiln tail;

[0027] 2. The biomass is cracked at 500-600°C, and the cracked gas is then sent to the head of the rotary electric furnace, where it is mixed with high-temperature steam and chromium slag outside the furnace head; the mixed gas of high-temperature steam and biomass cracking gas is mixed with chromium slag in the rotary electric furnace Reverse operation, catalytic cracking reaction occurs during the process, after being discharged from the tail of the rotary electric furnace, high-quality energy gas is obtained through condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com