A method for synchronously treating chromium slag and chlorine-free plastics

A synchronous treatment, chlorine plastic technology, applied in the removal of solid waste, products, educts, etc., can solve the problems of uncontinuous utilization, expensive catalyst, equipment blockage, etc., to achieve harmlessness, improve fuel product quality, save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

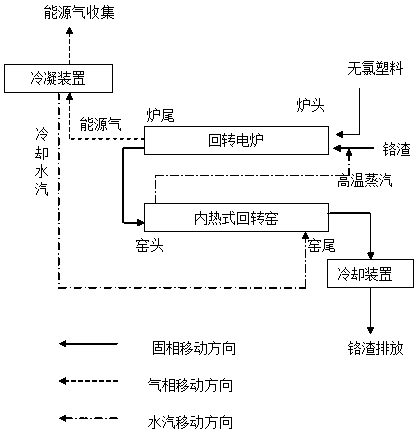

Image

Examples

example 2

[0028] 1. Grind the chromium slag to <2mm, mix it with high-temperature steam and chlorine-free plastic, and then transport it to the head of the rotary electric furnace, and then to the tail of the furnace. Heating by an electric furnace, keeping the temperature of the electric furnace stable at 1000°C, and keeping the material in the electric furnace for 30 minutes. After the furnace tail is discharged, the gas phase energy product is sent to the condensing device, and the chromium slag enters the kiln head of the internal heating rotary kiln, and then is sent to the kiln tail of the internal heating rotary kiln;

[0029] 2. After the energy gas enters the condensing device, it flows in the opposite direction with the cooling water and undergoes indirect heat exchange for dehydration treatment, and then is collected into the gas collection tank for subsequent use;

[0030] 3. Part of the cooling water vapor after heat exchange is sent to the end of the internal heating rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com