Method for preparing biopesticide through liquid fermentation

A biopesticide and liquid fermentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, botany equipment and methods, etc., can solve the problems of short conidia storage period, lack of sporulation conditions, and short shelf life of products and other issues, to achieve the effect of strong resistance to external adverse environments, low cost, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

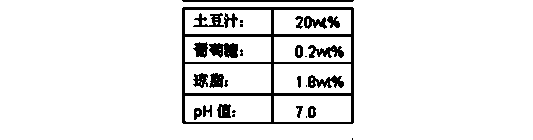

[0073] Trichoderma harzianum was inoculated in an eggplant-shaped culture bottle filled with potato juice medium under aseptic conditions, plugged with a sterile cotton plug, and then put the eggplant-shaped culture bottle in a constant temperature incubator and cultivated at 25-28 °C 3-5 days. The main components of potato juice medium are as follows:

[0074]

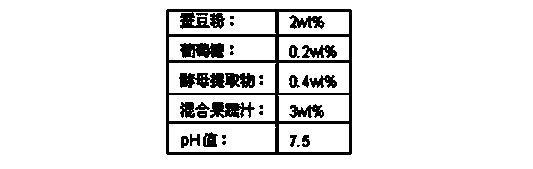

[0075] The cultured Trichoderma harzianum was transferred to a 1L shaker flask containing 300ml of fungal culture solution under aseptic conditions. Obtain the conidia liquid. The main components of the nutrient solution are as follows:

[0076]

[0077] Prepare the same culture solution, put the culture solution into the fermenter, add defoamer, and then carry out high-temperature (121°C) high-pressure (15 pounds) sterilization for 25 minutes. The fermenter was maintained at positive pressure, and the air flow was reduced when it was cooled to 28°C, and the obtained conidia liquid was poured into the flame p...

Embodiment 2

[0080] Referring to the method described in Example 1, the conidia liquid (ie first-order seeds) was obtained.

[0081] Prepare the same culture solution, put 65L of culture solution into a 100L fermenter, add 100ml of defoamer, and then carry out high-temperature (121°C) high-pressure (15 lb) sterilization for 25 minutes. The fermenter was maintained at positive pressure, and the air flow was reduced when it was cooled to 28°C, and the obtained conidia liquid was poured into the flame port. Ferment for 3 days at 28±0.5°C, tank pressure 0.4~0.5kg, air flow 1800~2100L / h, rotation speed 185rpm to obtain secondary seeds.

[0082] Prepare the same culture solution, put 1200L of culture solution into a 2-ton fermenter, add 1000ml of defoamer, and then perform in-situ high-temperature (121°C) high-pressure (15 lb) sterilization for 25 minutes. Keep the positive pressure in the fermenter, reduce the air flow when it cools down to 28°C, keep the pressure in the 2-ton fermenter at 0.2...

Embodiment 3

[0085] Referring to the method described in Example 1, the pure strains of Trichoderma pseudoconii (CGMCC3.3002), Trichoderma harzianum (CGMCC No.1780) and Trichoderma viride were inoculated in potato juice medium solanum under aseptic conditions. Put the eggplant-shaped culture bottle into a constant temperature incubator and incubate for 3-5 days at 25-28°C.

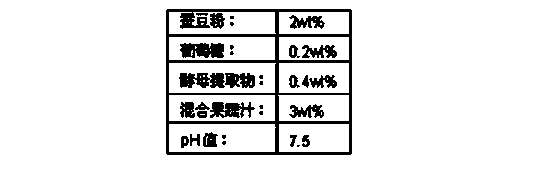

[0086] At the same time, Trichoderma harzianum, Trichoderma viridans and Trichoderma pseudoconii were inoculated uniformly around the potato juice medium culture dish by point-connection method, and three to five days were observed after culturing at 25-28°C for 3-5 days. Compatibility of different strains. After testing, the compatibility and growth speed of the three strains can meet the production needs. The main components of the potato juice culture medium are as follows:

[0087]

[0088] The three different Trichoderma strains prepared from the eggplant-shaped culture flask were transferred to a 1L shake fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com