Preparation method for polyurethane synthetic leather with water repellent performance

A technology of synthetic leather and polyurethane, which is applied to the surface coating liquid device, surface pretreatment, textiles and papermaking, etc. It can solve the problems of weak water repellency and achieve good dispersion and easy dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

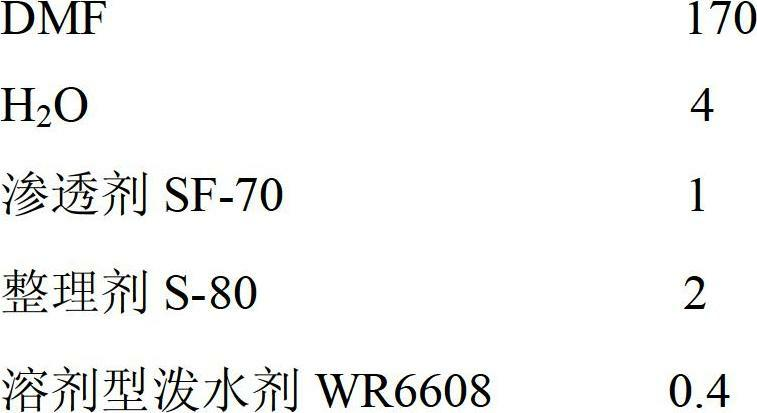

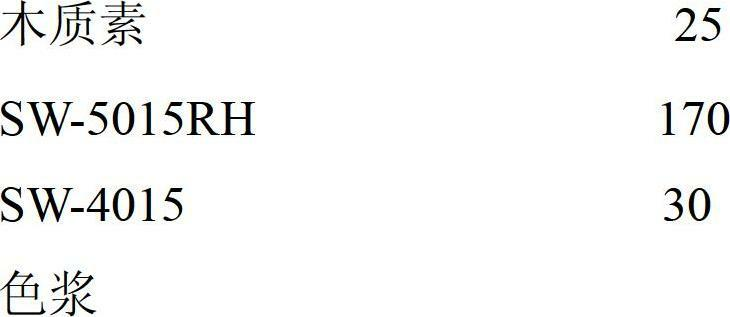

[0025] 2. Preparation of wet-process synthetic leather crust

[0026] Apply the wet-process polyurethane slurry prepared in step 1 to the base fabric and place it in a coagulation tank to solidify, then wash with water to obtain a wet-process synthetic leather semi-finished product, drain the wet-process synthetic leather semi-finished product and place it in a water-based water-repellent solution Moderate wetting, and finally segmental drying (drying to moisture content 0) after shaping, the wet synthetic leather crust is obtained; the segmental drying is mainly to avoid the problem of different moisture content in different parts of the crust, so that the obtained wet synthetic leather Different parts of the synthetic leather crust are dried to the same degree; in this embodiment, drying is divided into five stages, and the drying temperatures are respectively set at 140°C, 160°C, 160°C, 140°C and 80°C.

[0027] The water-based water-repellent solution consists of 100 parts ...

Embodiment 2

[0033] The preparation method of this example is the same as that of Example 1, except that the water-based water-repellent solution in step 2 consists of 100 parts by mass of deionized water, 25 parts of water-based defoamer SD-2025, and 100 parts of water-based water-repellent AD-HCS518.

[0034] The water repellency test results of the polyurethane synthetic leather prepared in this example are as follows: 3*20cm (weft*warp) crust leather sample is soaked in 25°C clear water solution for 8 hours, and the rise of the liquid level is ≤0.5cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com