Method for designing electric pump hydraulic energy system in cabin

A system design, hydraulic energy technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve the problems of long working cycle, large design, and large amount of modification, and achieve the goal of improving output power and improving work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

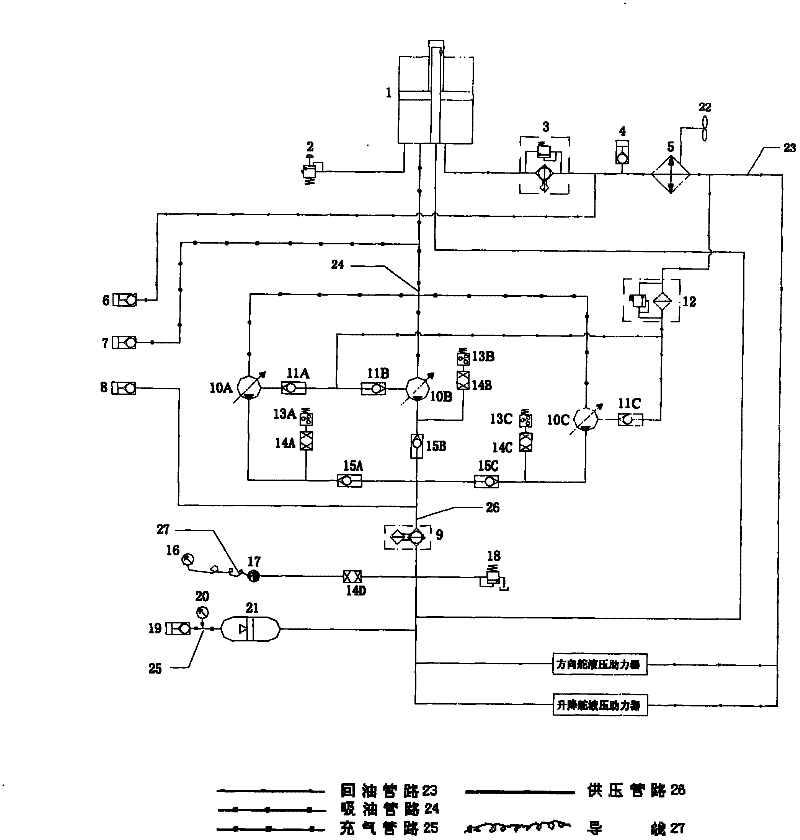

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Design and install a high-strength electric pump hydraulic energy system equipment rack in the aircraft cargo compartment, and centrally arrange the accessories of the electric pump hydraulic energy system on the equipment rack, including system oil tank 1, air release valve 2, and system oil return Filter 3, sampling valve 4, hydraulic radiator 5, fuel tank valve 6, oil suction valve 7, booster valve 8, shell oil return filter 9, AC electric pump 10A, 10B, 10C, one-way valve 11A, 11B, 11C , system high-pressure oil filter 12, pressure relay 13A, 13B, 13C, buffer valve 14A, 14B, 14C, 14D, one-way valve 15A, 15B, 15C, pressure gauge indicator 16, pressure gauge sensor 17, safety valve 18, inflation Valve 19, miniature pressure gauge 20, pressure accumulator 21, fan 22, oil return pipeline 23, oil suction pipeline 24, inflation pipeline 25, pressure supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com