Oil injection device and oil injection method

An oil injection device and oil cylinder technology, which is applied in the direction of lubricating oil control valve, lubricating pump, engine components, etc., can solve the problems of slow oil injection speed and low efficiency, and achieve the effect of improving oil injection speed and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

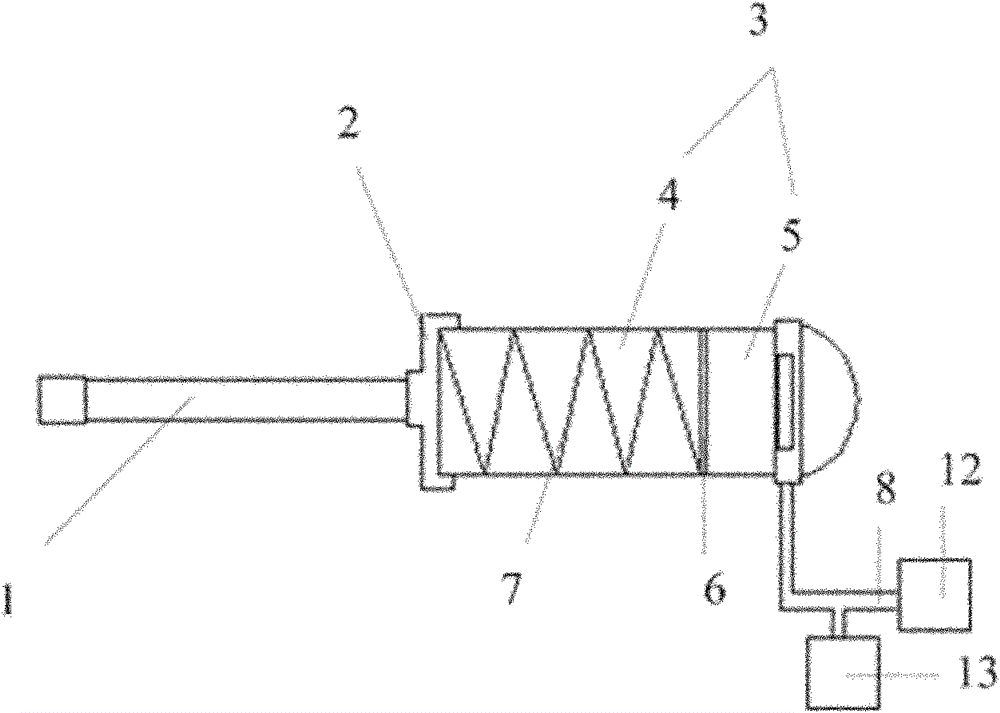

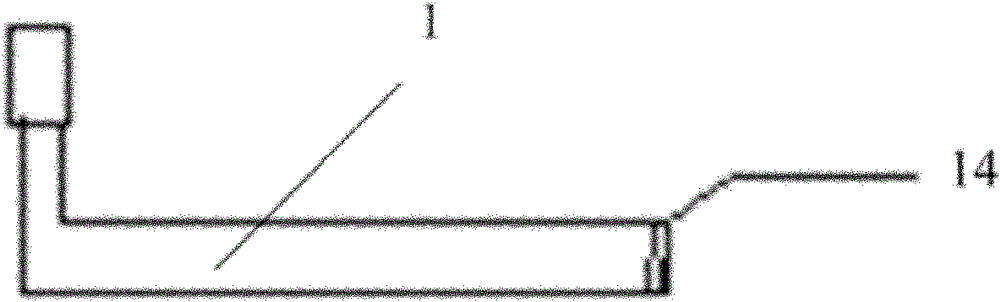

[0043] figure 1 It is a schematic structural diagram of the oil injection device provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the shape of the gun nozzle in the oil injection device provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides an oil injection device, such as figure 1 As shown, it includes a gun nozzle 1, an end cover 2 and an oil cylinder 3, wherein a piston 6 is arranged in the oil cylinder 3, and the oil cylinder 3 is divided into two parts: a grease chamber 4 and a pressure chamber 5 by the piston 6; the pressure chamber 5 is provided with a liquid inlet , used to communicate with the pressure liquid power source 12 through the introduction pipeline 8, and push the piston 6 to move toward the grease chamber 4 by filling the pressure chamber 5 with pressure liquid; the grease chamber 4 is provided with a spring 7, and the first end of the spring 7 Butt against the end cover 2,...

Embodiment 2

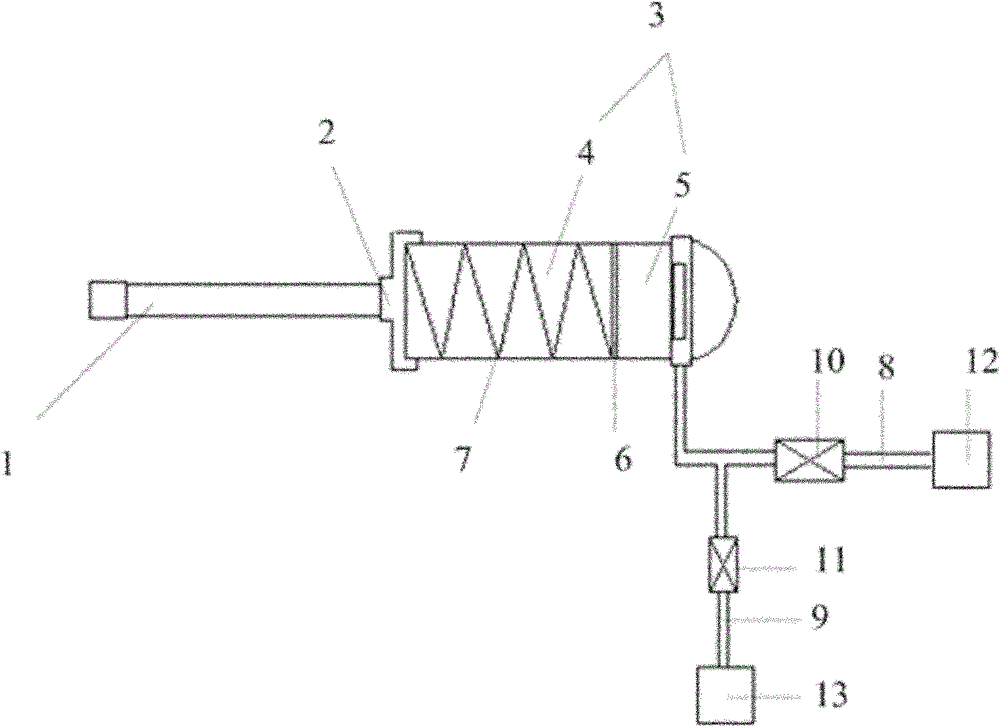

[0049] image 3 The structure diagram of the oil injection device provided by Embodiment 2 of the present invention. Embodiment 2 of the present invention provides an oil injection device. The difference from Embodiment 1 is that the pressure chamber 5 is further provided with a liquid outlet, and the liquid outlet is passed through the outlet pipeline. 9 is connected to the outside world 13, such as image 3 As shown, it is used to discharge the pressure liquid in the pressure chamber 5. The liquid inlet and the liquid outlet can be two independent openings, preferably as in this embodiment image 3 As shown, the liquid inlet and the liquid outlet are the same opening, and the inlet pipeline 8 and the outlet pipeline 9 communicate with the opening through a common pipeline.

[0050] Further, a pressure inlet valve 10 is provided in the introduction pipeline 8 connected to the liquid inlet to switch the conduction and disconnection of the introduction pipeline 8 when the pre...

Embodiment 3

[0054] Figure 4The flow chart of the oil injection method provided by the third embodiment of the present invention, the third embodiment of the present invention provides an oil injection method, using the oil injection device provided by any embodiment of the present invention, please refer to figure 1 and Figure 4 , the oil injection device includes a gun nozzle 1, an end cover 2, and an oil cylinder 3, wherein a piston 6 is arranged in the oil cylinder 3, and the oil cylinder 3 is divided into two parts: a grease chamber 4 and a pressure chamber 5 by the piston 6; the pressure chamber 5 is provided with a liquid The inlet is used to communicate with the pressure liquid power source 12 through the introduction pipeline 8, and to push the piston 6 to move toward the grease chamber 4 by filling the pressure chamber 5 with pressure liquid; the grease chamber 4 is provided with a spring 7, and the first spring 7 One end is against the end cover 2, and the second end is again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com