Nanometer environmentally-friendly inflaming retarding cotton yarn filling rope and manufacturing process thereof

A technology of flame-retardant cotton and filling rope, which is applied in the field of flame-retardant materials to achieve the effect of improving flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The invention comprises a polyester-cotton layer or an all-cotton layer or an all-polyester layer in the inner layer, and a flame-retardant layer is arranged outside the inner layer.

[0017] The flame retardant layer is made of nano-scale Mg(OH) 2 , Al(OH) 3 Compatible with acrylic acid emulsion.

[0018] The weight ratio of each material in the flame retardant layer is: nano-scale Mg(OH) 2 60%: Nanoscale Al(OH) 3 25%: smoke suppressant 5%: acrylic acid emulsion 10% mixed.

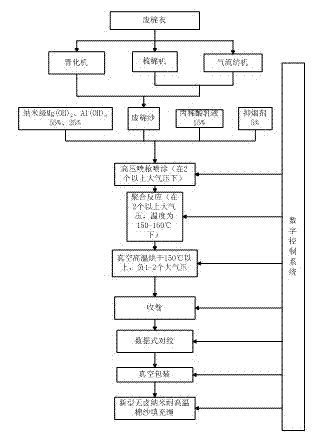

[0019] The present invention carries out according to the following processing steps:

[0020] 1) Comb the material through high-speed carding machine, open-end spinning machine, and greening machine, and comb it into a base fabric that meets the requirements;

[0021] 2) Use a high-pressure spray gun to spray nano-sized Mg(OH) 2 : Nanoscale Al(OH) 3 : Smoke suppressant: a flame retardant liquid composed of acrylic acid emulsion, which is sprayed on the base fabric with a high-pressure spray...

Embodiment 2

[0026] The invention comprises a polyester-cotton layer or an all-cotton layer or an all-polyester layer in the inner layer, and a flame-retardant layer is arranged outside the inner layer.

[0027] The flame retardant layer is made of nano-scale Mg(OH) 2 , Al(OH) 3 Compatible with acrylic acid emulsion.

[0028] The weight ratio of each material in the flame retardant layer is: nano-scale Mg(OH) 2 50%: Nanoscale Al(OH) 3 28%: smoke suppressant 6%: acrylic acid emulsion 16% mixed.

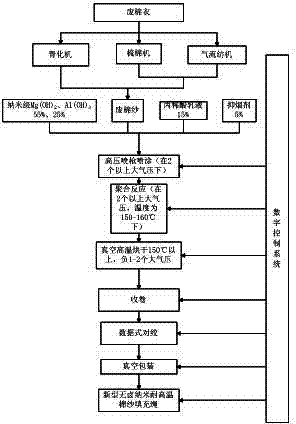

[0029] The present invention carries out according to the following processing steps:

[0030] 1) Comb the material through high-speed carding machine, open-end spinning machine, and greening machine, and comb it into a base fabric that meets the requirements;

[0031] 2) Use a high-pressure spray gun to spray nano-sized Mg(OH) 2 : Nanoscale Al(OH) 3 : Smoke suppressant: a flame retardant liquid composed of acrylic acid emulsion, which is sprayed on the base fabric with a high-pressure spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com