Color filtering sheet and manufacturing method thereof as well as liquid crystal display

A color filter, color technology, applied in the direction of filter, instrument, optics, etc., can solve the problem of black matrix light leakage between pixels and other problems, and achieve the effect of avoiding light leakage, low cost, and reducing the step difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

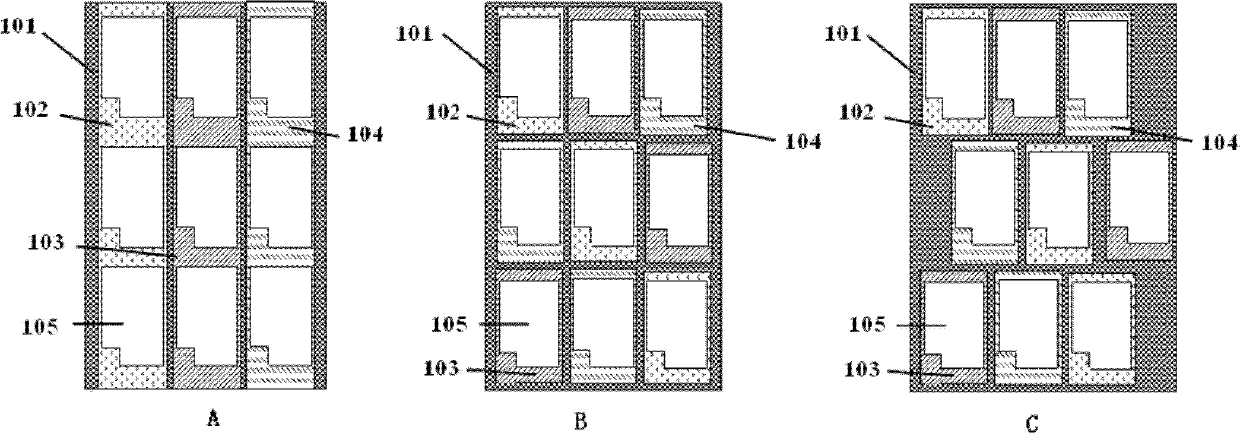

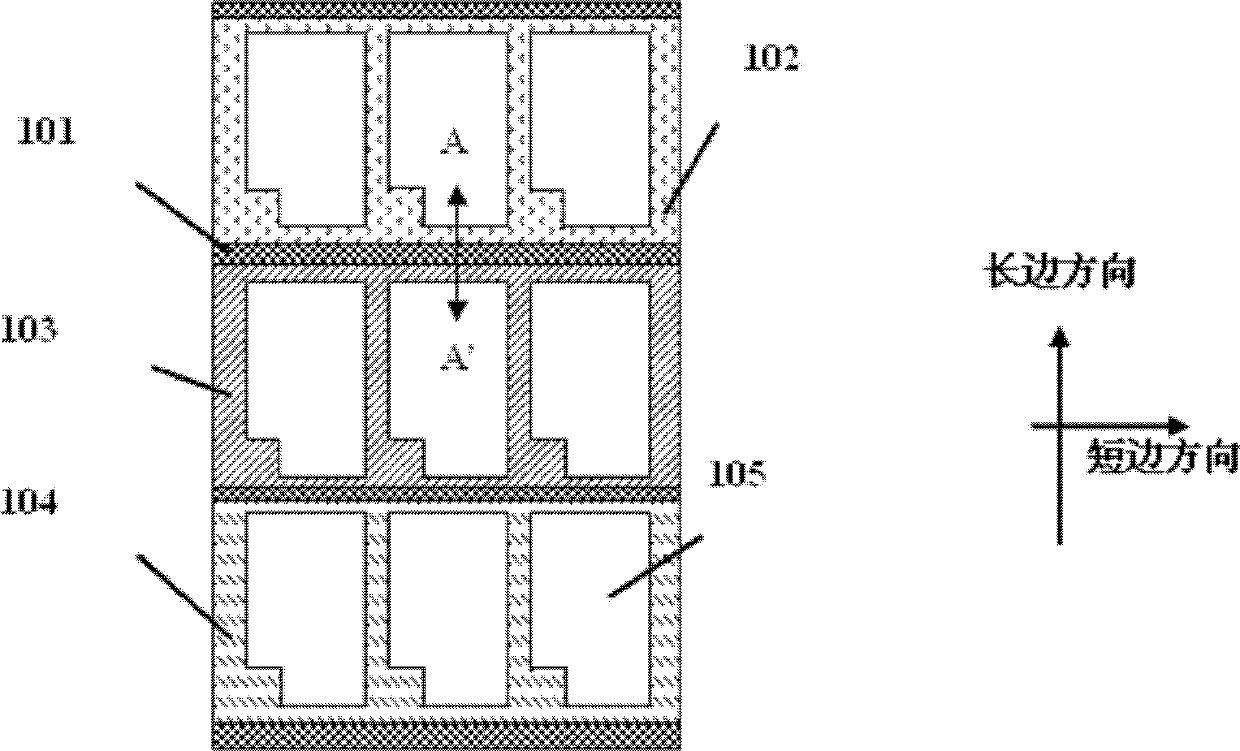

[0033] In this embodiment, the color filter includes a substrate, a black matrix 101, color filter film layers of different colors, a common electrode layer and other optional layers, the black matrix 101 is arranged on the substrate and forms a grid shape, and the substrate A sub-pixel opening area 105 is formed on the upper part that is not covered by the black matrix 101. The sub-pixel opening area 105 has a long side and a short side. The sub-pixel opening areas 105 are arranged in rows along the short side direction. Color filter layers of the same color are arranged in the pixel opening area 105 to form a color filter layer row, and the color filter layer rows of different colors are arranged circularly in sequence. In this embodiment, each color filter film layer in the color filter film layer row is an integrated structure that is connected to each other and is convenient for manufacture.

[0034] Wherein, the color filter layers of different colors include a red color...

Embodiment 2

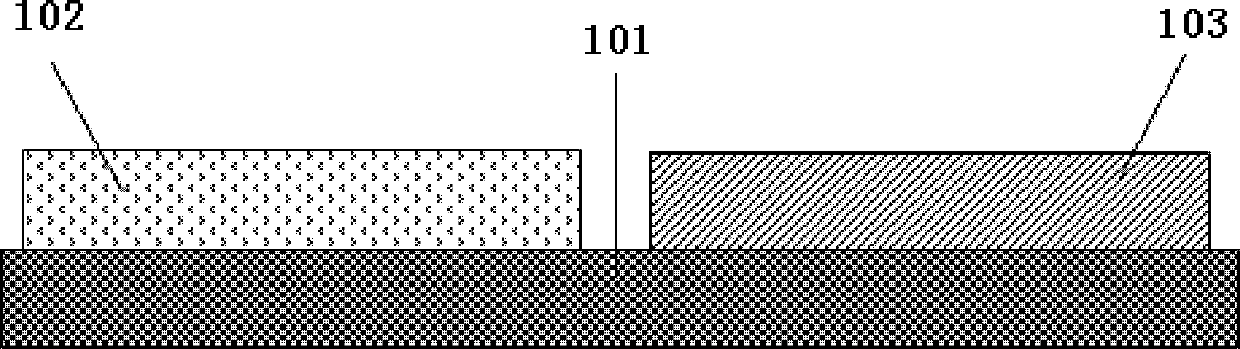

[0044] The difference between the color filter in this embodiment and Embodiment 1 is that two adjacent rows of color filter layers of different colors overlap and distribute on the black matrix. Figure 4 shows that this example corresponds to figure 2 A schematic diagram of the cut plane of the color filter layer AA', wherein the red color filter layer rows formed by the arrangement of the red color filter layers 102 and the green color filter layer rows formed by the arrangement of the green color filter layers 103 are in the black matrix 101 The upper phase overlaps.

[0045] Other structures and manufacturing methods of the color filter in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0046] A liquid crystal display, comprising a color filter and an array substrate, the array substrate includes a plurality of parallel grid lines and data lines perpendicularly intersecting the grid lines, and the color filter adopts the color fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com