Clamp driving mechanism special for ornament machining equipment

A technology of processing equipment and special fixtures, applied in clothing, applications, jewelry, etc., can solve problems such as easy vibration, gap value accumulation, and single jewelry variety, so as to avoid product processing size errors, improve jewelry quality, and reduce noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

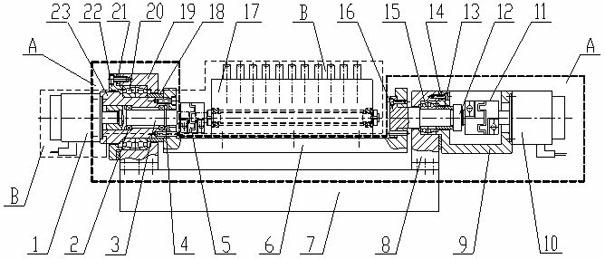

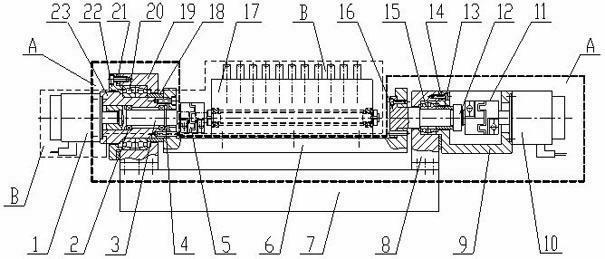

[0010] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 Shown: a special fixture driving mechanism for jewelry processing equipment, including a rotary unit A, a jewelry facet unit B and a device body 7; the left and right ends of the rotary unit A are respectively fixed on the device body 7 by screws and conical pins, and the jewelry The left end of the facet unit B is supported inside the left end of the rotary unit A, and the right end is fixed in the middle of the rotary unit.

[0011] Slewing unit A includes fixture base 6, right bearing seat 8, motor support 9, brake motor 10, right coupling 11, lock nut 12, right spacer 13, right adjusting pad 14, right angular contact ball bearing assembly 15. Connecting shaft 16, left spacer 18, left bearing seat 19, left angular contact ball bearing assembly 20, left adjusting pad 21, end cover 22, support shaft 23; left bearing seat 19 and right bearing seat 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com