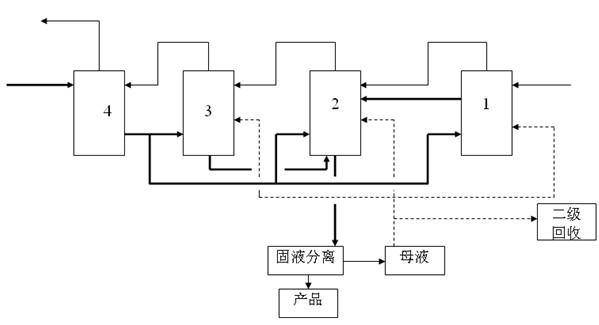

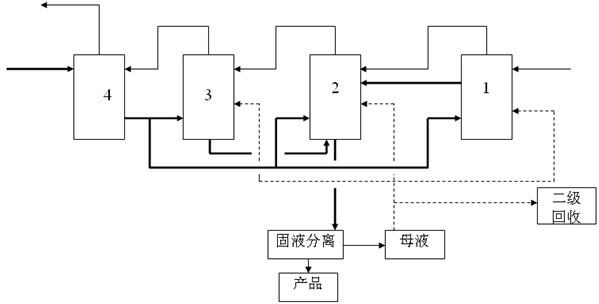

Four-effect cross-flow evaporation system and process

An evaporation system and efficient evaporation technology, applied in the four-effect cross-flow evaporation system and process field, can solve the problems of unfavorable separation operation, methionine deterioration, accumulation and blockage of pipes and separators, etc., to achieve control of material concentration, high heat transfer efficiency, The effect of preventing the material concentration from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Pass 17kg / h of sodium sulfate solution containing methionine (wherein the content of methionine is 2.44%, the content of sodium sulfate is 18.89%) into the four-effect cross-flow evaporation system of the present invention, and carry out heating, evaporation and crystallization according to the above-mentioned four-effect cross-flow evaporation process, and the evaporation heat source Using 0.7MPa saturated steam 4kg / h, the evaporation time is 1.1 hours.

[0031] The material from the second effect evaporator 2 was analyzed, and the sodium sulfate content was 31.2%, the methionine content was 5.2%, the water content was 52.3%, and the rest were impurities. It was observed that most of the crystals were formed in the second effect evaporator 2; Analyze the mother liquor obtained by solid-liquid separation, wherein the content of sodium sulfate is 22.4%, the content of methionine is 5.1%, the water content is 61.2%, and the rest are impurities; the material from the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com