Method and device for vulcanizing inner mold and outer mold of tire through direct voltage electromagnetic heating

An electromagnetic heating device and technology of inner and outer molds, which are applied in the field of tire vulcanization, can solve problems affecting product qualification rate, uneven tire quality distribution, and steam heat dissipation, so as to shorten tire vulcanization time, improve tire vulcanization quality, and electromagnetic heating high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

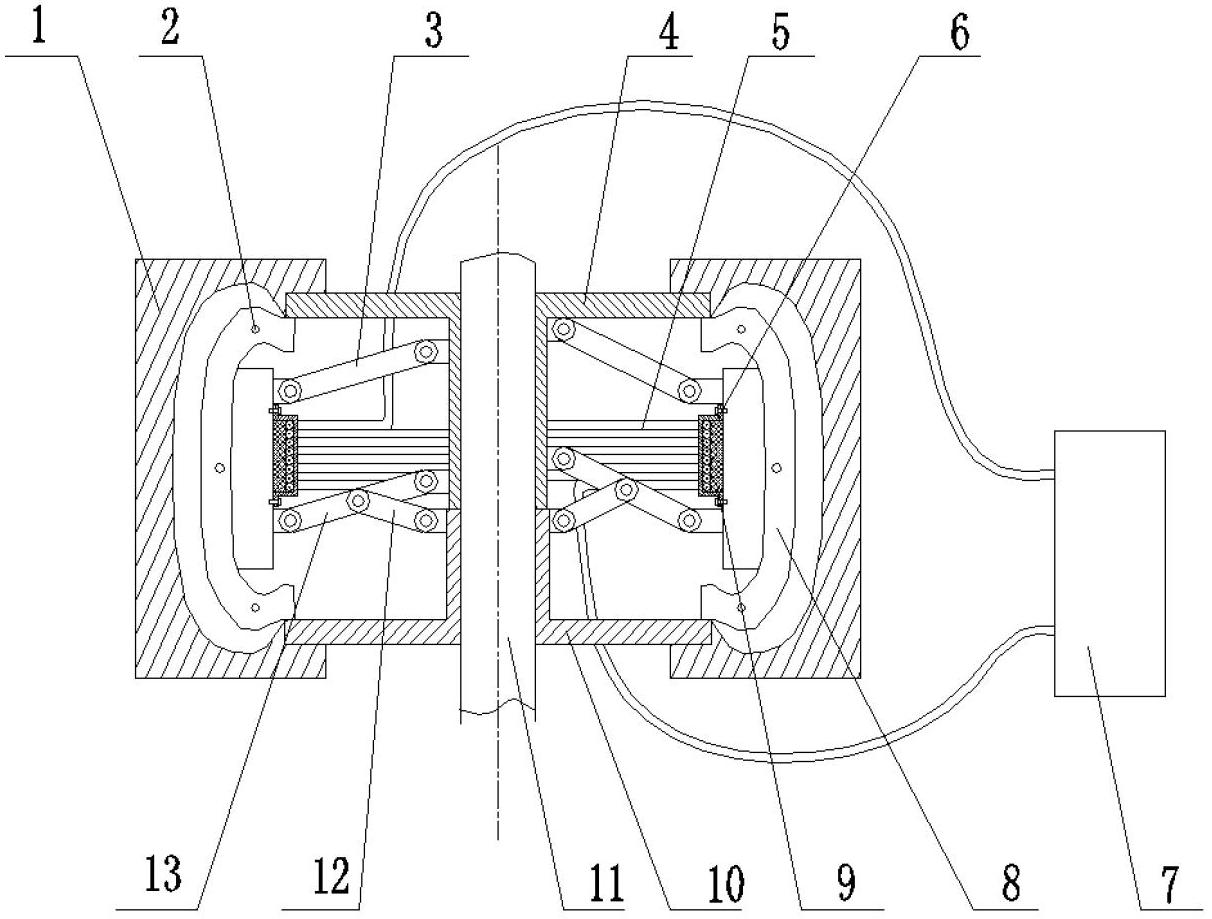

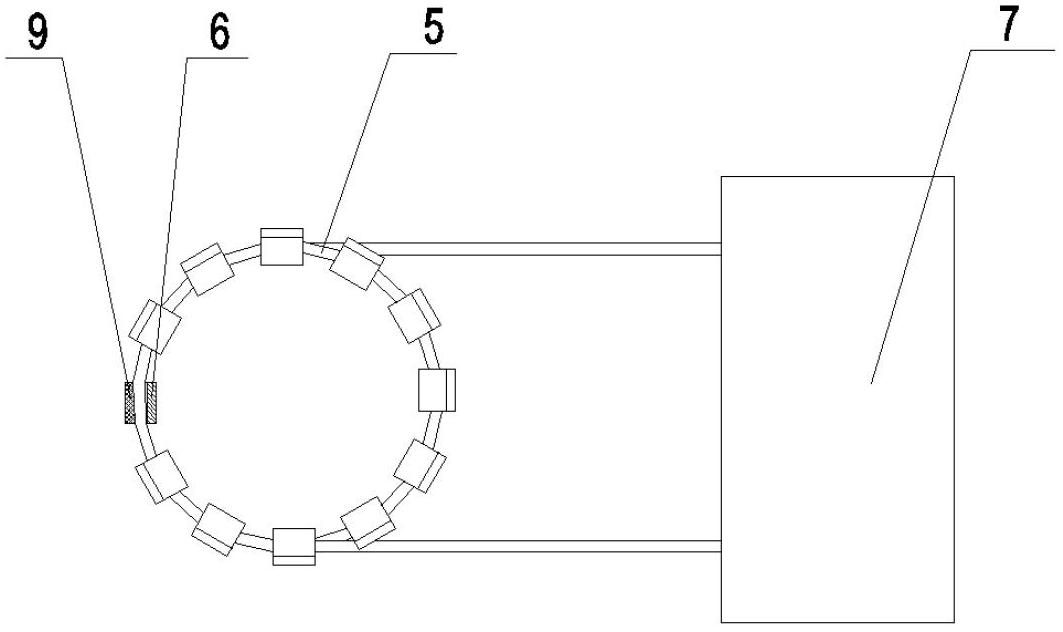

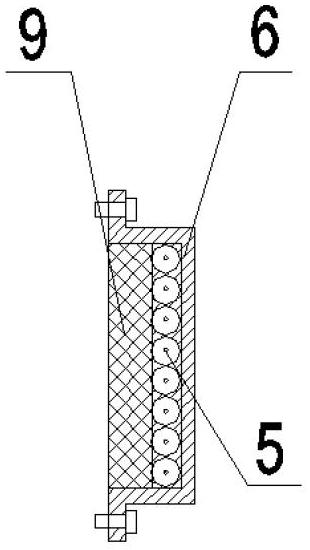

[0019] The present invention is a tire inner and outer mold direct pressure electromagnetic heating vulcanization device, such as figure 1 As shown, the vulcanization bladder on the center mechanism of the existing tire shaping vulcanizer is replaced with a building drum structure. The building drum structure includes an expansion and contraction mechanism and a power mechanism. The power mechanism includes a piston rod 11, an upper tray 4, a lower tray 10, and an upper tray. 4 and the lower tray 10 are set on the piston rod 11, wherein the upper tray 4 is fixedly connected with the piston rod 11, and the expansion and contraction mechanism includes six sets of wide tile expansion and contraction mechanisms and narrow tile expansion and contraction mechanisms distributed at intervals, each set of wide tile The expansion and contraction mechanism and the narrow tile expansion and contraction mechanism are respectively composed of long drum tiles / narrow drum tiles and two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com