Un-stacking and stacking machine

A stacker and stacking technology, applied in the field of storage machinery, can solve the problems of high production cost, low level of automation, waste of resources, etc., and achieve the effect of improving the utilization rate of storage capacity, improving the level of automation, and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

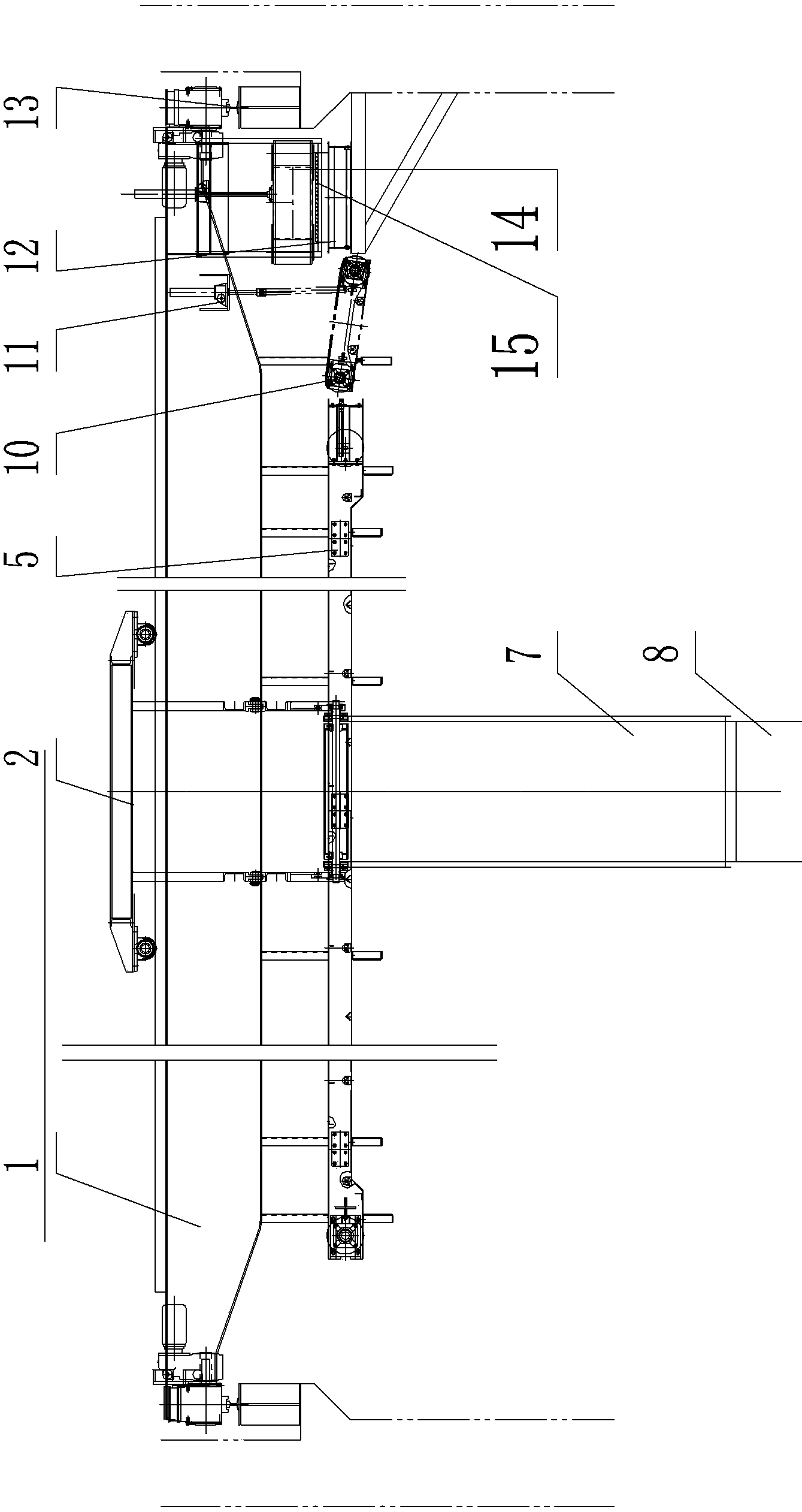

[0031] Example: see Figure 1-4 , Figure 9-Figure 13 , a kind of unstacking palletizer in the figure, comprises the big crane that is installed in the storeroom, the conveyor in the storehouse that is parallel to the track at the lower part of the track of the big crane, it is characterized in that: the described big crane is provided with track, the There is a small crane on the track of the big crane, the lower part of the big crane is equipped with a horizontal conveyor, the upper part of the small crane is a small crane frame, and the lower part is an inclined conveyor mounting frame, and an inclined conveyor is installed under the inclined conveyor mounting frame , at the cross adjacent position of the horizontal conveyor and the conveyor in the warehouse, there is a bag-reversing device A and a transitional turning conveyor A. One end of the transitional turning conveyor A is connected to the frame of the large crane through a hinge, and the other end is passed Lifting...

Embodiment 2

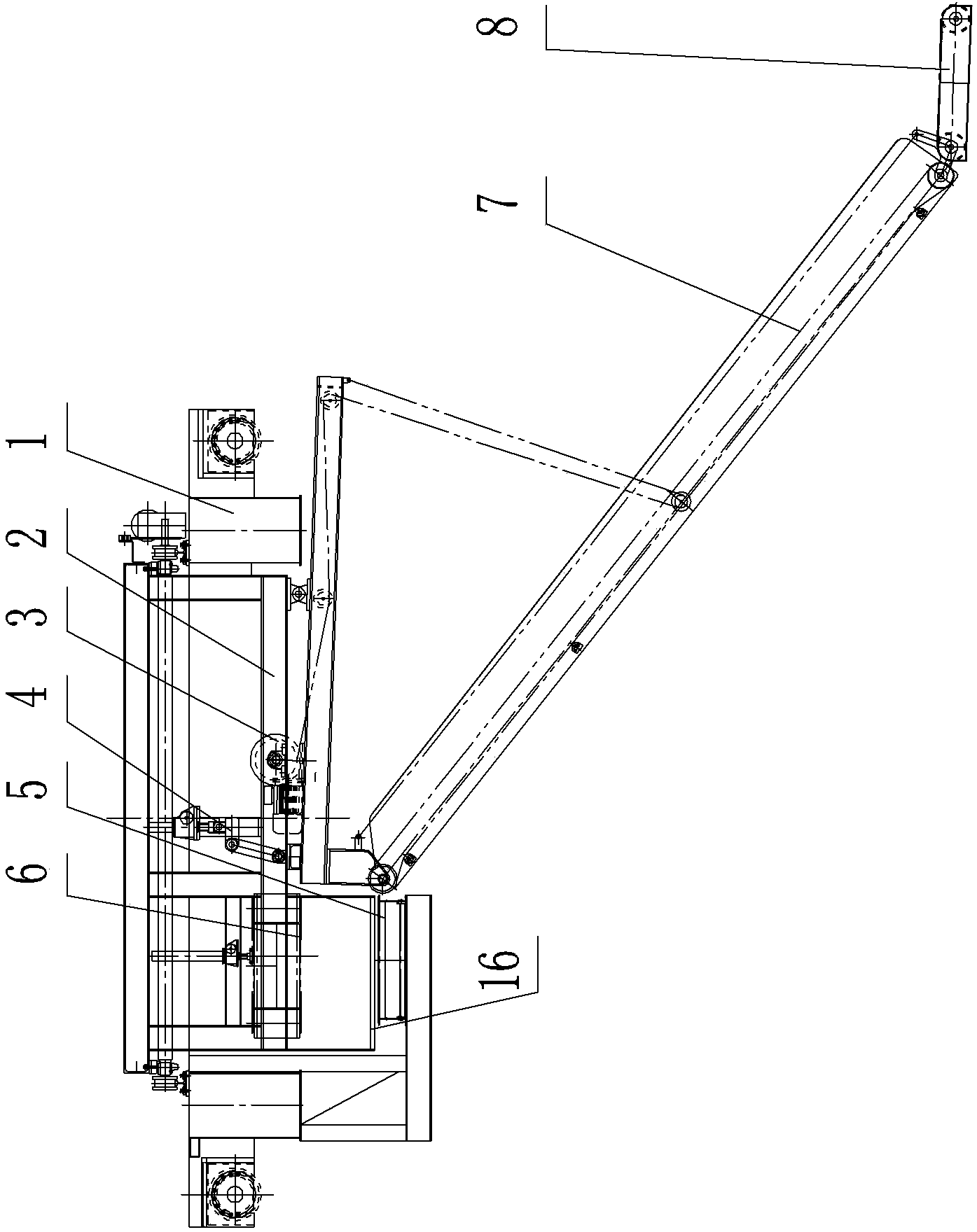

[0043] Embodiment two: see Figure 1-2 , Figure 5-6 , Figure 9-Figure 13 , a kind of unstacking palletizer in the figure, comprises the big crane that is installed in the storeroom, the conveyor in the storehouse that is parallel to the track at the lower part of the track of the big crane, it is characterized in that: the described big crane is provided with track, the There is a small crane on the track of the big crane, the lower part of the big crane is equipped with a horizontal conveyor, the upper part of the small crane is a small crane frame, and the lower part is an inclined conveyor mounting frame, and an inclined conveyor is installed under the inclined conveyor mounting frame , at the cross adjacent position of the horizontal conveyor and the conveyor in the warehouse, there is a bag-reversing device A and a transitional turning conveyor A. One end of the transitional turning conveyor A is connected to the frame of the large crane through a hinge, and the other ...

Embodiment 3

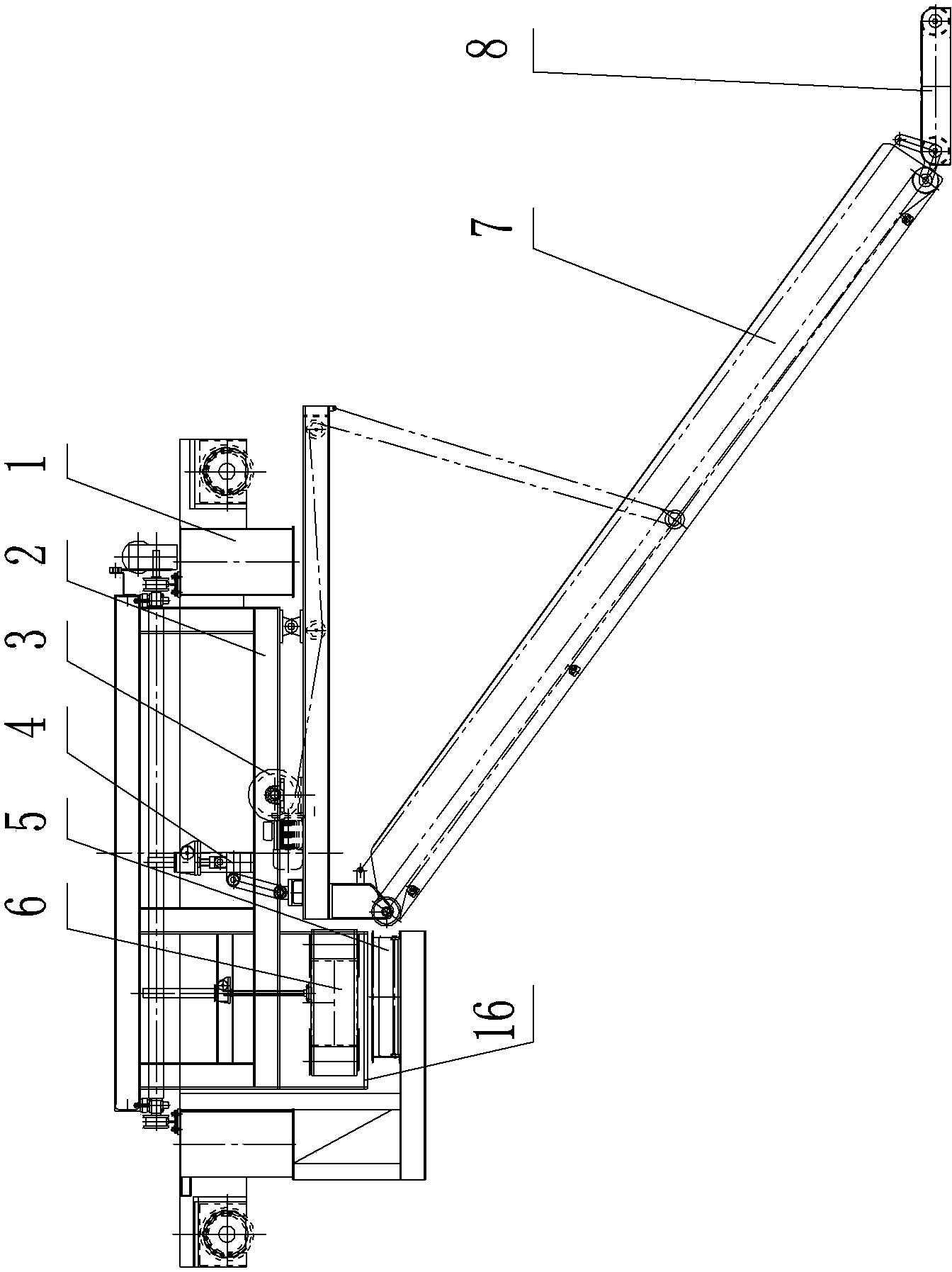

[0054] Embodiment three: see Figure 1-2 , Figure 7-8 , Figure 9-Figure 13 , a kind of unstacking palletizer in the figure, comprises the big crane that is installed in the storeroom, the conveyor in the storehouse that is parallel to the track at the lower part of the track of the big crane, it is characterized in that: the described big crane is provided with track, the There is a small crane on the track of the big crane, the lower part of the big crane is equipped with a horizontal conveyor, the upper part of the small crane is a small crane frame, and the lower part is an inclined conveyor mounting frame, and an inclined conveyor is installed under the inclined conveyor mounting frame , at the cross adjacent position of the horizontal conveyor and the conveyor in the warehouse, there is a bag-reversing device A and a transitional turning conveyor A. One end of the transitional turning conveyor A is connected to the frame of the large crane through a hinge, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com