Device and technique for cyclically producing ammonium chloride from combined-soda-process semi-mother liquor II

A technology of semi-mother liquor and ammonium chloride, which is applied in the direction of ammonium halide, can solve the problems of affecting production and easy scabbing of heat exchangers, and achieve the effects of reducing production and operation costs, benefiting the production of combined alkali, and reducing the concentration of combined ammonium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

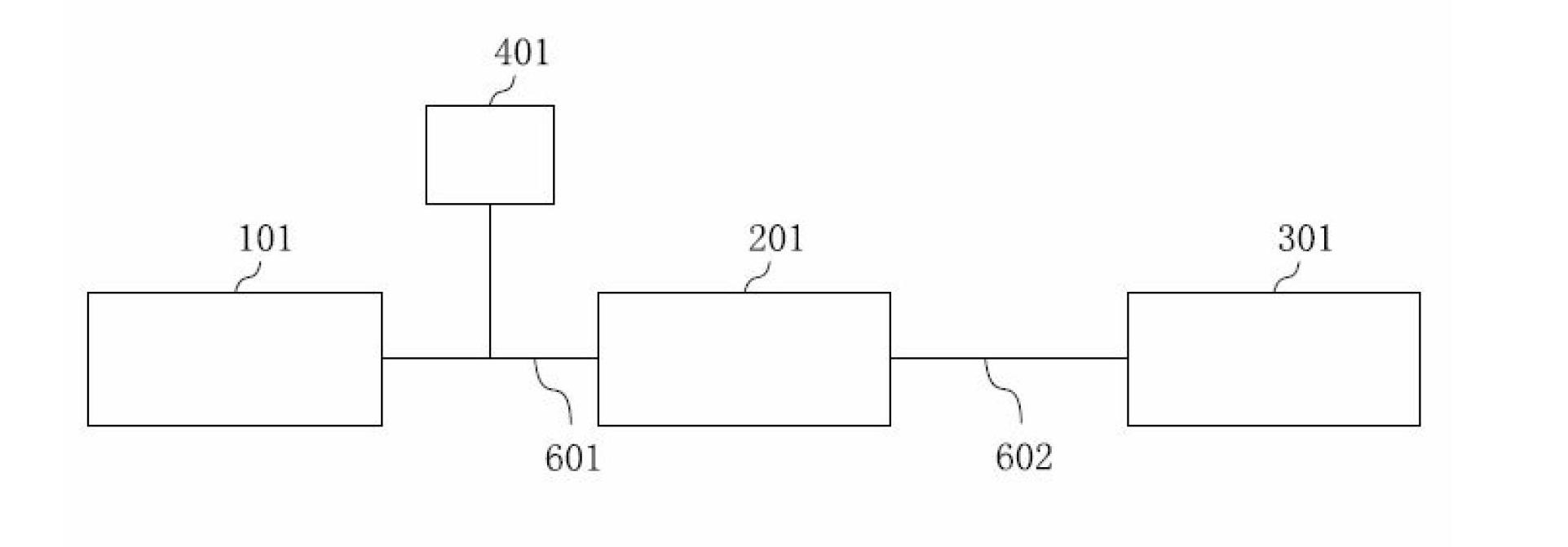

[0038] figure 1 It is a schematic diagram of a device for producing ammonium chloride by circulating alkali and semi-mother liquor II. Such as figure 1 As shown, the outlet valve at the bottom of the semi-mother liquor II barrel 101 is connected with the semi-mother liquor II pump 201 through a pipeline 601, and the semi-mother liquor II pump 201 outlet valve is connected with the ammonia mother liquor I barrel 301 inlet valve through a pipeline 602, and is connected between the semi-mother liquor II barrel 101 and the semi-mother liquor II barrel 101 and A meter 401 is arranged between the semi-mother liquor II pumps 201 .

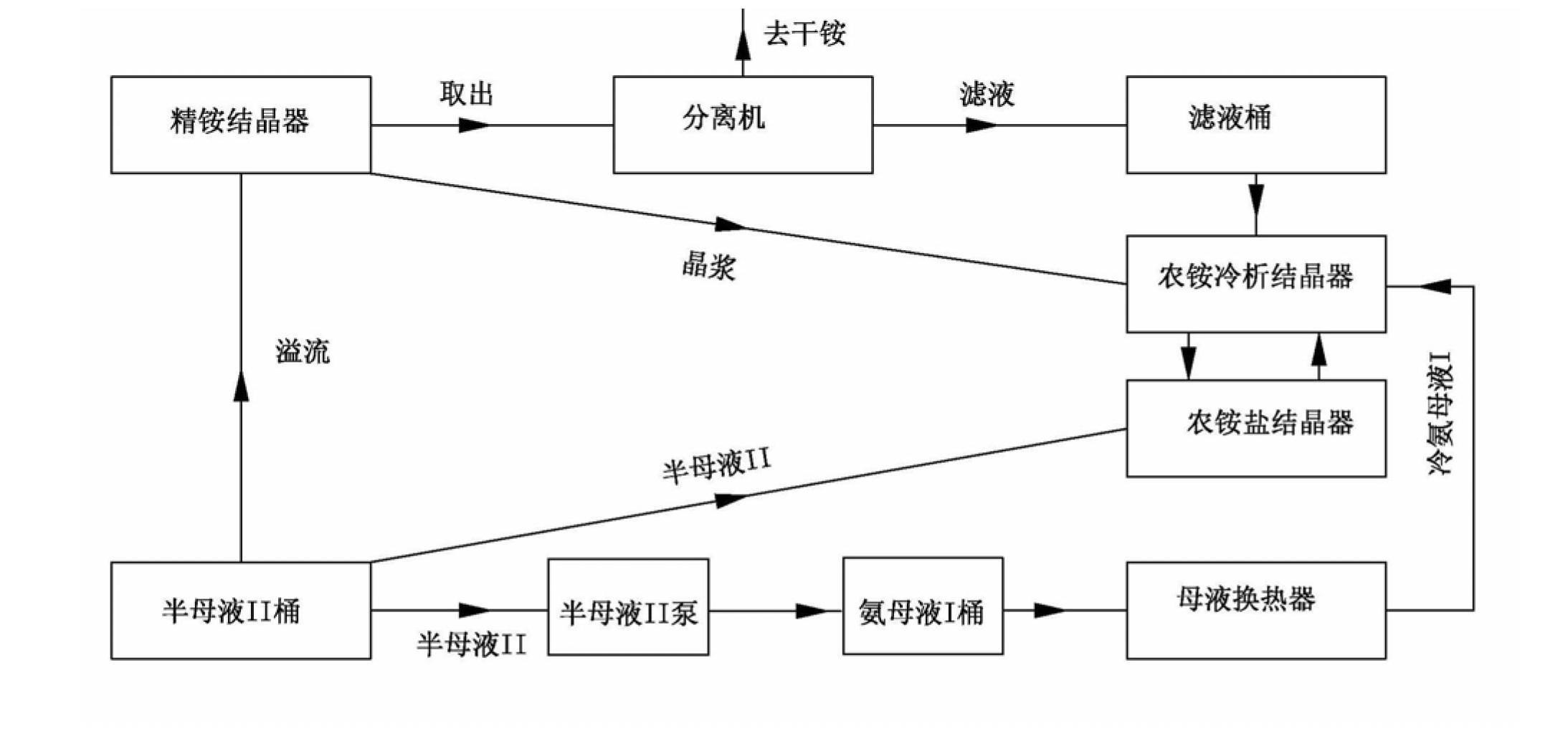

[0039] figure 2 It is a flow chart of the production process of ammonium chloride by circulating alkali and semi-mother liquor II.

[0040] A combined soda semi-mother liquor II cycle production process for ammonium chloride, taking 600,000 tons of combined soda system as an example,

[0041] In order to achieve the goal of no scarring in the heat ex...

Embodiment 2

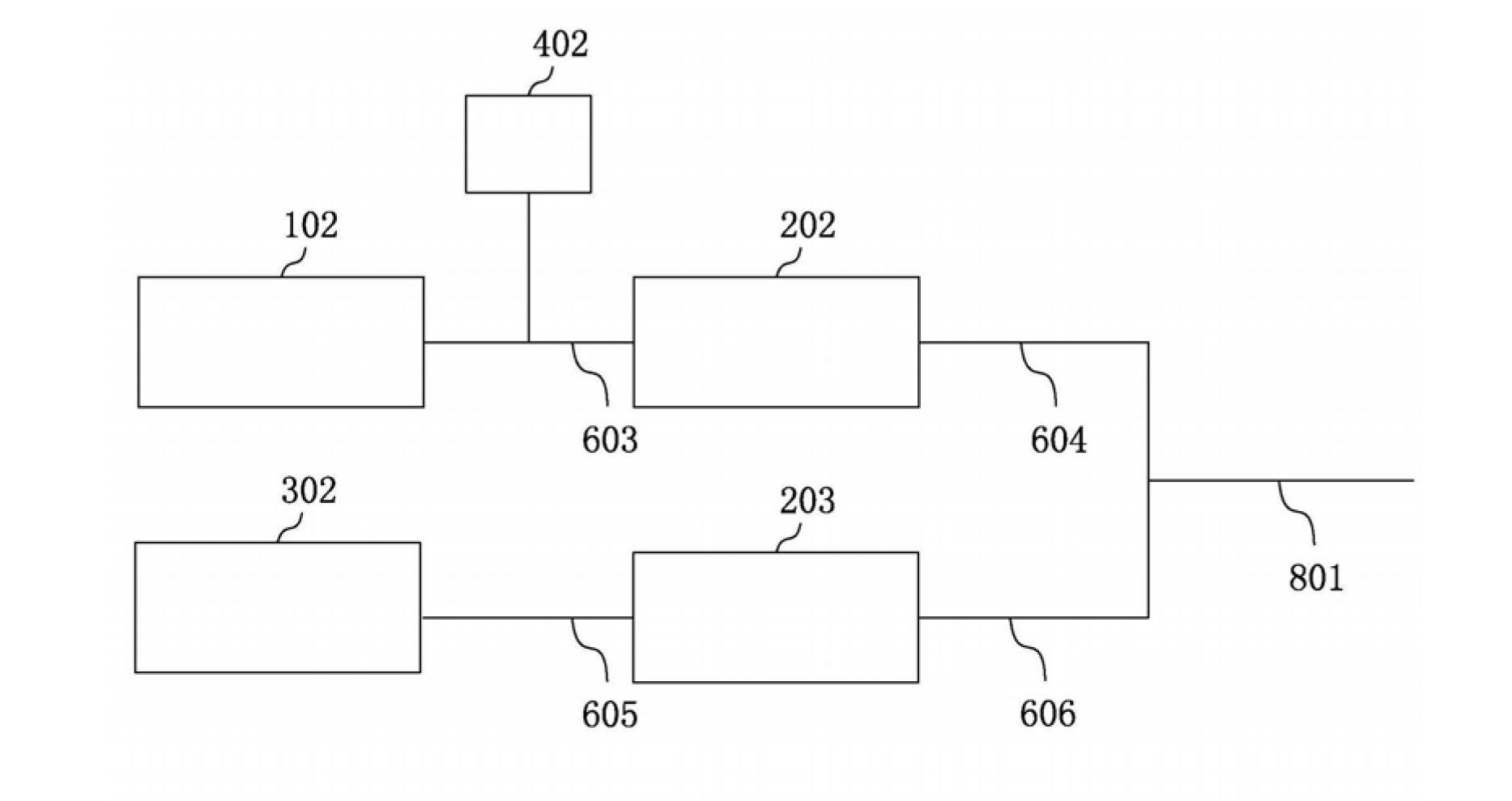

[0049] image 3 It is another preferred combined alkali semi-mother liquor II cycle production ammonium chloride device schematic diagram. As shown in the figure, the outlet valve at the bottom of the semi-mother liquor II barrel 102 is connected to the semi-mother liquor II pump 202 through a pipeline 603, and the semi-mother liquor II pump 202 outlet valve communicates with the mixing pipeline 801 through a pipeline 604, and is connected between the semi-mother liquor II barrel 102 and the semi-mother liquor Meter 402 is set between II pumps 202; the outlet valve at the bottom of ammonia mother liquid I barrel 302 is connected with ammonia mother liquid I pump 203 through pipeline 605, and the outlet valve of ammonia mother liquid I pump 203 is communicated with mixing pipeline 801 through pipeline 606.

[0050] A combined soda semi-mother liquor II cycle production process for ammonium chloride, taking 600,000 tons of combined soda system as an example,

[0051] In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com