Cracking preventing porcelain glaze of enamel and preparation of cracking preventing porcelain glaze

A technology of blasting porcelain and enamel, which is applied in the field of anti-explosion enamel and preparation of enamel, can solve the problems of scale explosion of enamel products, and achieve the effect of improving elasticity and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific experimental examples.

[0027] The equipment used in the embodiment of the present invention is conventional equipment, and the purity of the raw materials used in the production of anti-explosion enamel meets the requirements of industrial grade, wherein NiO is required to be green nickel oxide, and the purity is Ni≥75%.

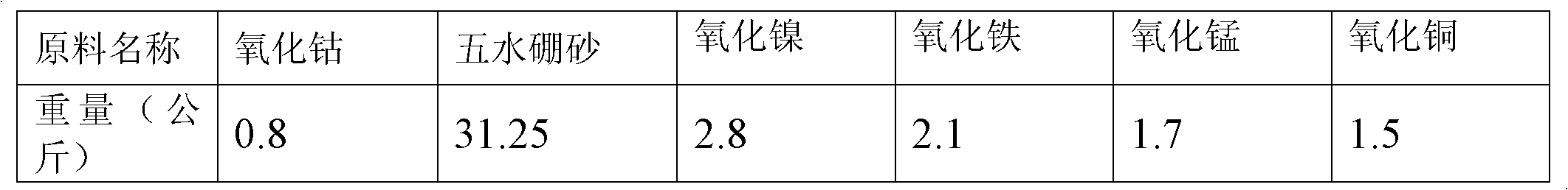

[0028] First, according to the component formula shown in Table 1, these several raw materials are pre-mixed and ball-milled dry-milled, and the mixing uniformity is ≥99.5%.

[0029] Table 1

[0030]

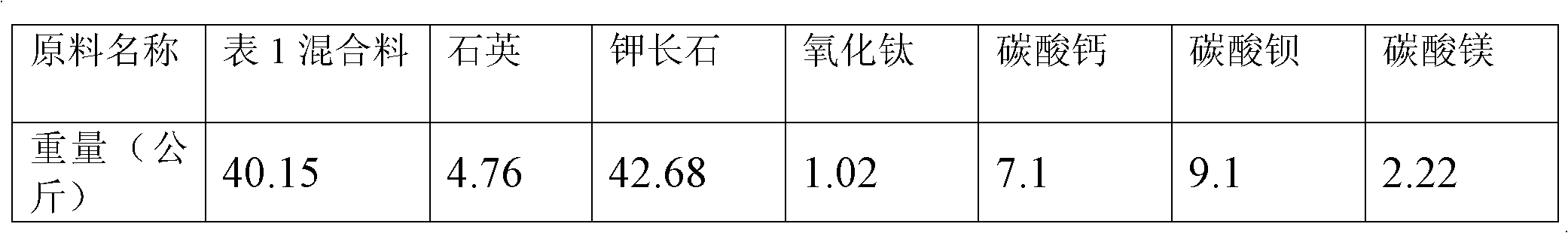

[0031] Then mix the components according to the parts by weight shown in Table 2, and the uniformity of mixing is more than or equal to 98%.

[0032] Table 2

[0033]

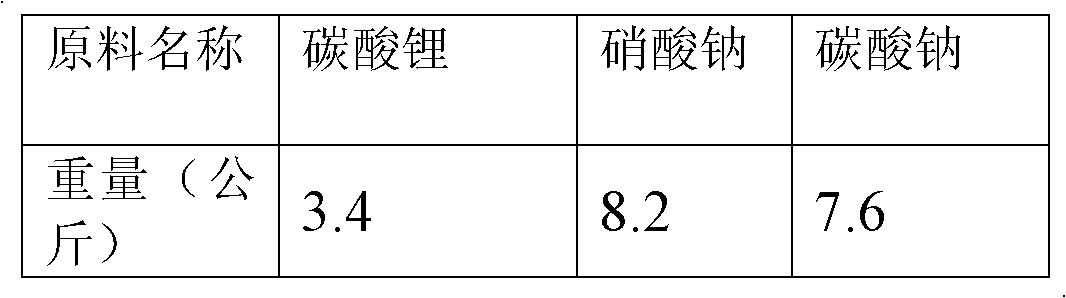

[0034] Continued Table 2

[0035]

[0036] In table 2, the composition content (mass percentage) of potassium feldspar is: 8.2% K 2 O, 2.2% Na 2 O, 15% Al 2 o 3 , 73.5% SiO 2 , P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com