Method for preparing anhydrous oxalic acid from oxalic acid and production device using method

A technology of anhydrous oxalic acid and production equipment, which is applied in the separation/purification of carboxylic acid compounds, drying gas arrangement, lighting and heating equipment, etc. Precise and scientific, process-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for preparing anhydrous oxalic acid with oxalic acid in the present invention comprises the following steps: put oxalic acid into a closed container and heat it, and when the temperature rises to 50-60°C, control the temperature for 55-65 minutes, then raise the temperature again, and wait for the temperature to rise to 101-105 ℃, then control the temperature for 10 to 15 minutes to obtain anhydrous oxalic acid.

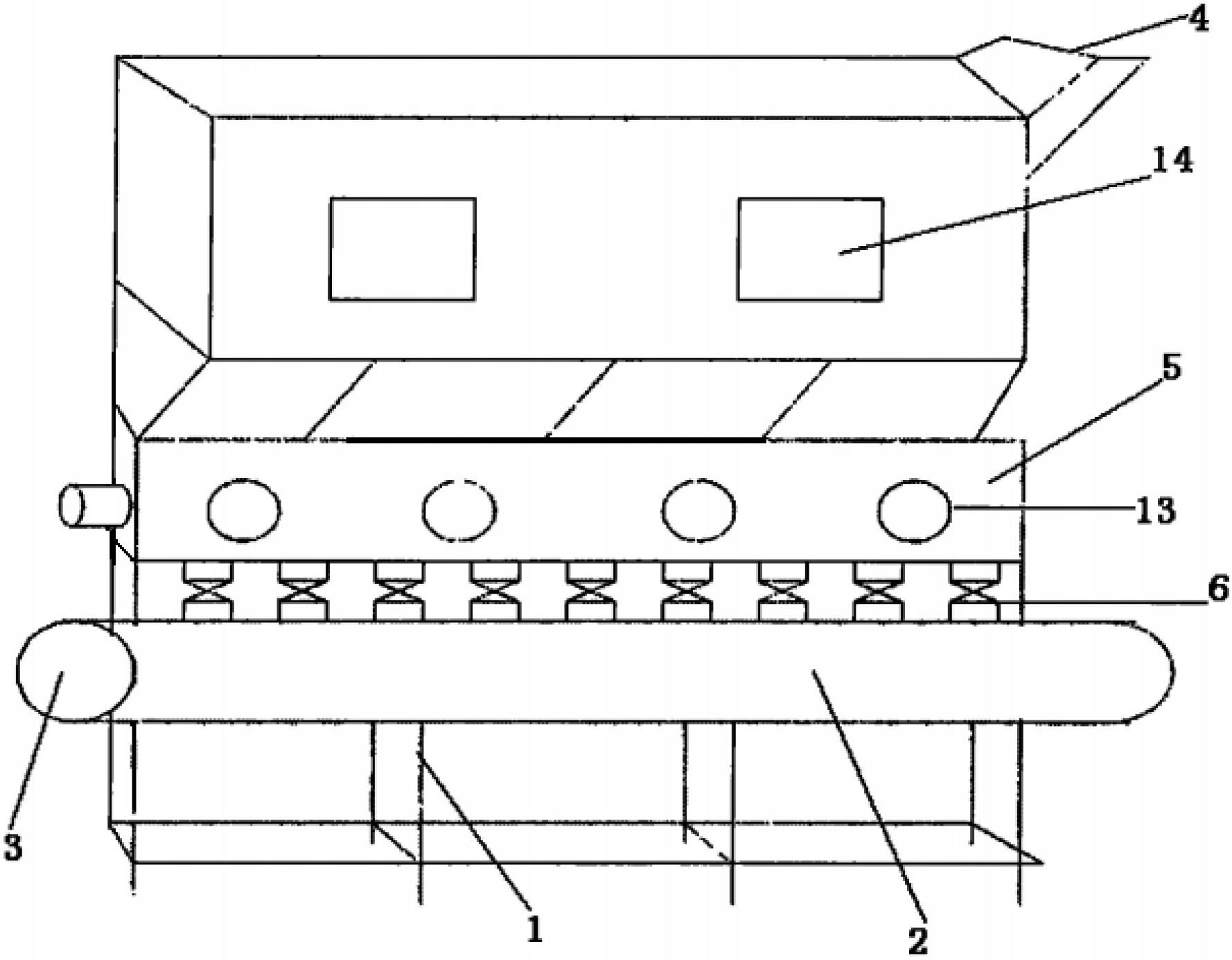

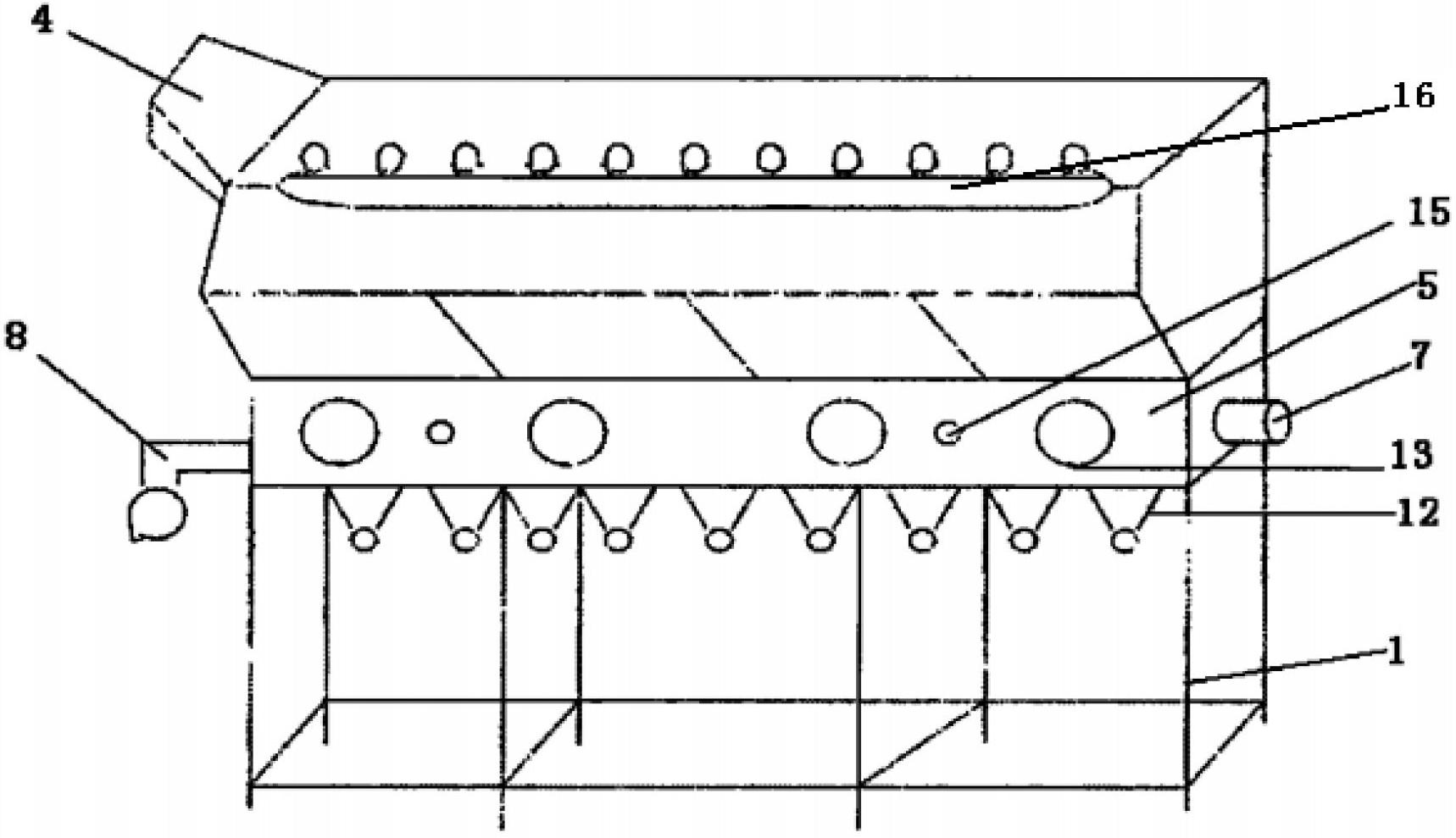

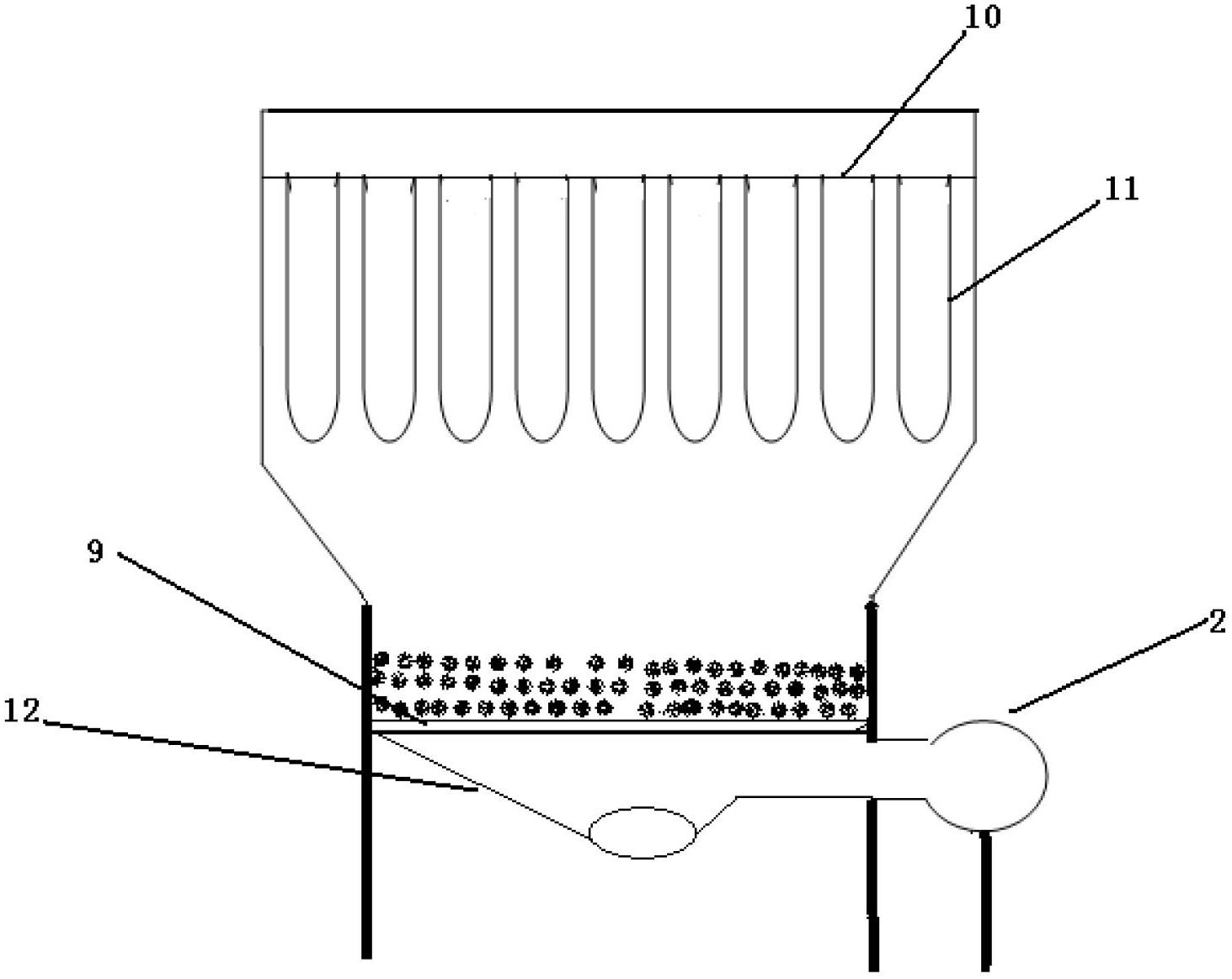

[0015] The production equipment used to realize the method is as figure 1 , 2 , 3, it includes a support 1, which is fixedly connected to the hot air chamber 2 above the support. One end of the hot air chamber 2 has a hot air inlet 3, and the upper end of the hot air chamber 2 is fixedly connected with a drying chamber 5, and the hot air chamber and the drying chamber are connected by several pipelines with air volume regulating valves 6. The both sides of described drying chamber 5 have feed inlet 7, discharge port 8 respectively, have viewing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com