Production device and preparation process for anhydrous oxalic acid

A production device, a technology for anhydrous oxalic acid, which is applied in heating devices, separation/purification of carboxylic acid compounds, and dry gas layout, etc., can solve the problems of high energy consumption, small output, low yield, etc., and achieve process environmental protection and drying. Precise and scientific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

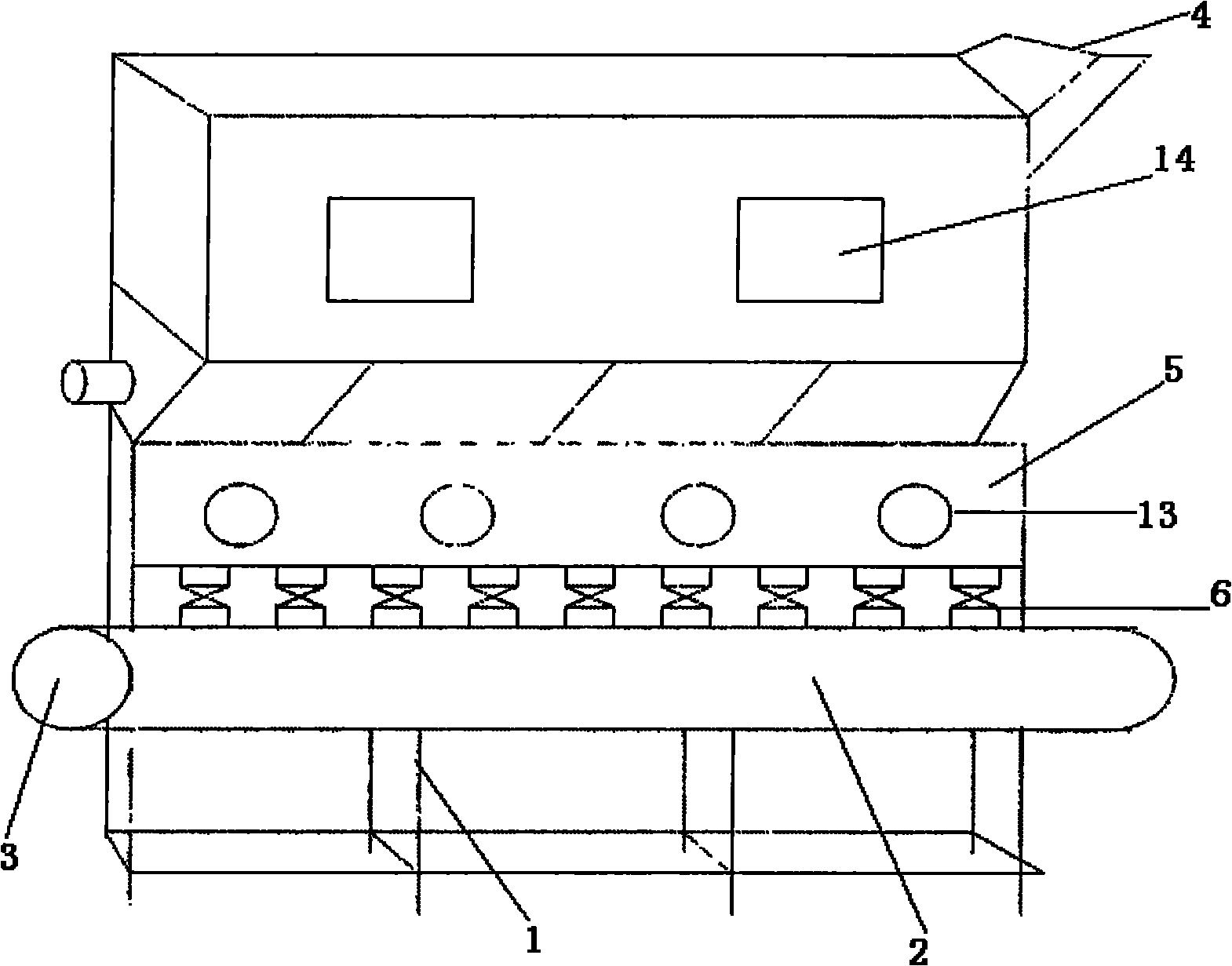

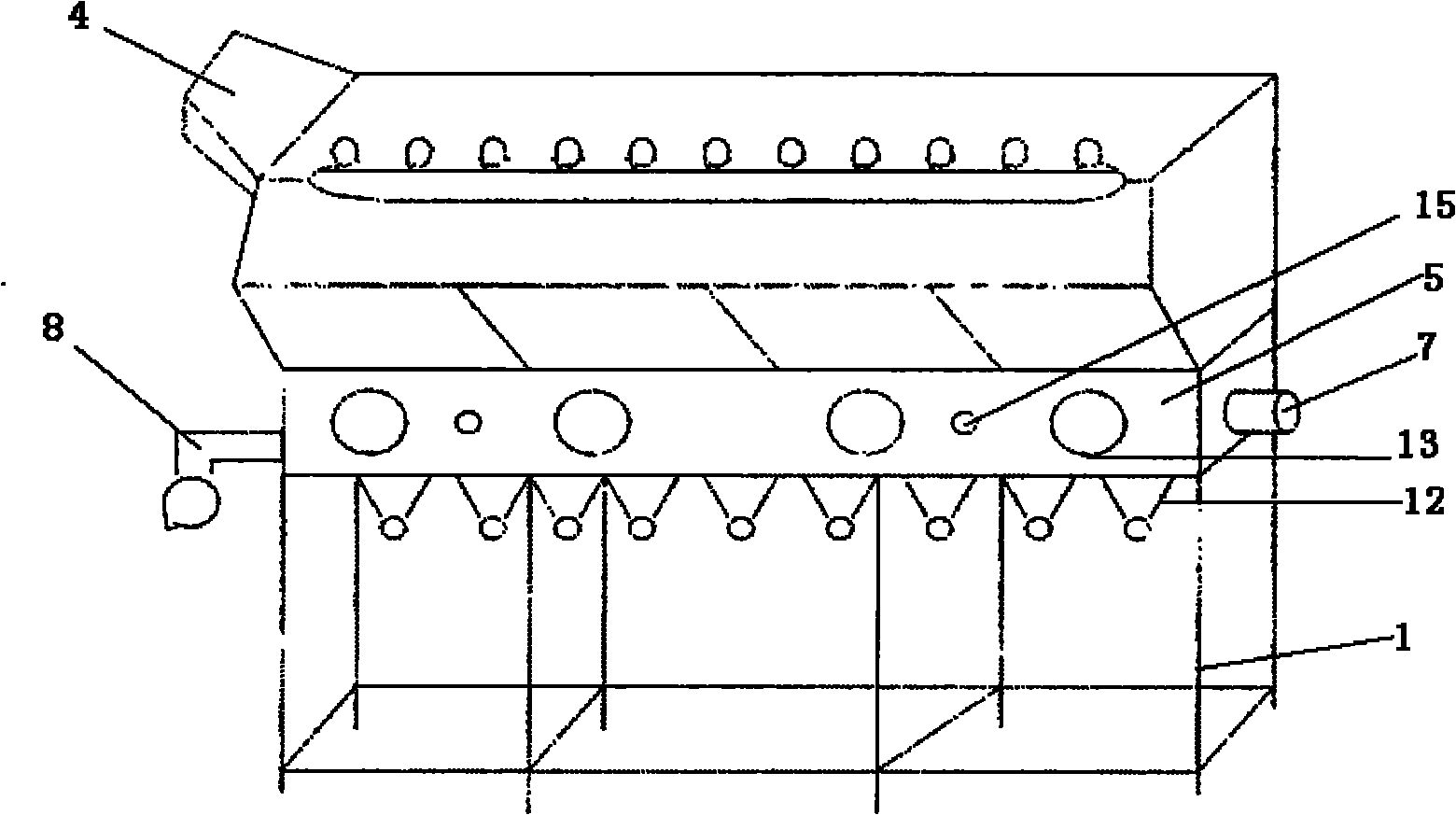

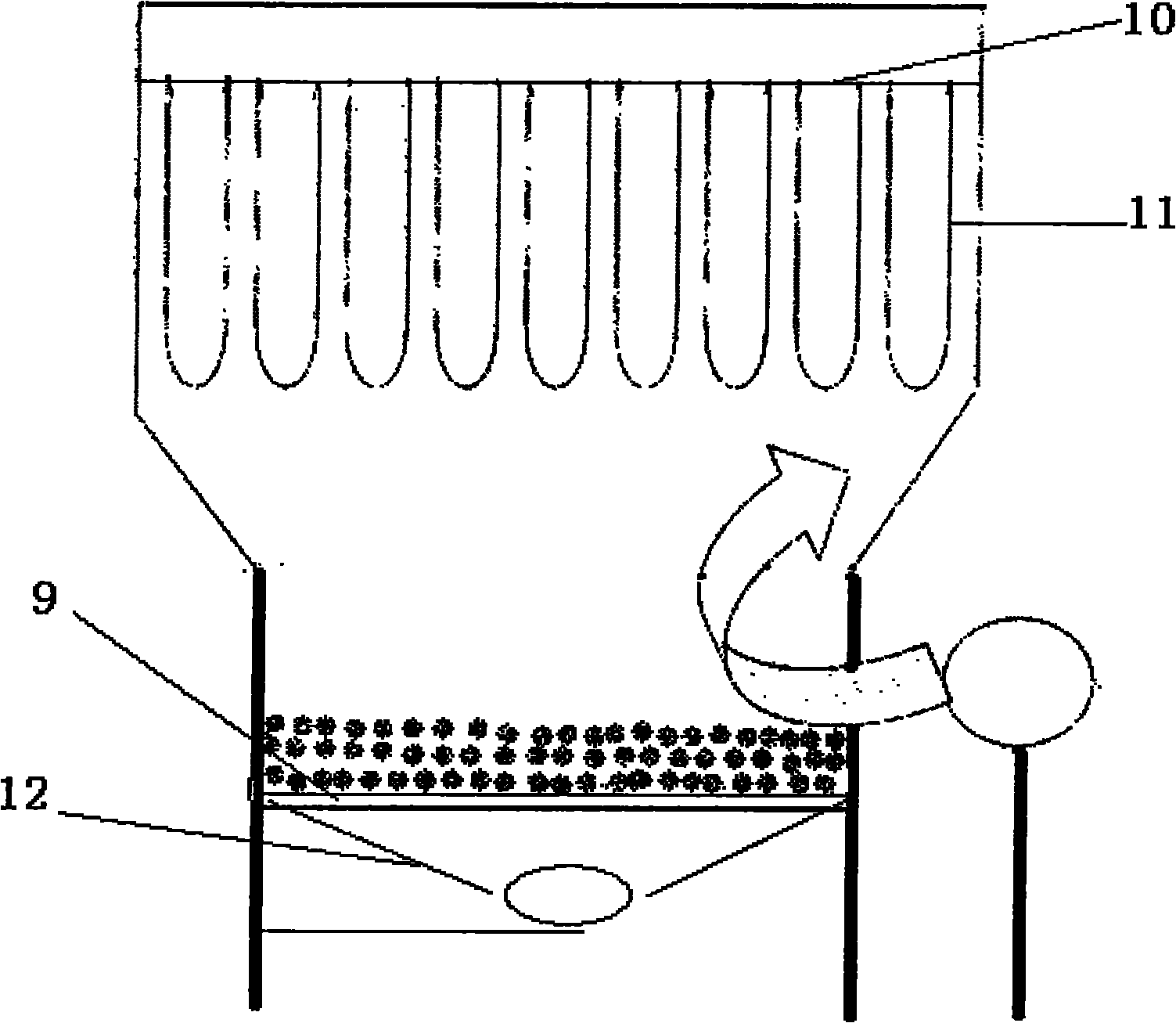

[0016] Referring to the accompanying drawings, a production device for anhydrous oxalic acid includes a support 1, a hot air chamber 2 is arranged above the support 1, a hot air inlet 3 is opened at one end of the hot air chamber 2, the hot air inlet is connected with a hot air inlet pipe, and the air outlet is connected with a The air outlet duct; the other end of the hot air inlet duct is connected with a blower, and the outlet air temperature probe is arranged in the outlet duct, and the outlet air temperature probe is electrically connected with the temperature adjustment switch of the blower fan; the hot air chamber 2 is fixedly installed The drying chamber 5, the hot air chamber 2 and the drying chamber 5 are connected through several pipelines with air volume regulating valves 6, and the two sides of the drying chamber 5 are respectively provided with a negative pressure inlet 7 and an air-closing outlet. 8. There is a slanted hole plate 9 inside the drying chamber 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com