Liquid crystal composition and application thereof

A technology of liquid crystal composition and liquid crystal compound, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of increased rotational viscosity, increased threshold voltage and rotational viscosity, increased birefringence of liquid crystal composition, etc., reaching the upper limit The effect of high temperature, low minimum temperature and high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

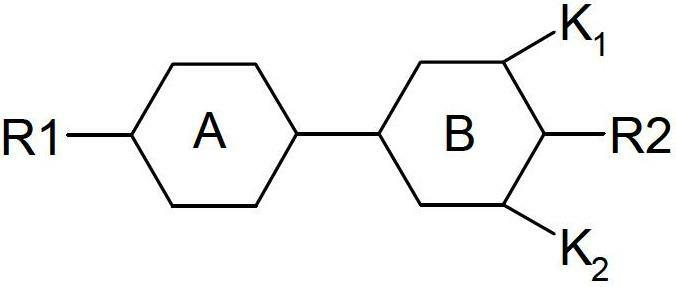

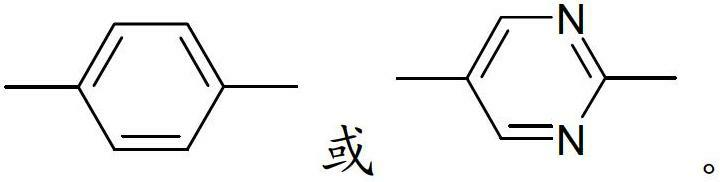

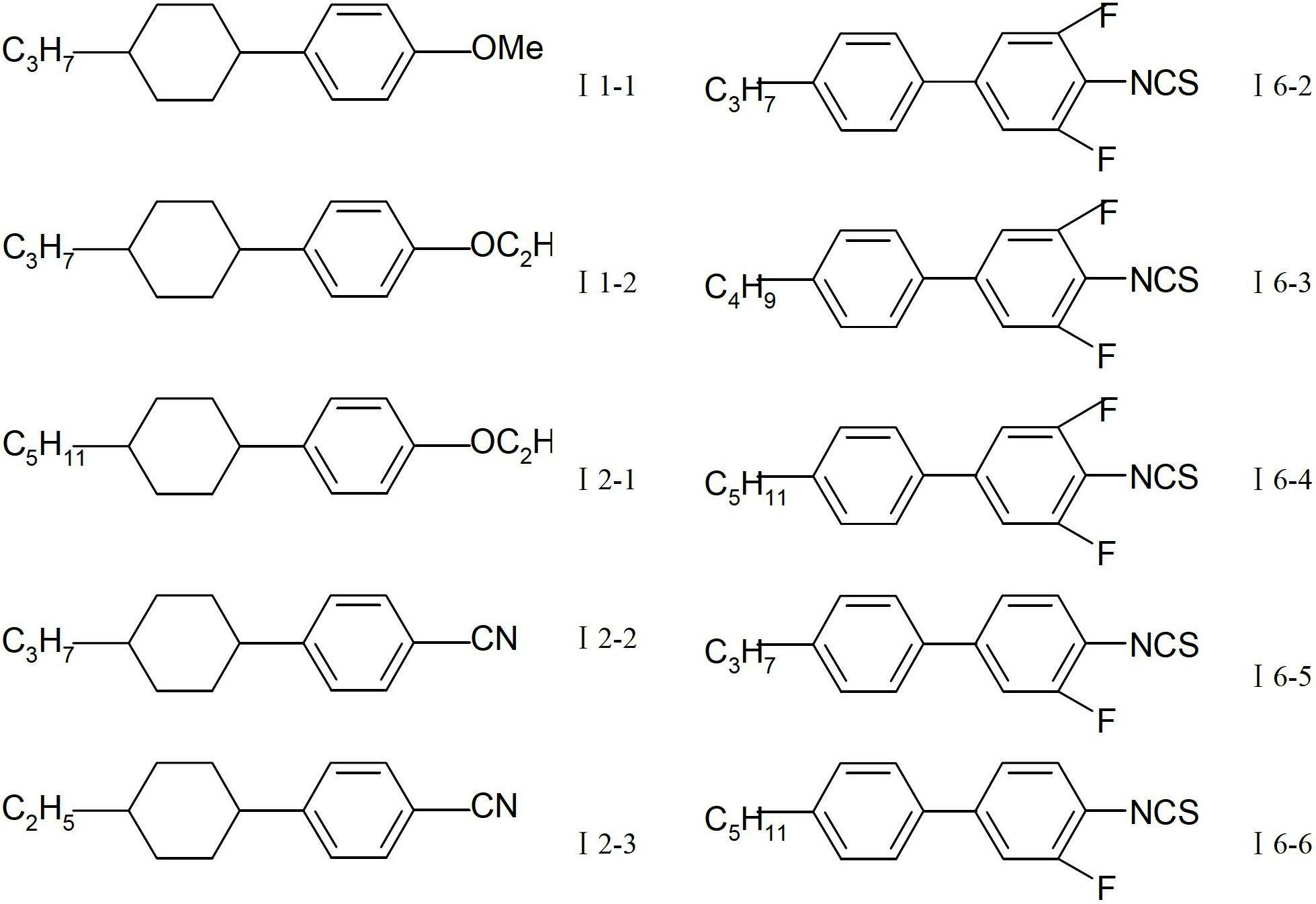

Method used

Image

Examples

Embodiment 1

[0099] The nematic liquid crystal composition of embodiment 1 is made up of following compound, and wherein percentage represents mass fraction:

[0100]

[0101] The nematic liquid crystal composition performance parameter table of this embodiment 1

[0102] Tni:

[0103] ε∥

[0104] Using the liquid crystal lens grating of the liquid crystal composition, its response time T=540ms, the corresponding liquid crystal lens focal length f=1.02mm; and using the liquid crystal material E7 that is currently on the market, its response time T=1210ms, the corresponding liquid crystal lens Focal length f = 1.85mm. Then using the liquid crystal material of the present invention, the response time is increased by 55%, and the focal length is reduced by 45%.

Embodiment 2

[0106] The nematic liquid crystal composition of embodiment 2 is made up of following compound, and wherein percentage represents mass fraction:

[0107]

[0108]

[0109] The nematic liquid crystal composition performance parameter table of this embodiment 2

[0110] Tni:

[0111] Using the liquid crystal lens grating of the liquid crystal composition, its response time T=500ms, the corresponding liquid crystal lens focal length f=1.08mm; and using the liquid crystal material E7 that is currently on the market, its response time T=1210ms, the corresponding liquid crystal lens Focal length f = 1.85mm. Then using the liquid crystal material of the present invention, the response time is increased by 59%, and the focal length is reduced by 42%.

Embodiment 3

[0113] The nematic liquid crystal composition of embodiment 3 is made up of following compound, and wherein percentage represents mass fraction:

[0114]

[0115]

[0116] The nematic liquid crystal composition performance parameter table of this embodiment 3

[0117] Tni:

[0118] The liquid crystal lens grating using this liquid crystal composition has a response time of T=605ms, and the corresponding focal length of the liquid crystal lens is f=1.10mm; while using the liquid crystal material E7 currently on the market, its response time is T=1210ms, and the corresponding liquid crystal lens Focal length f = 1.85mm. Then using the liquid crystal material of the present invention, the response time is increased by 50%, and the focal length is reduced by 41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com