Framed large-span combined pre-stress highway bridge and preparation process thereof

A highway bridge and prestressing technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve problems such as increasing project cost, and achieve the effect of increasing bearing capacity and reducing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

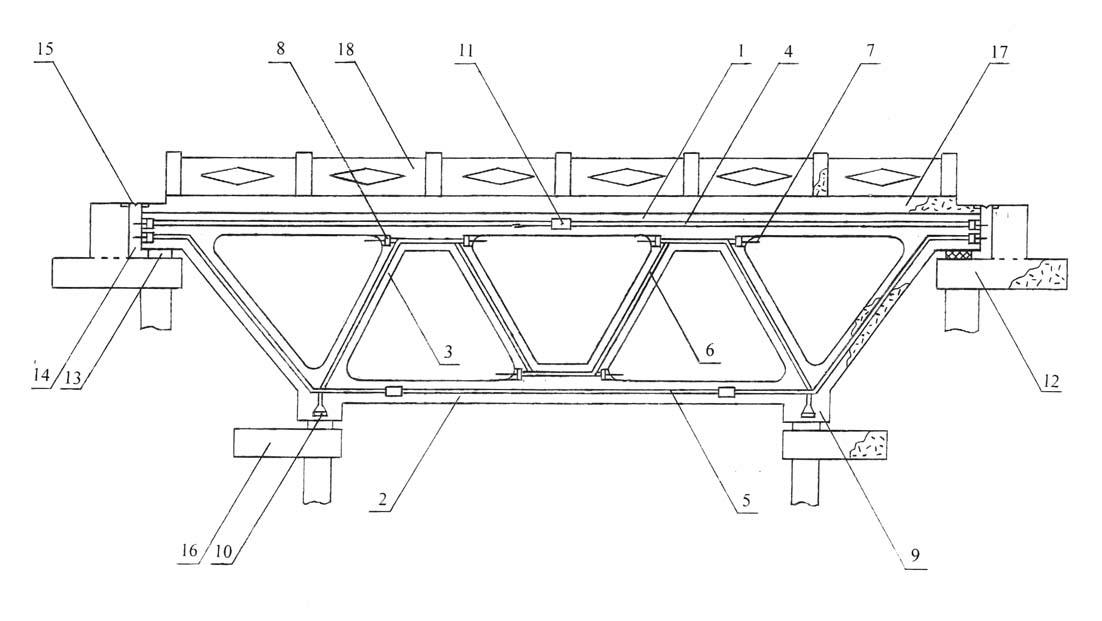

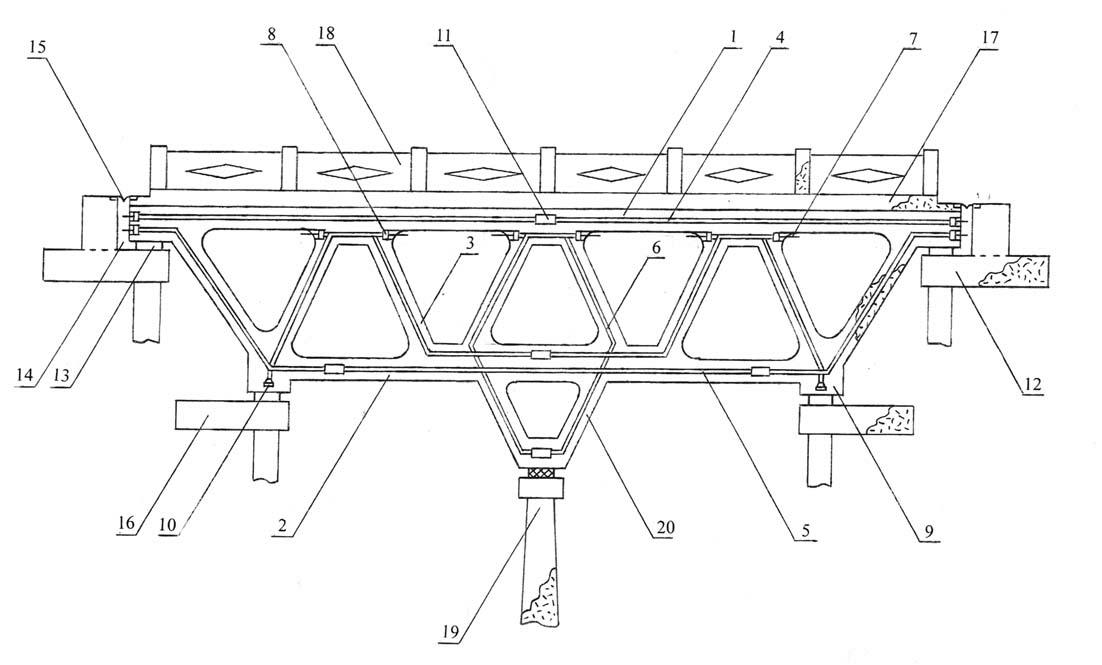

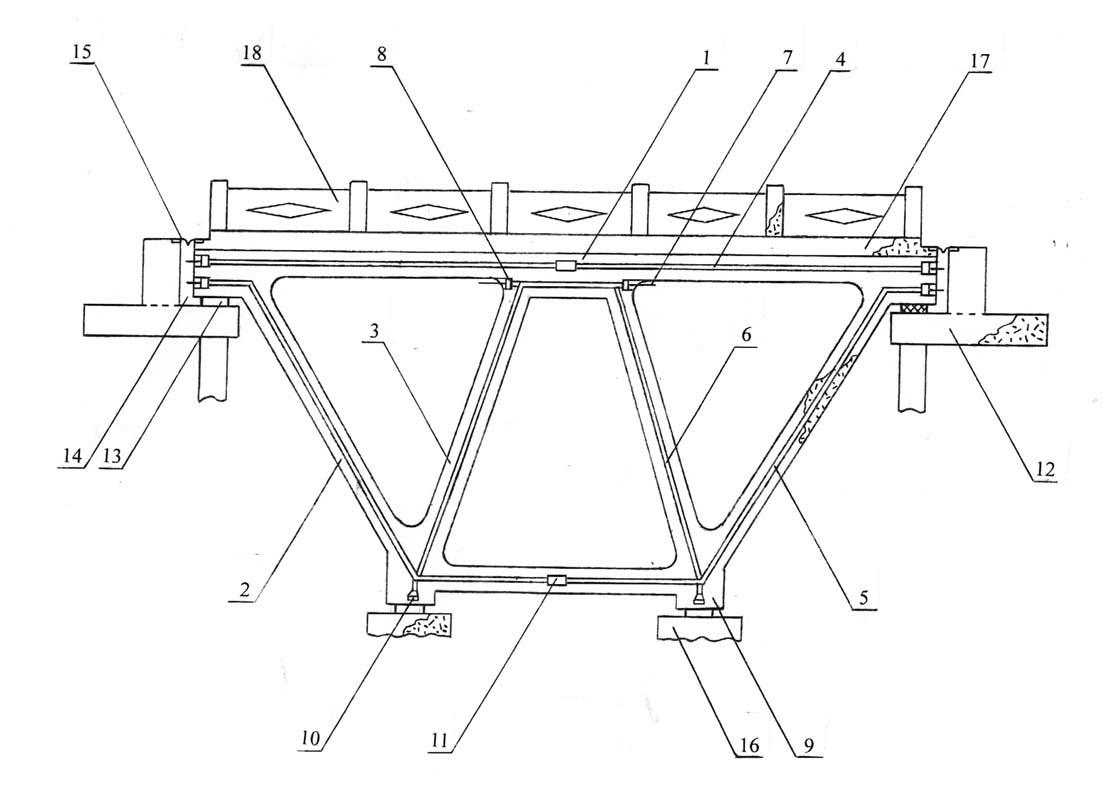

[0038] The present invention will be discussed in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention includes a frame bridge body 1, a composite bottom beam 2 and a figure-eight connection beam 3 arranged at the bottom of the frame bridge body 1; A steel strand 7 that is prestressed by tension is provided, and the steel strand 7 is anchored on the upper end surface of the frame bridge body 1 with a tension end anchor 8 .

[0039] The composite bottom beam 2 is provided with a composite bobbin 5, and a steel strand 7 which is tensioned to generate prestress is arranged in the composite bobbin 5, and the steel strand 7 is fixed with a tension end anchorage 8. The lower part of the end face of the frame bridge body 1 is anchored.

[0040]A connecting bobbin 6 is arranged in the said eight-shaped connecting beam 3, a steel strand 7 is arranged in the connecting copper pipe 6, and a fixed end anchorage 10 is arranged at the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com