Full-automatic liquid nitrogen filling device and control method thereof

A filling device, fully automatic technology, applied in gas/liquid distribution and storage, piping systems, mechanical equipment, etc., can solve the problems of temperature sensor damage, heavy equipment weight, incompatibility with magnetic resonance equipment, etc., and achieve a high degree of freedom , The effect of precise and fast dosing

Inactive Publication Date: 2012-09-12

TIME MEDICAL JIANGSU

View PDF3 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The early liquid nitrogen filling was in the form of a foot-operated self-boosting liquid nitrogen pump. This method of adding liquid nitrogen cannot continue to work for a long time, and the weight of the equipment is relatively large, and it is not compatible with magnetic resonance equipment.

And another method that relies on the liquid level sensor to continuously add liquid nitrogen, although it can keep the liquid level constant, but because the liquid level material is a magnetic material, it cannot be compatible with magnetic resonance, and the commonly used semiconductor temperature sensor will easily will be damaged, crystal oscillator type temperature sensors will not work in magnetic fields

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

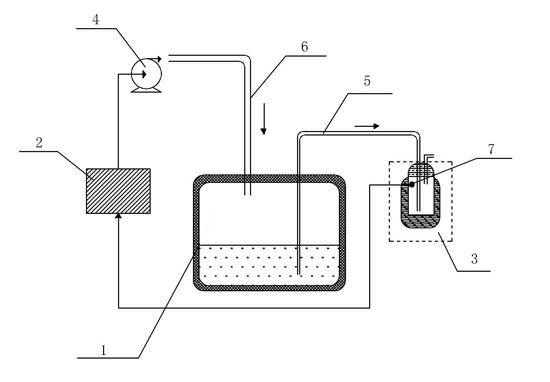

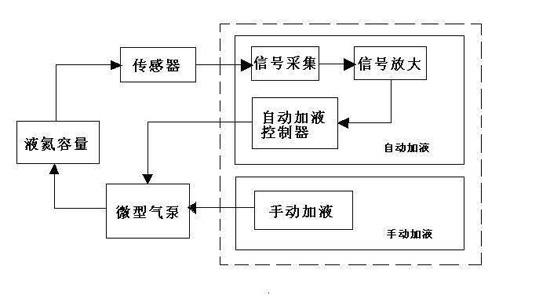

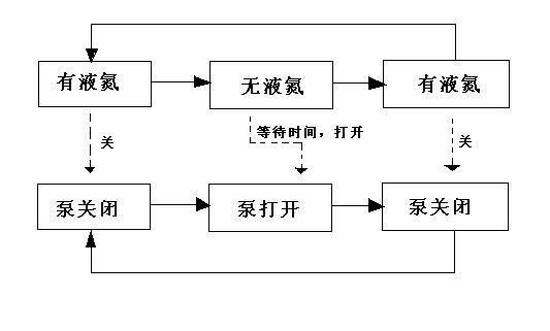

The invention discloses a full-automatic liquid nitrogen filling device and a control method thereof. A temperature sensor (7) is arranged in a liquid nitrogen container (3) in a high temperature superconducting coil, and a liquid nitrogen delivery pipe (5) is arranged between a liquid nitrogen dewar (1) and the liquid nitrogen container (3) in the high temperature superconducting coil. When liquid nitrogen in the liquid nitrogen container (3) in the high temperature superconducting coil achieves the low position, a liquid adding controller (2) delivers liquid nitrogen low position temperature marginal value information according to the temperature sensor (7) to be instruments to start up a miniature pump (4) to open a switch, the miniature pump is opened, and air presses the liquid nitrogen in the liquid nitrogen dewar (1) into the liquid nitrogen container (3) in the high temperature superconducting coil. When liquid nitrogen in the liquid nitrogen container (3) in the high temperature superconducting coil achieves the high position, the liquid adding controller (2) delivers liquid nitrogen high position temperature marginal value information according to the temperature sensor (7) to be instruments to start up the miniature pump (4) to close a switch, and liquid nitrogen adding is stopped. The full-automatic liquid nitrogen filling device can automatically or manually add liquid, and is free of influences of magnetic resonance magnetic fields and electric fields.

Description

technical field [0001] The invention relates to a fully automatic liquid nitrogen filling device applied to magnetic resonance and a control method thereof. Background technique The early liquid nitrogen filling was in the form of a foot-operated self-boosting liquid nitrogen pump. This method of adding liquid nitrogen could not continue to work for a long time, and the equipment was heavy, and it was not compatible with magnetic resonance equipment. And another method that relies on the liquid level sensor to continuously add liquid nitrogen, although it can keep the liquid level constant, but because the liquid level material is a magnetic material, it cannot be compatible with magnetic resonance, and the commonly used semiconductor temperature sensor will easily will be damaged, crystal oscillator type temperature sensors will not work in magnetic fields. Contents of the invention The technical problem to be solved by the present invention is to provide a device and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F17D1/02F17D3/01

Inventor 涂炜旻徐光福胡长伍刘尊钢高而震马启元

Owner TIME MEDICAL JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com