Method for separating and processing marine oily water and processing device thereof

A separation treatment and treatment device technology, applied in water treatment devices, ship parts, ship construction, etc., can solve problems such as high viscosity, separation membrane pollution, incomplete separation, etc., and achieve the effect of saving cabin space and increasing coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

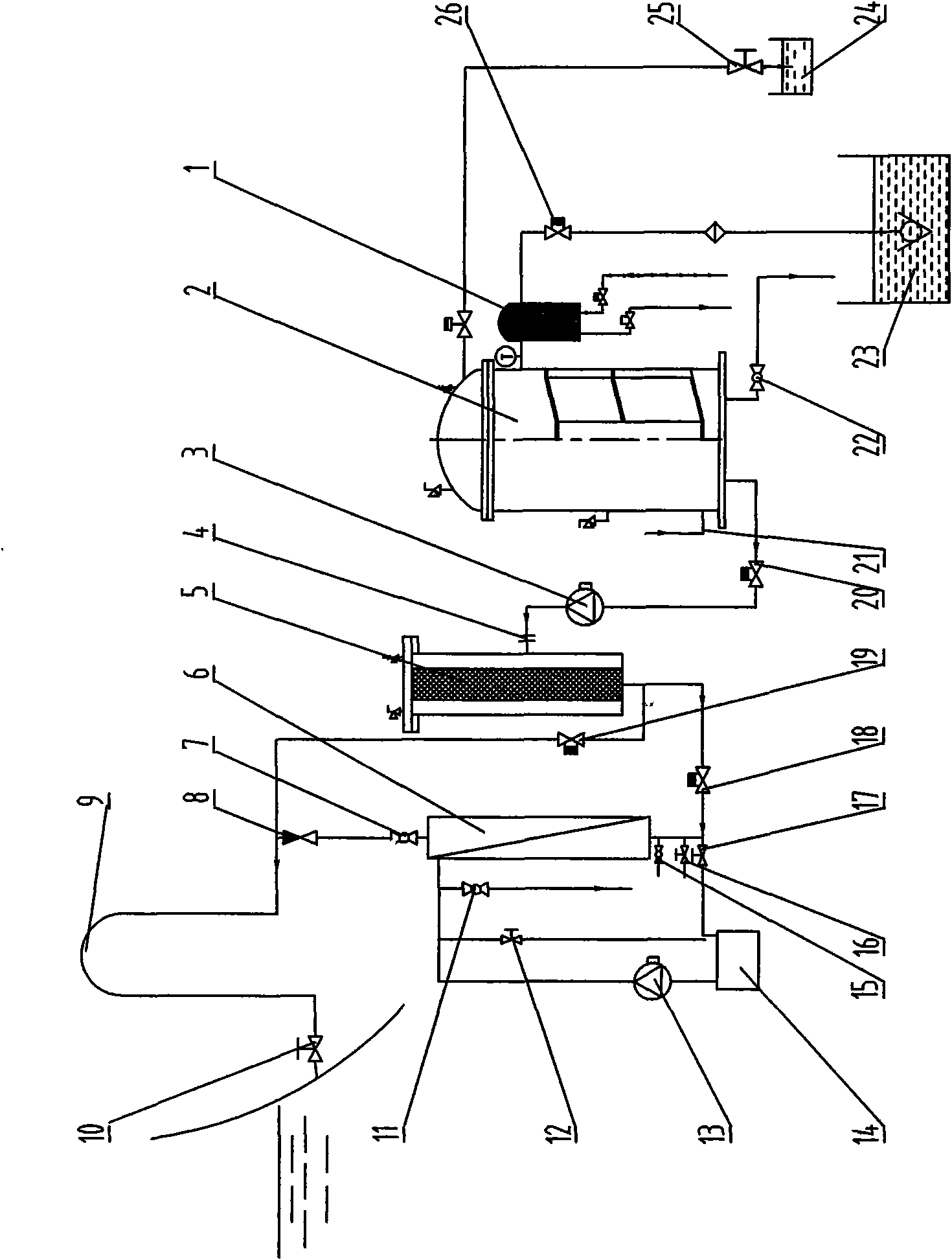

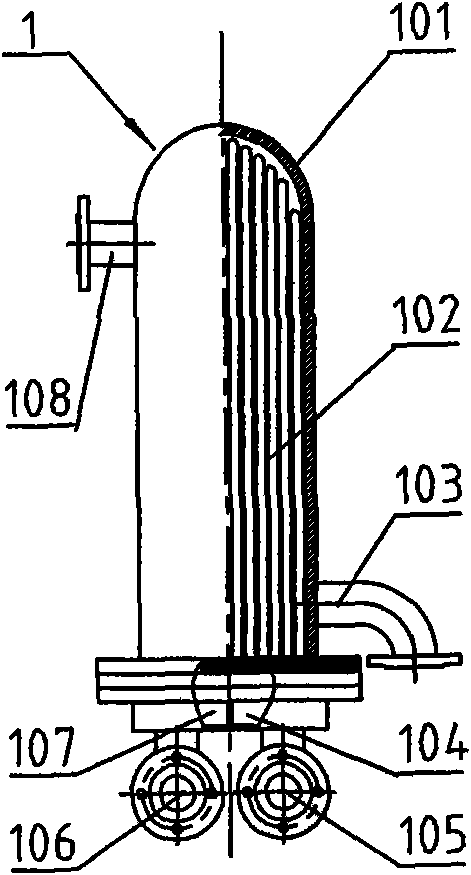

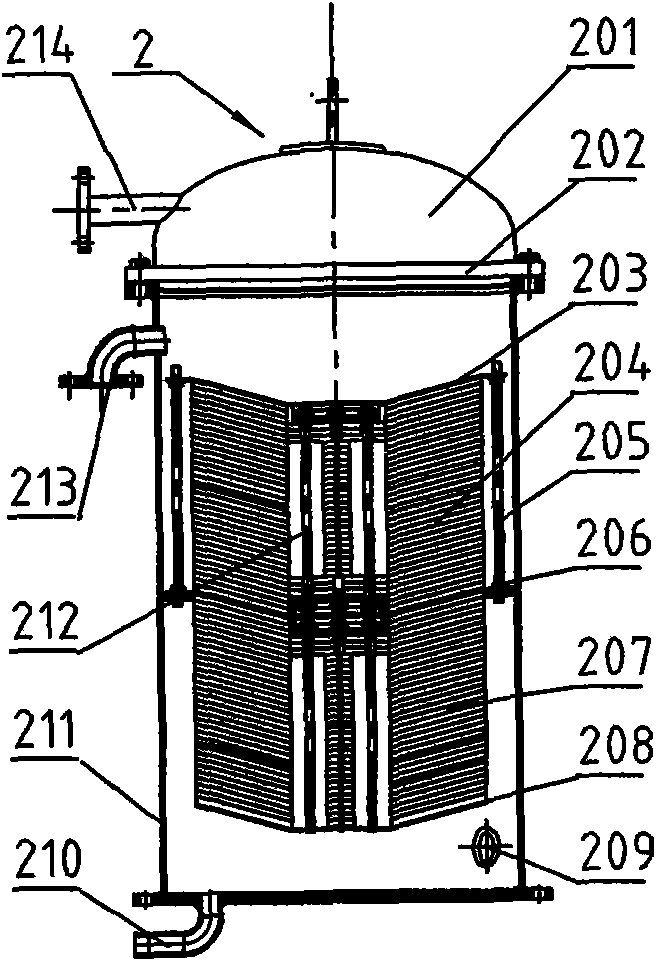

[0037] like figure 1As shown, the marine oily sewage treatment device includes a heater 1, a gravity separator 2, a suction pump 3, a filter material filter 5 and a membrane processor 6 connected in sequence through pipelines; the filtered water outlet of the filter material filter 5 It communicates with the filtered water inlet 608 of the membrane processor 6 and the sea valve 10 connected to each other. Under the action of the suction pump 3, the oily sewage in the bilge oily sewage station 23 enters the heater 1 through the oily sewage input valve 26, and the suction pump 3 adopts a screw pump; The oily sewage is preheated to 48°C to 58°C, preferably the preheating temperature is controlled between 52°C to 56°C. The preheated oily water is continuously sucked into the gravity separator 2. The upper part of the gravity separator 2 is a static separation chamber with a dome-shaped top cover, and the lower part of the cylinder chamber is equipped with a collection separator f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com