Reflect type microlens optical engine illumination system

A lighting system and light engine technology, applied in optics, optical components, instruments, etc., can solve the problems of large loss of light energy and difficult assembly, and achieve the effect of reducing the difficulty of the process and improving the utilization rate of light energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

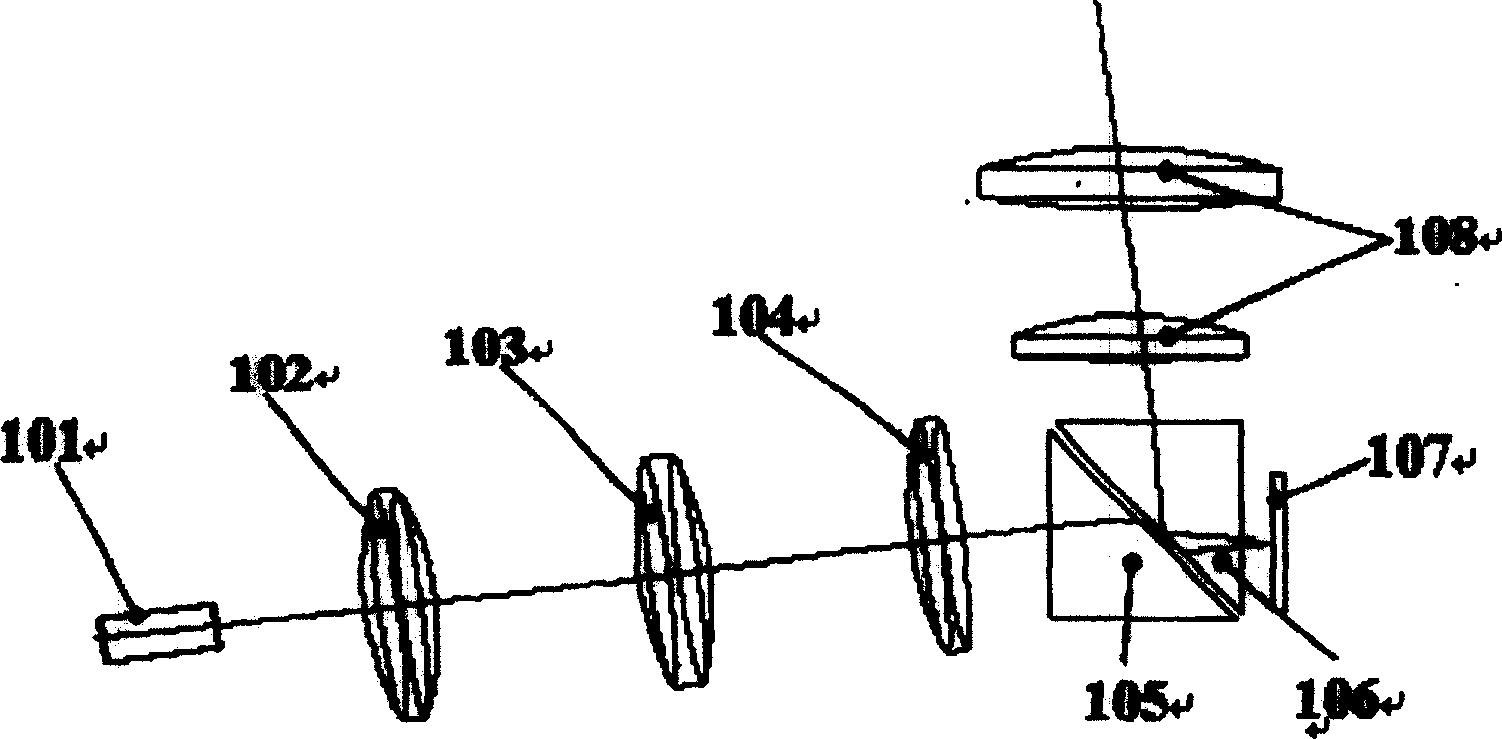

[0009] figure 1 It is the light path diagram of the illumination light path of the existing reflective micromirror light engine. The light emitted by the light pipe 101 is incident on the refracting prism 105 through the illuminating lenses 102 , 103 , 104 . The incident angle of light on the slope of the refracting prism 105 is smaller than the critical angle of total reflection. The light emitted from the oblique surface of the refracting prism 105 is incident on the reflective micromirror 107 through the reflective prism 106 . Since the exit faces of 107 and 101 are non-conjugated, the light spot formed on 107 is rhombus or trapezoid. The light is incident on the slope of the reflective prism 106 after being reflected by the reflective micromirror 107 . The incident angle of the light on the slope of the reflective prism 106 is greater than the critical angle of total reflection. The light reflected by the slope 106 is imaged onto the screen by the projection lens 108 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com