A kind of screen paint formula and spraying method thereof for rear projection

A technology of rear projection and screen, applied in the field of paint, can solve the problems of poor projection effect and poor light transmission, and achieve the effect of good projection effect and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

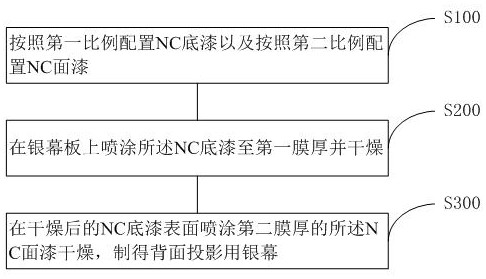

Method used

Image

Examples

Embodiment 1

[0057] A formula for screen paint for rear projection, NC primer includes 10 parts of flat white NC paint and 15 parts of NC paint thinner, NC topcoat includes 10 parts of semi-matte NC paint, 2 parts of silver white pearlescent powder and 15 parts of NC paint thinner agent. Among them, flat white NC paint includes 20 parts of ester solvent, 20 parts of nitrocellulose, 10 parts of maleic acid modified rosin resin, 12 parts of modified saturated polyester resin, 3 parts of dioctyl phthalate, 5 parts Zinc stearate and 2 parts talc, semi-matt NC lacquer consisting of 15 parts nitrocellulose, 10 parts acrylic resin, 15 parts modified rosin resin, 2 parts dioctyl ester and 30 parts ethyl acetate, NC lacquer thinner Contains 30 parts dimethyl carbonate, 50 parts butyl acetate, 10 parts isobutanol, and 8 parts propylene glycol methyl ether acetate.

[0058] Spraying method: first use alcohol to clean the surface of the screen plate, then take a portion of the above-mentioned NC prim...

Embodiment 2

[0060] A formula of screen paint for rear projection, NC primer includes 15 parts of flat white NC paint and 20 parts of NC paint thinner, NC topcoat includes 15 parts of semi-matt NC paint, 3 parts of silver white pearlescent powder and 20 parts of NC paint thinner agent. Among them, flat white NC paint includes 30 parts of ester solvent, 25 parts of nitrocellulose, 12 parts of maleic acid modified rosin resin, 15 parts of modified saturated polyester resin, 4 parts of dioctyl phthalate, 7 parts Zinc stearate and 3 parts talc, semi-matt NC lacquer consisting of 20 parts nitrocellulose, 15 parts acrylic resin, 20 parts modified rosin resin, 5 parts dioctyl ester and 40 parts ethyl acetate, NC lacquer thinner Contains 40 parts dimethyl carbonate, 60 parts butyl acetate, 20 parts isobutanol, and 12 parts propylene glycol methyl ether acetate.

[0061] Spraying method: first use alcohol to clean the surface of the screen plate, then take a portion of the above-mentioned NC prime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com