Light driving scanning micro-mirror

A scanning micromirror and light-driven technology, applied in optics, optical components, microstructure technology, etc., can solve the problems of metal wire bonding process failure, avoid metal wire bonding process, reduce device size, and improve reliability. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

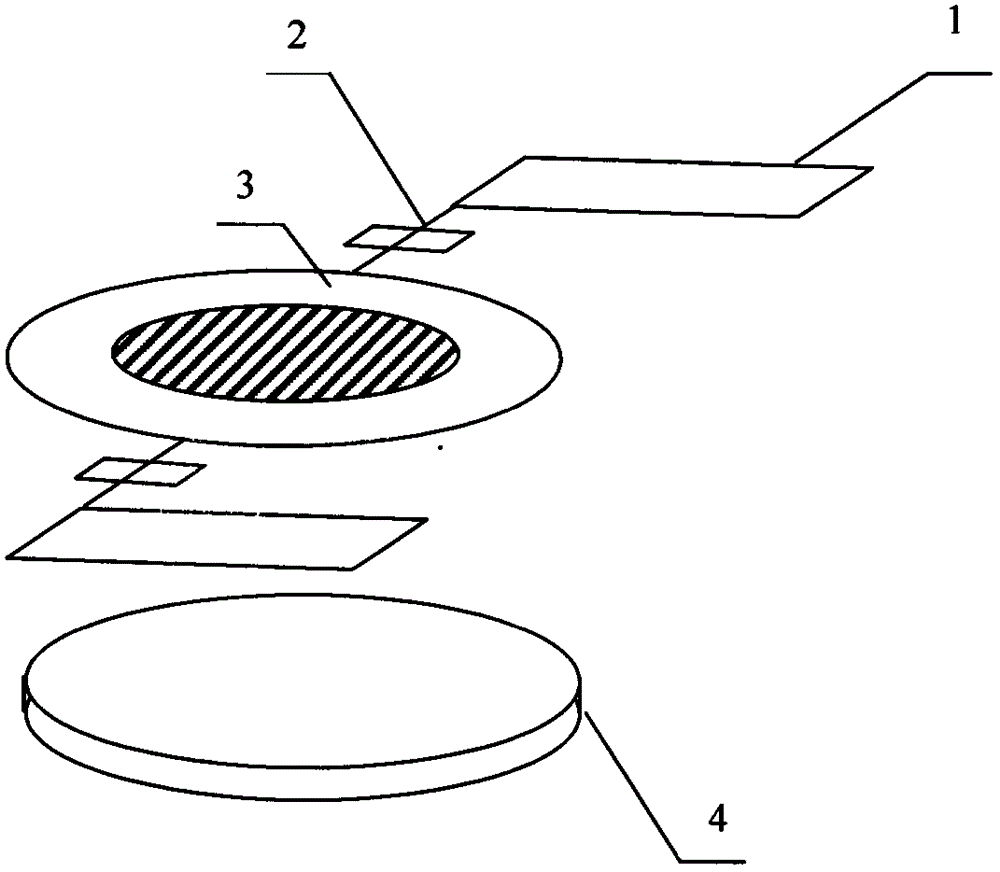

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as Figure 1-2 As shown, it includes a micro-driver 1, a planar spring 2, a movable mirror 3 and a photocell 4. The output end of the micro-driver 1 is connected with the input end of the planar spring 2, the output end of the planar spring 2 is connected with the input end of the movable mirror 3, and the output end of the photocell 4 is connected with the input end of the micro-driver 1; each device includes 1 A movable mirror 3, two planar springs 2, two micro-drivers 1 and a photocell 4, the movable mirror 3 is connected with two planar springs 2, and each planar spring 2 is connected with a micro-driver 1;

[0018] The micro-driver 1 is made using micro-machining technology, based on the principle of electrothermal drive, and is composed of multi-layer materials such as silicon, silicon dioxide, metal, metal oxide, etc., and is used to pass the externally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com