Method for adhering bus bar on thin film photovoltaic assembly with conductive silver adhesive

A technology of thin-film photovoltaic modules and conductive silver glue, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of increasing the cost of conductive silver glue, disconnection, affecting normal production and product quality, and ensuring process continuity and Product quality, reducing transportation and storage costs, avoiding the effects of abnormal disconnection of glue dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

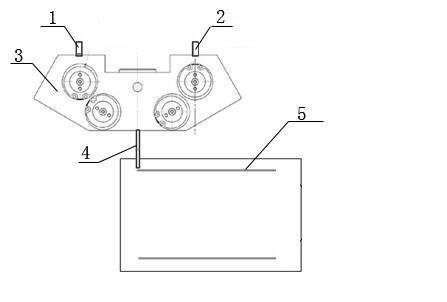

[0017] A method for bonding bus bars with conductive silver glue on thin-film photovoltaic modules, placing two syringes of the same size on both sides of the solar thin-film photovoltaic module glue spraying device 3, and placing two kinds of glue with different components on the two needles respectively. In the barrel, push the piston of the syringe to push the glue into the glue spraying equipment for mixing. By adjusting the pressure of pushing the glue and the speed of glue spraying, the glue of two different components can be mixed into a two-component conductive glue in the glue spraying equipment. Silver glue, the mixed two-component conductive silver glue is extruded through the glue spray head 4 of the glue spraying equipment to form a uniform and continuous glue line 5 on the front plate of the solar thin film photovoltaic module. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com