Equivalent 24 pulse wave non-control rectification DC thawing apparatus

A DC ice-melting and pulse wave technology, applied in the field of electrical engineering, can solve the problems of increased noise and loss of distribution transformers, large harmonic currents, etc., and achieve the effects of small grid harmonics, high cost performance, and low grid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

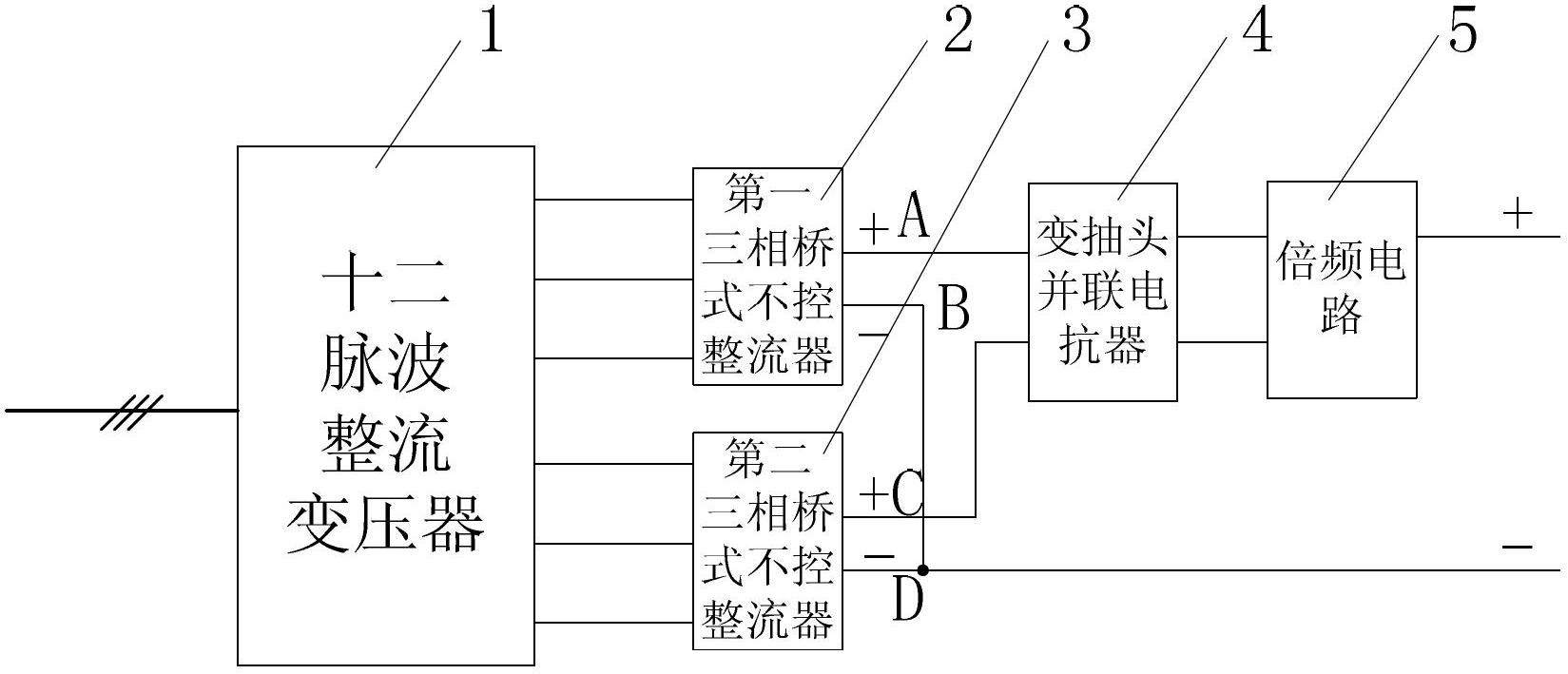

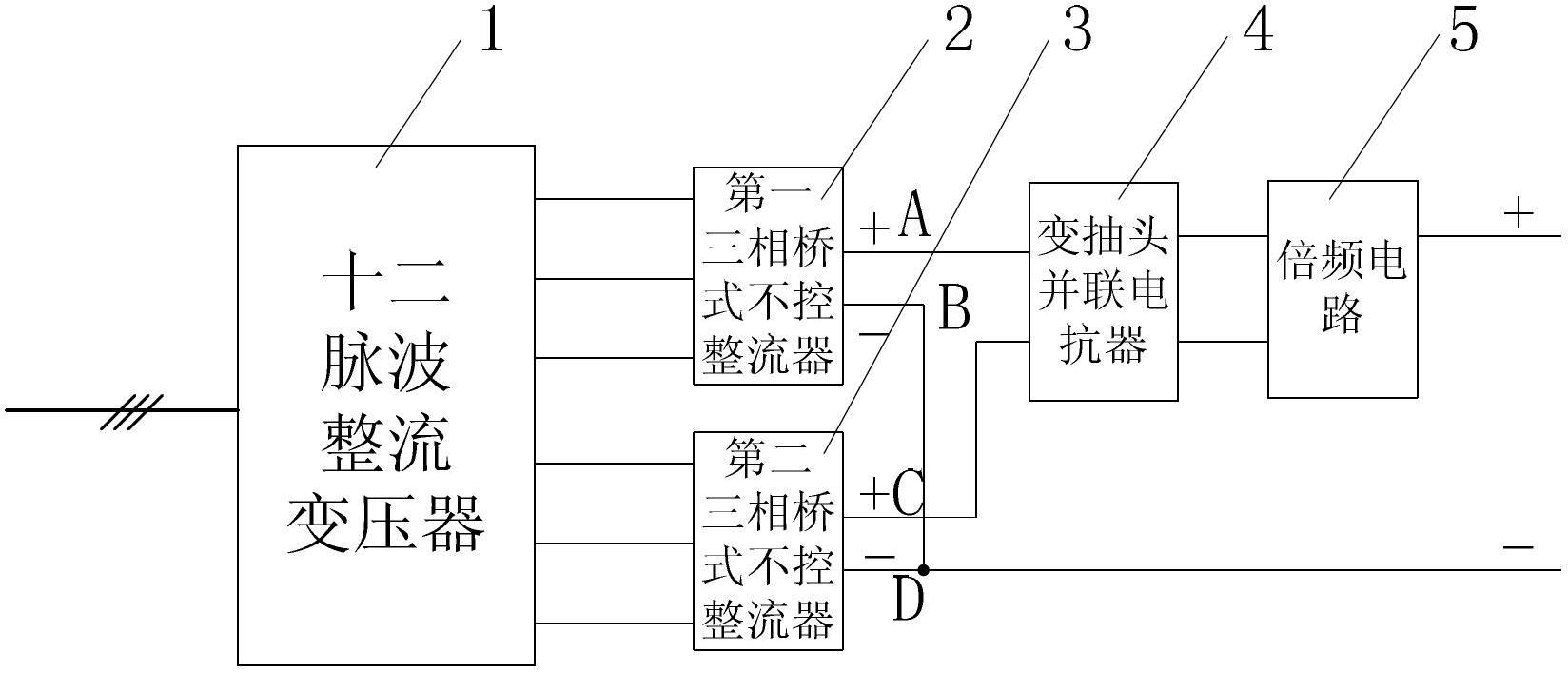

[0020] see figure 1 , figure 1 Shown is a specific embodiment of the equivalent 24-pulse uncontrolled rectification DC ice-melting device of the present invention. The twelve-pulse rectifier transformer 1 of this embodiment adopts the ZSS produced by China TBEA Hengyang Transformer Co., Ltd. Electric Branch -9100 / 10 type 9100kVA rectifier transformer; the first three-phase bridge uncontrolled rectifier 2 and the second three-phase bridge uncontrolled rectifier 3 both adopt ZYAF-1400 4MW three-phase produced by Hunan Huicui Power Technology Co., Ltd. Bridge uncontrolled rectifier; variable tap shunt reactor 4 adopts KE-1400 / 36 reactor produced by Yichang Kaur Electronics Co., Ltd., Hubei Province, China; frequency multiplier circuit 5 adopts ZYAF produced by Hunan Huicui Power Technology Co., Ltd. -2800 type full wave rectifier circuit.

[0021] The twelve-pulse rectifier transformer 1, the first three-phase bridge uncontrolled rectifier 2, the second three-phase bridge uncon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com