Thermoelectricity cooling device of ultrasonic motor

A technology for ultrasonic motors and cooling devices, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of motor temperature rise, heat export, and unsuitable air cooling methods, and achieve the effect of compact structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the concept, specific structure and technical effects of the present invention will be further described in conjunction with the accompanying drawings to fully understand the purpose, features and effects of the present invention.

[0019] The thermoelectric cooling and heat dissipation device of the ultrasonic motor in the present invention uses a thermoelectric cooling sheet to replace the aluminum base of the traditional ultrasonic motor, and uses a heat dissipation layer to absorb heat on the thermoelectric cooling sheet, and the heat dissipation layer is filled with inorganic salt phase change materials for heat absorption , So as to effectively realize the thermoelectric heat dissipation function of the ultrasonic motor, and ensure that it can work continuously for a long time.

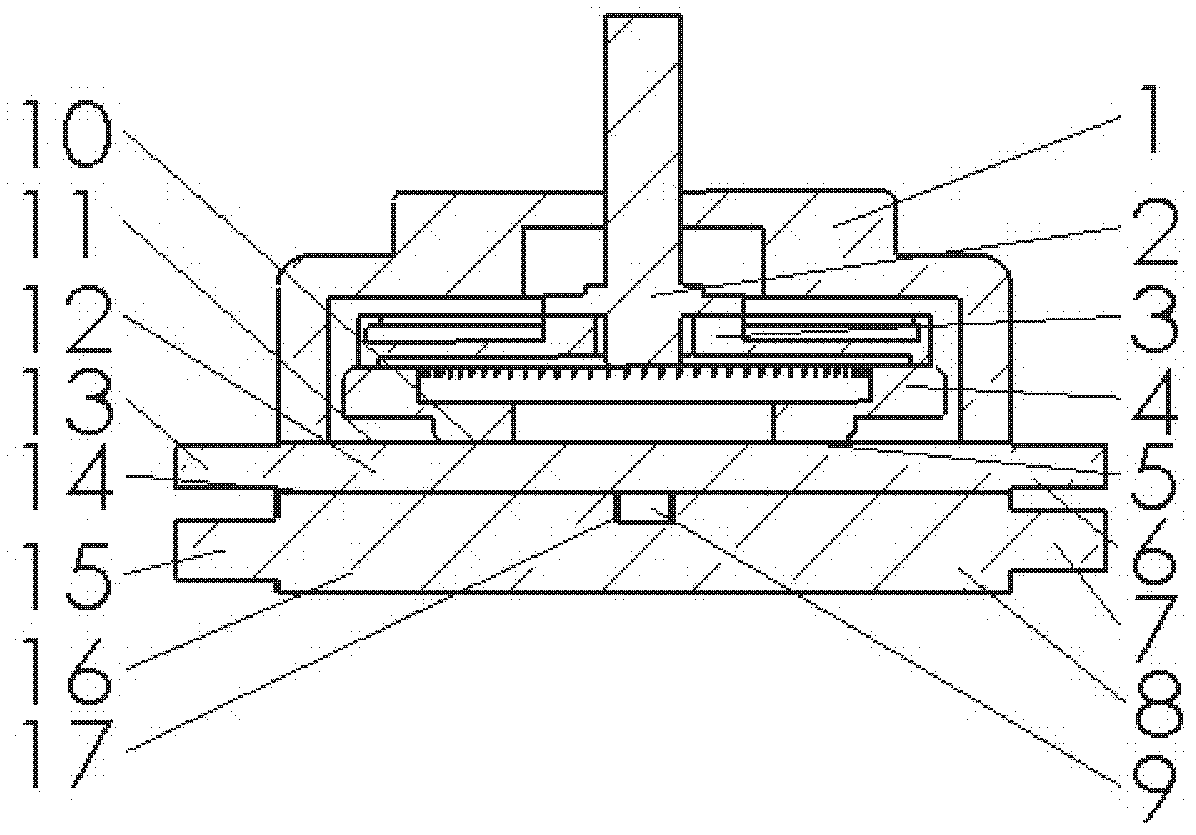

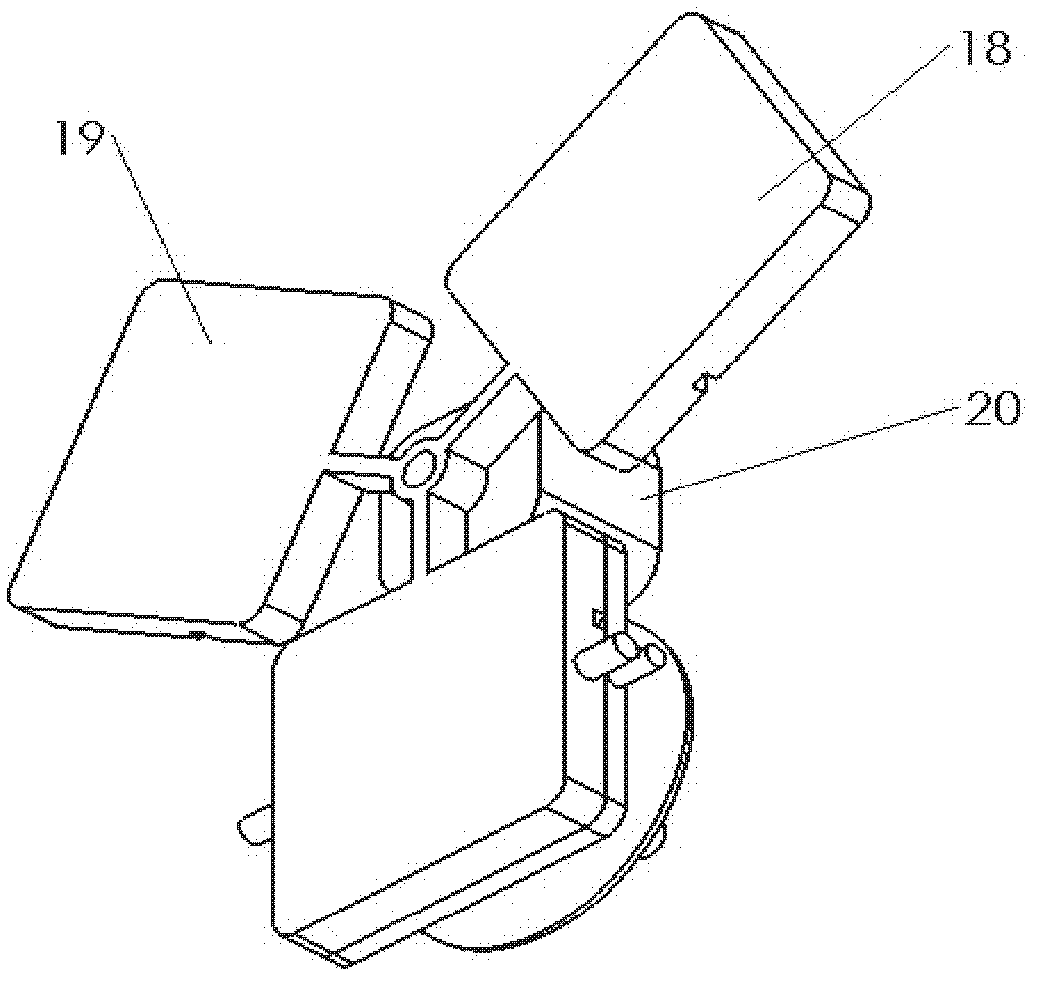

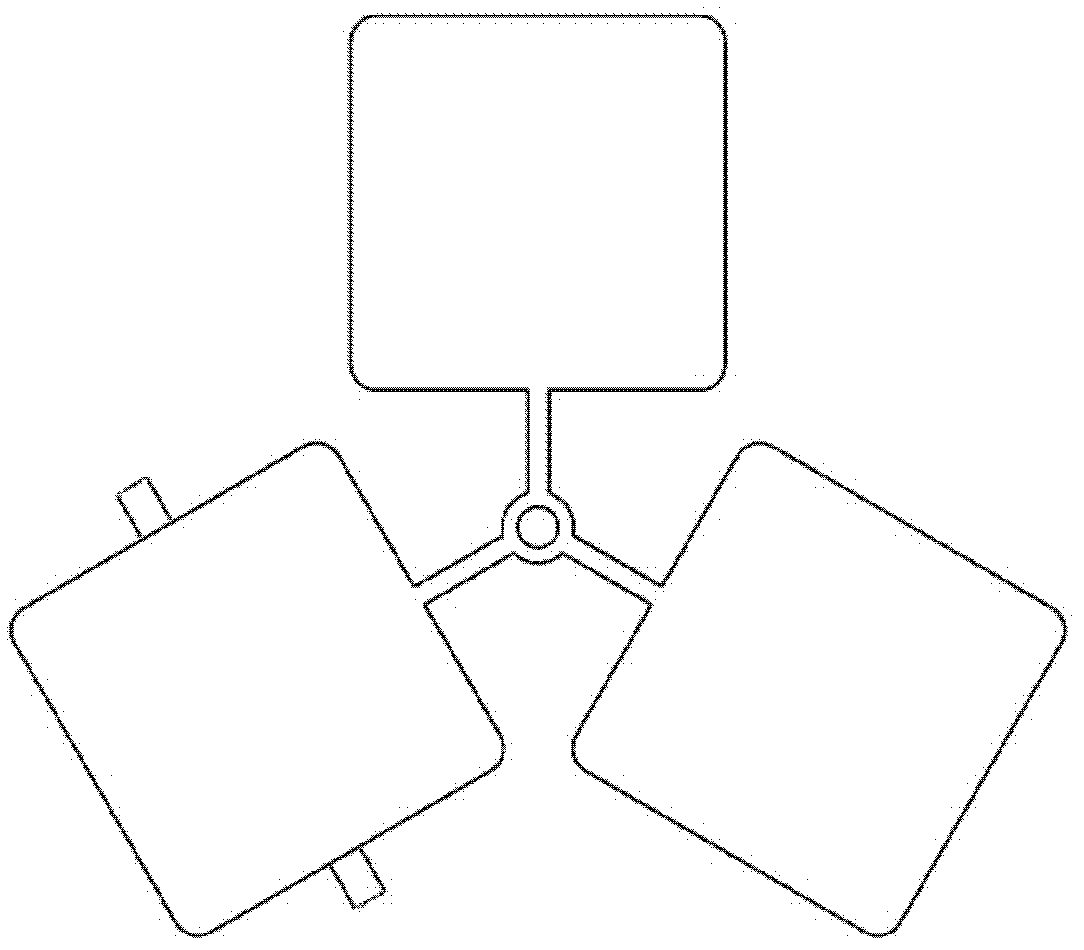

[0020] Such as figure 1 As shown, the ultrasonic motor thermoelectric cooling and heat dissipation device of the present invention includes an ultrasonic motor, a thermoelectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com