LED lamp fault detection system

A technology of LED lighting and fault detection, which is applied in lighting devices, lamp circuit layout, light sources, etc., can solve problems such as system cumbersomeness, multiple resources, and increase the difficulty of system maintenance, and achieve the effect of simplifying structure, reducing maintenance difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

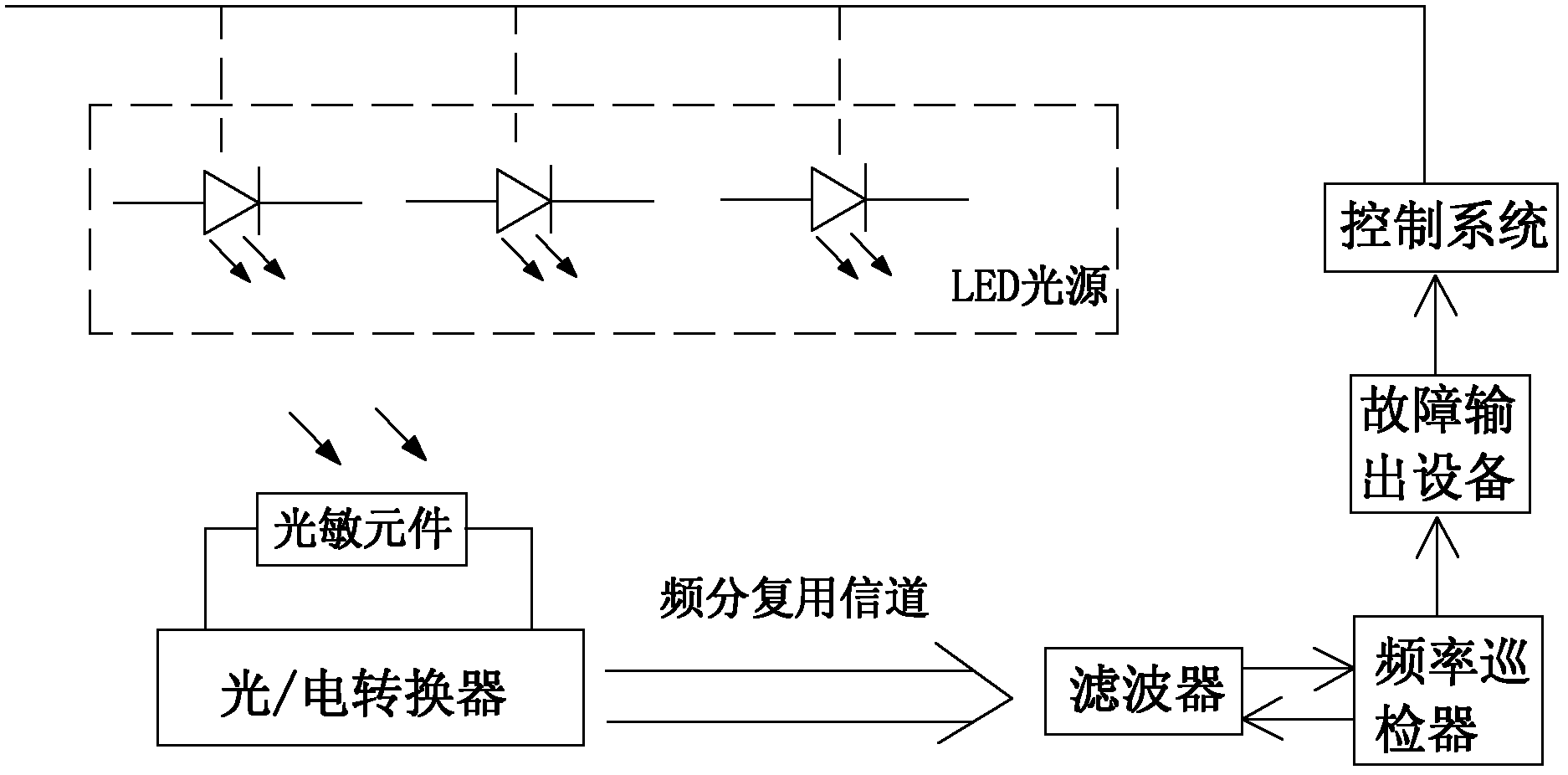

[0013] Such as figure 1 As shown, the fault detection system for LED lighting fixtures of the present invention includes an optical / electrical converter, the input end of the optical / electrical converter is connected with a photosensitive element, and the photosensitive element is a photoresistor or a photodiode. The optical / electrical converter is connected with the frequency patrol device through the frequency division multiplexing channel through the filter. The output end of the frequency patrol device is connected to the control system through the fault output device. When working, the control bus assigns different frequencies to each LED lamp bead, and the photosensitive element senses the different frequency light of each LED lamp bead and transmits it to the optical / electrical converter. The optical / electrical converter performs optical / electrical conversion on the input light of different frequencies, and transmits it to the filter through the frequency division mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com