TFT substrate inspection apparatus and tft substrate inspection method

A substrate inspection and substrate technology, applied in identification devices, measuring devices, instruments, etc., can solve the problems of longer detection time and longer TFT substrate time, and achieve the effect of improving detection accuracy and shortening defect detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

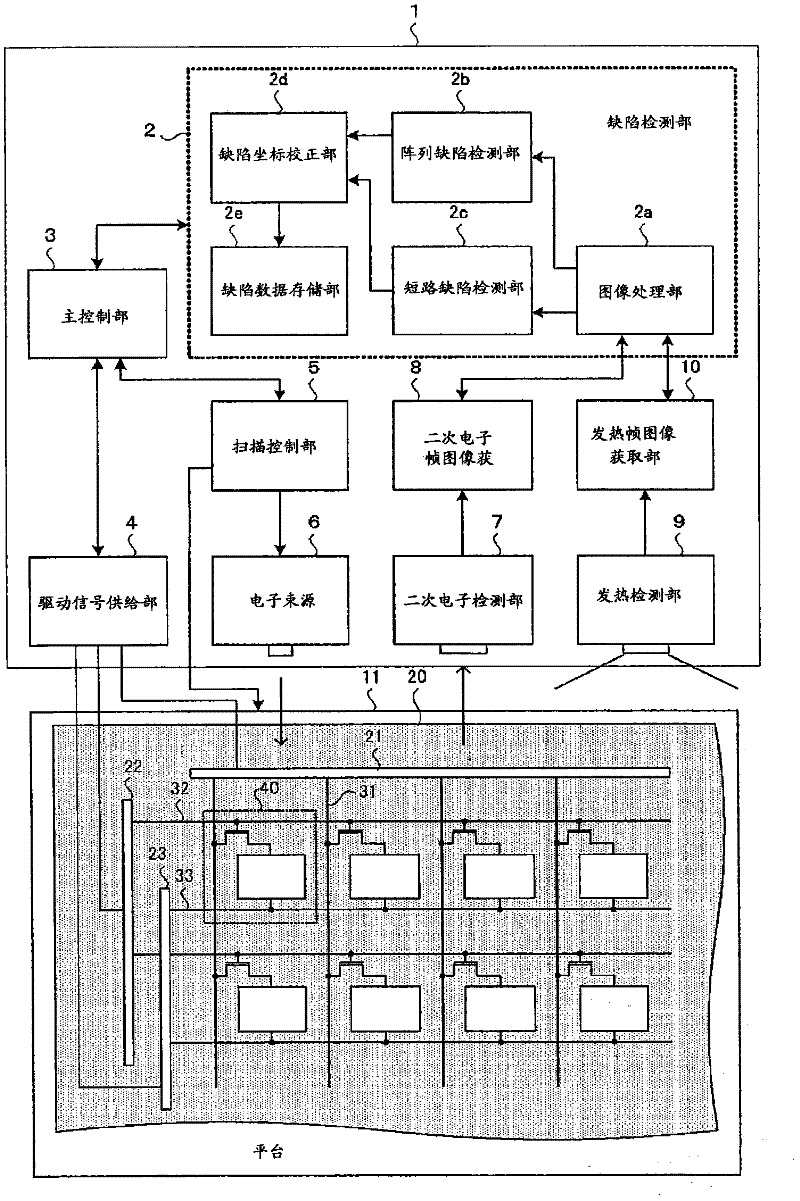

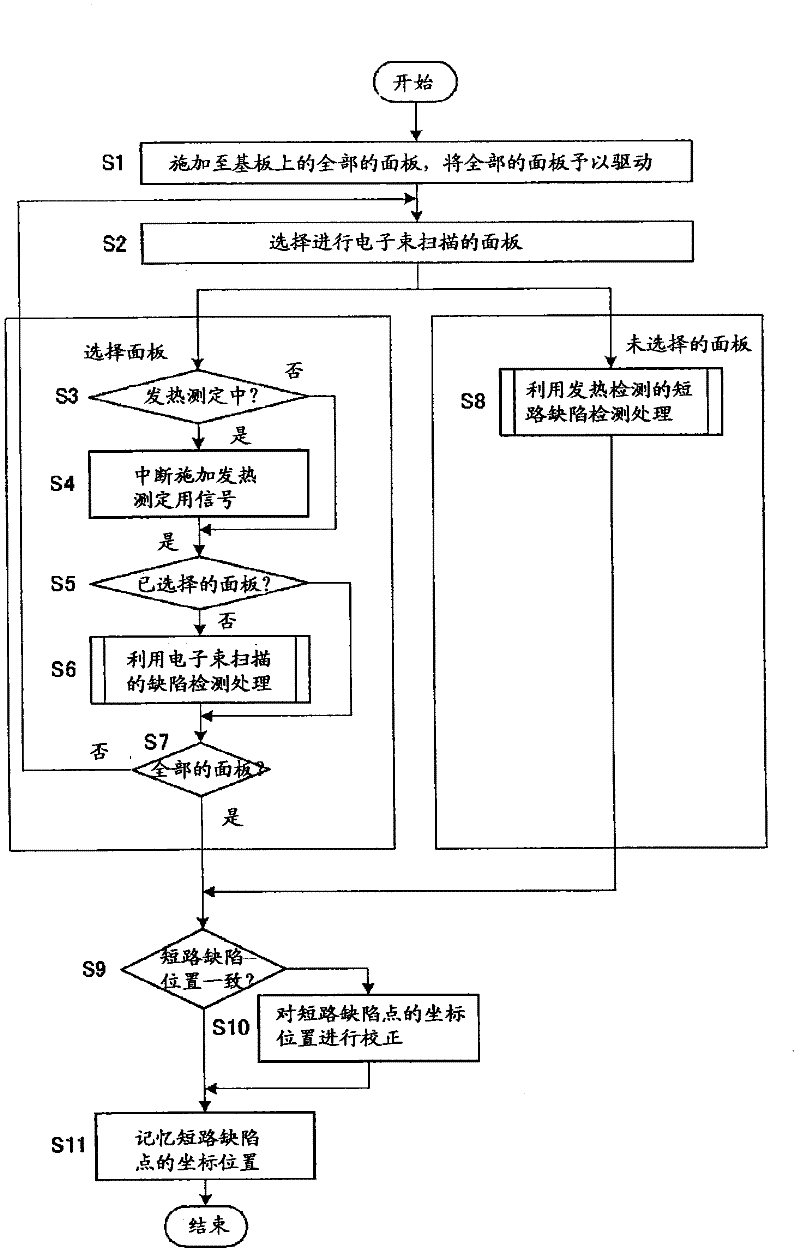

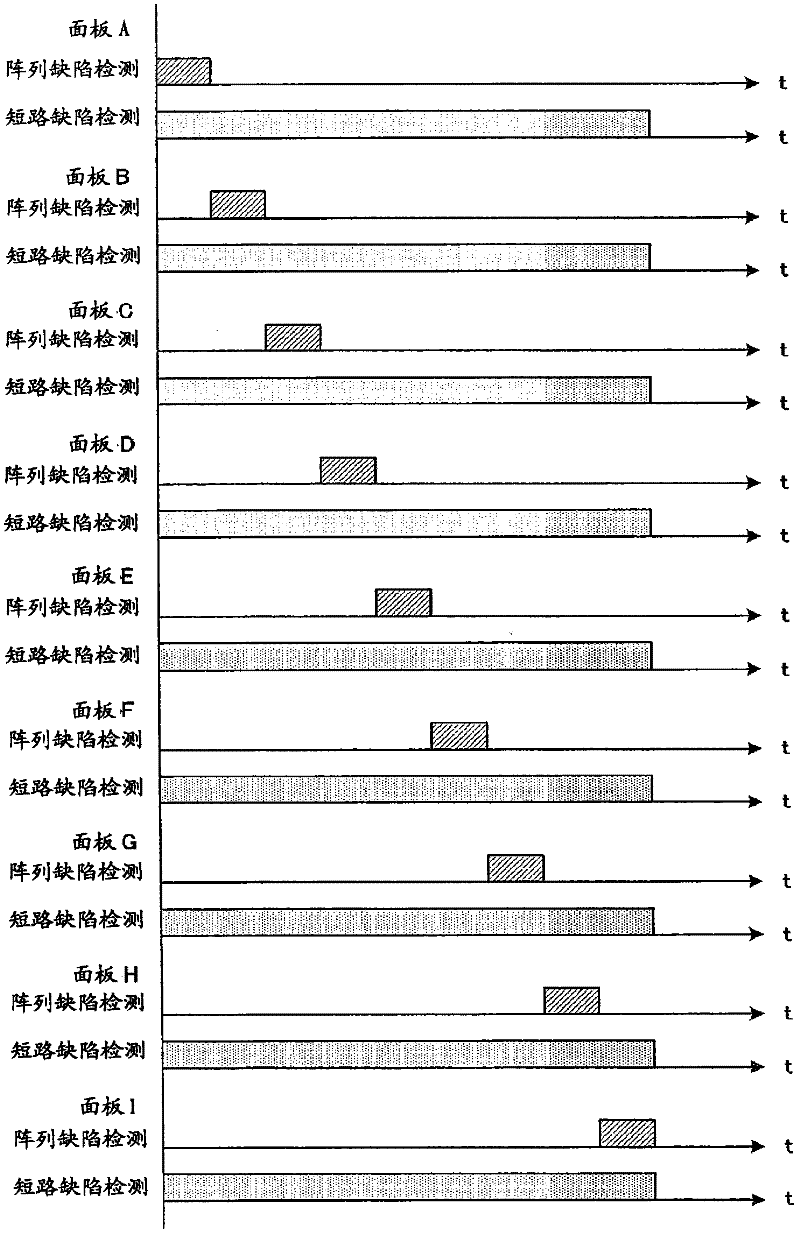

[0113] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram of the TFT substrate inspection apparatus of the present invention.

[0114] The TFT substrate inspection apparatus 1 detects array defects and short-circuit defects of a TFT substrate 20 mounted on a stage 11 installed in a vacuum chamber (not shown).

[0115] The composition for detecting array defects includes: an electron beam source 6, which irradiates electron beams onto the TFT substrate 20; a platform 11, which moves the TFT substrate 20 along the x and y directions; a scanning control part 5, which controls the electron beam source 6 and The platform 11 controls the electron beam to scan on the TFT substrate 20; the secondary electron detection part 7 detects the secondary electrons released from the TFT substrate 20; the secondary electron frame image acquisition part 8 detects the secondary electrons according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com