Electric heating system, in particular for a hybrid vehicle or electric vehicle

A technology for hybrid electric vehicles and electric vehicles, which is applied in the direction of power supply using engine-driven traction, ohmic resistance heating, and electric heating circuits, and can solve problems such as current load reduction and increased design complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

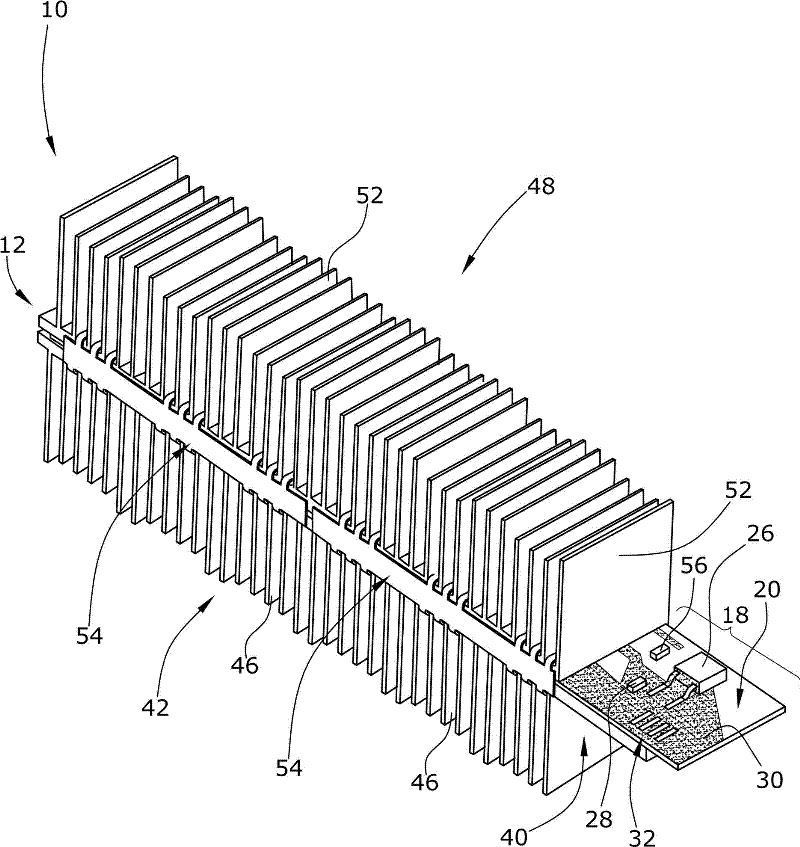

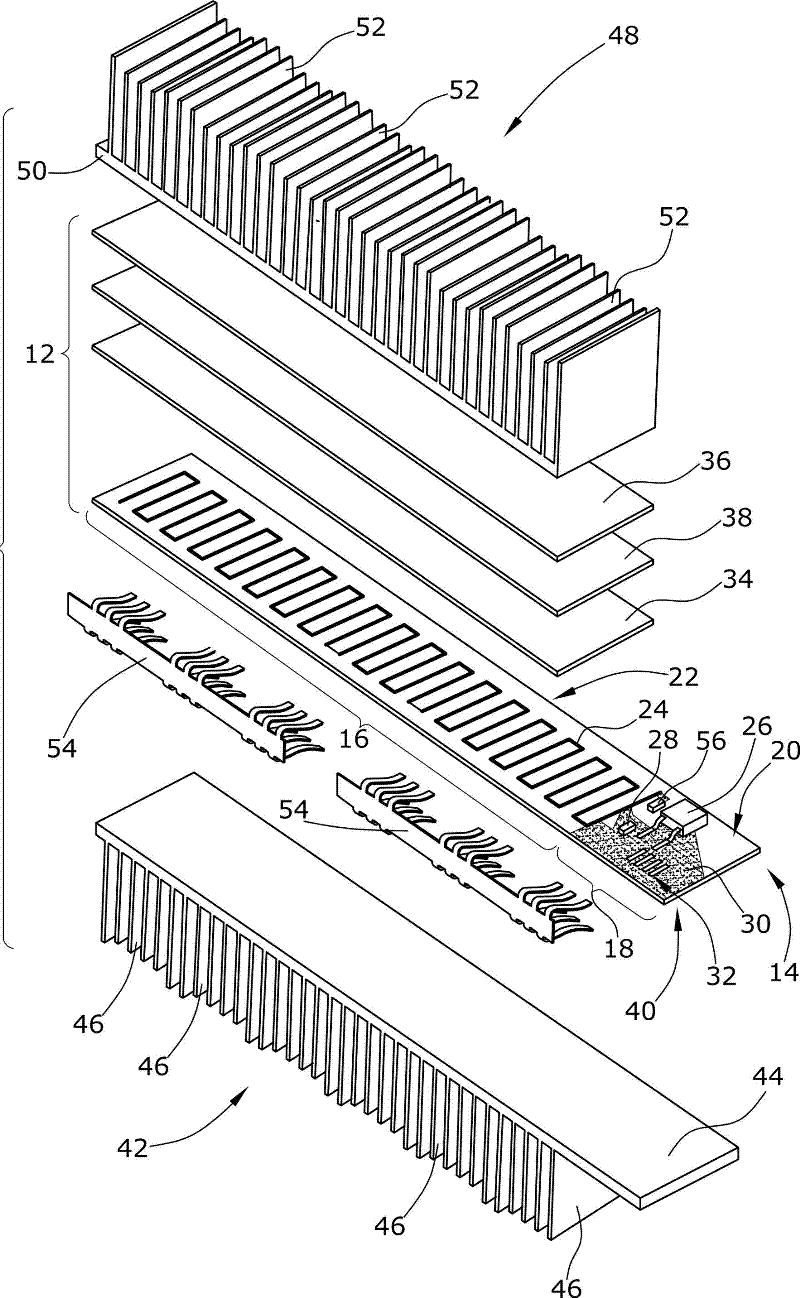

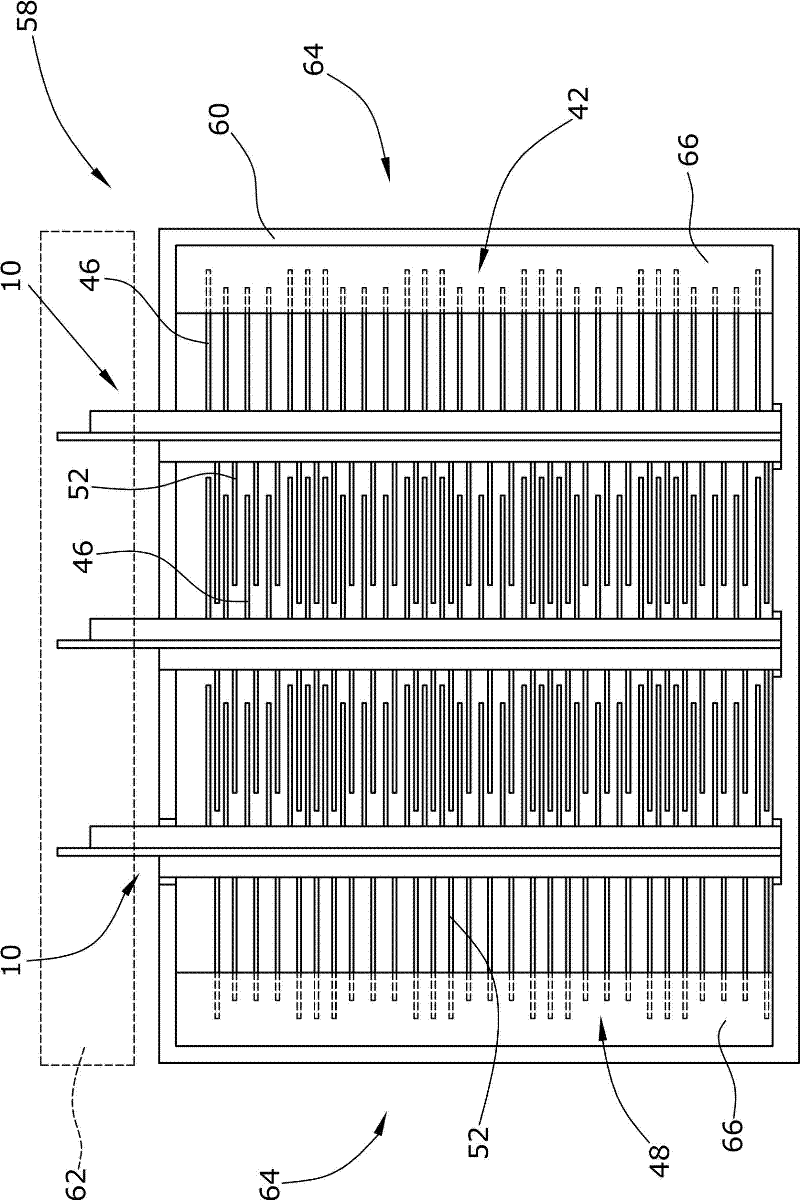

[0028] figure 1 A perspective view of a heating module 10 is shown, the configuration of which is shown in figure 2 Perspective and exploded view of the structure. The heating module 10 is designed for use in high-voltage on-board electrical systems of up to 400V in vehicles, especially hybrid or electric vehicles. The heating module 10 comprises a central electric heating element 12 having a layer composition as described below. Heating element 12 includes a ceramic substrate 14 that is divided into a heating zone 16 and a control zone 18 . Both districts 16 and 18 are located in figure 2 The upper side 20 of the ceramic substrate 14 . In the heating zone 16 , a resistive heating element 22 is provided on the ceramic substrate 14 in the form of a resistive heating conductor 24 , the current of which is controlled by a transistor 26 , in particular by means of a solder paste printing method. Transistors 26 and other electrical components 28 are located within control re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com