Novel cultivator

A cultivator and a new type of technology, applied in the directions of planting methods, chassis of agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of troublesome transportation, large area and large size of the cultivator, and achieve automatic control and land occupation. The effect of reducing the area and solving the work blind spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

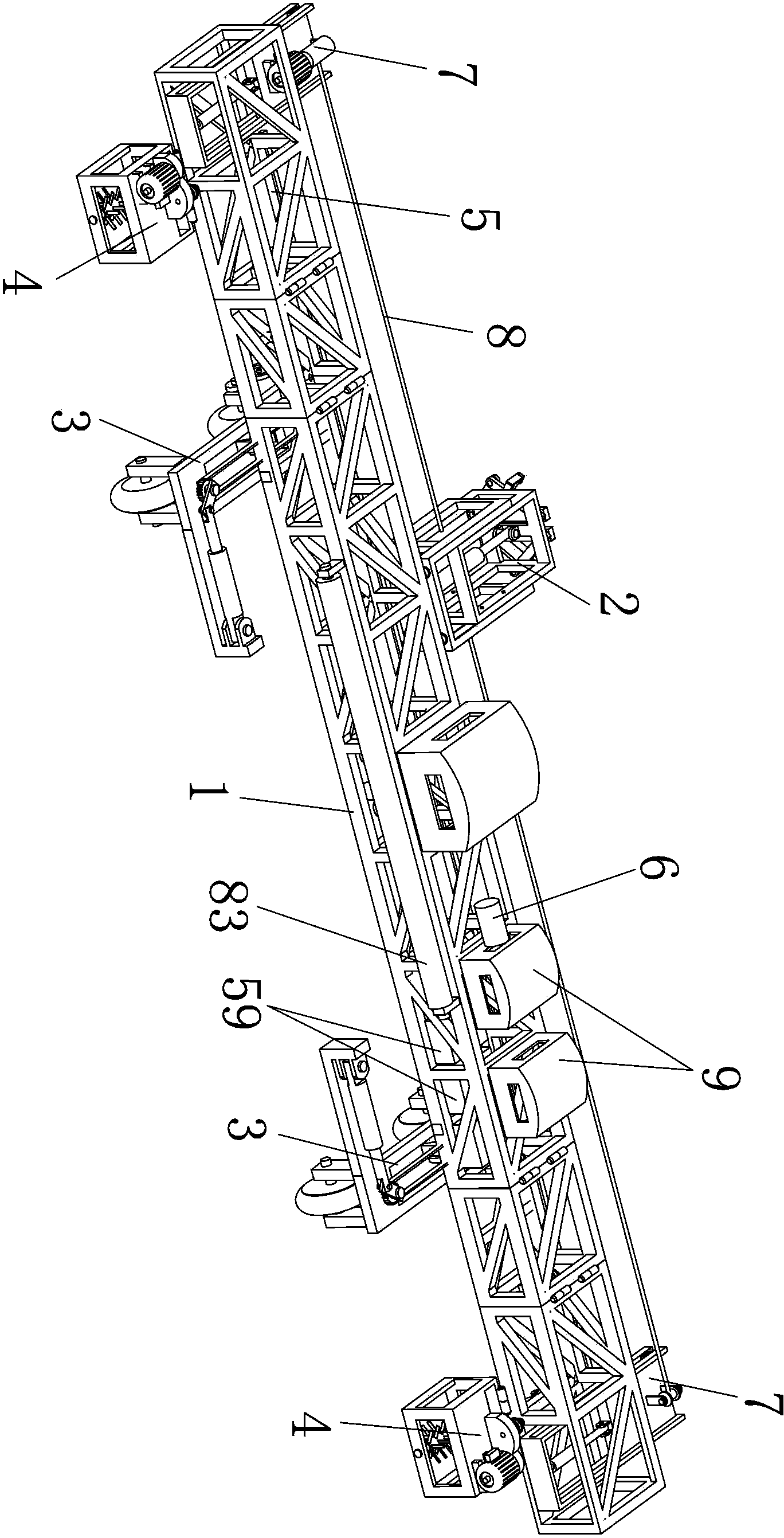

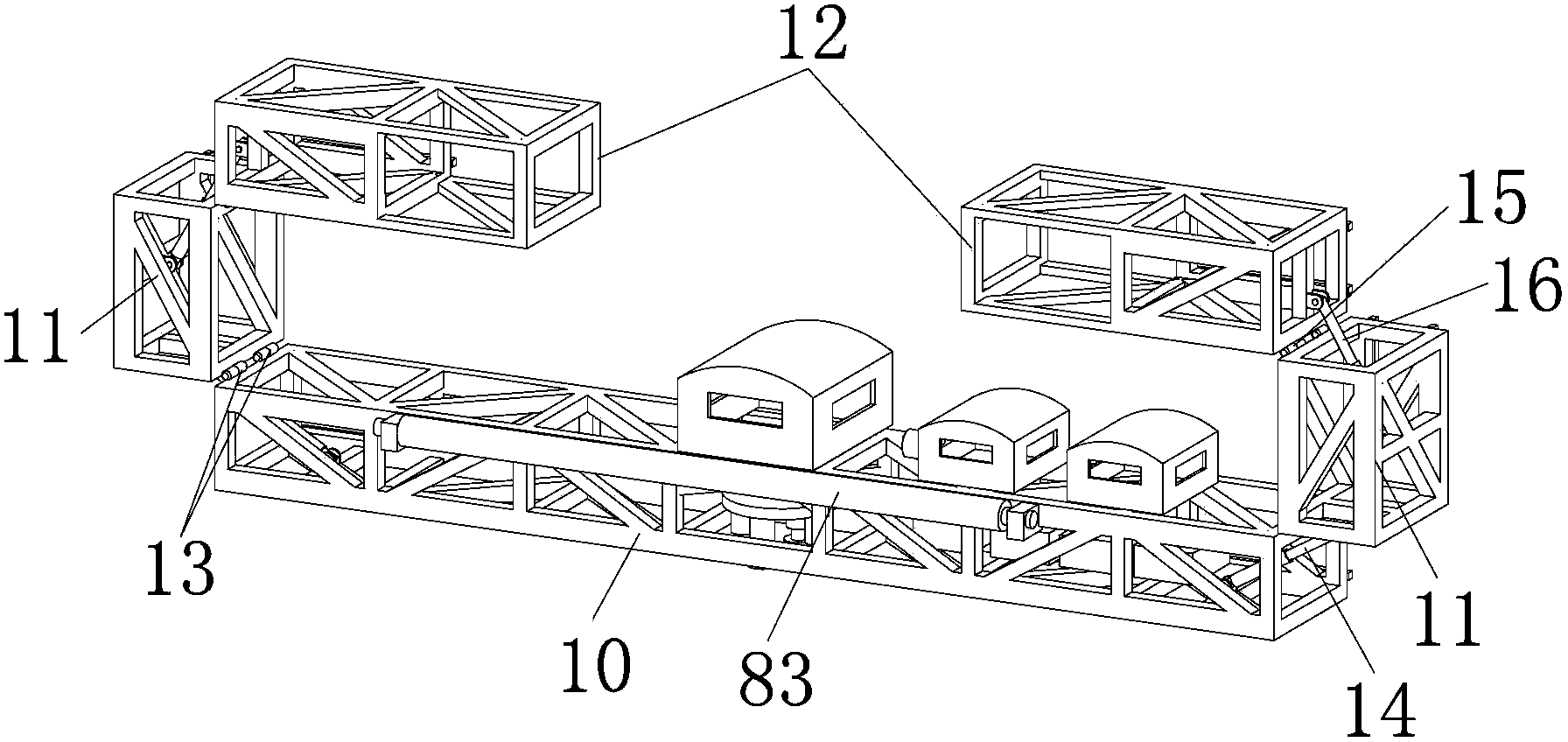

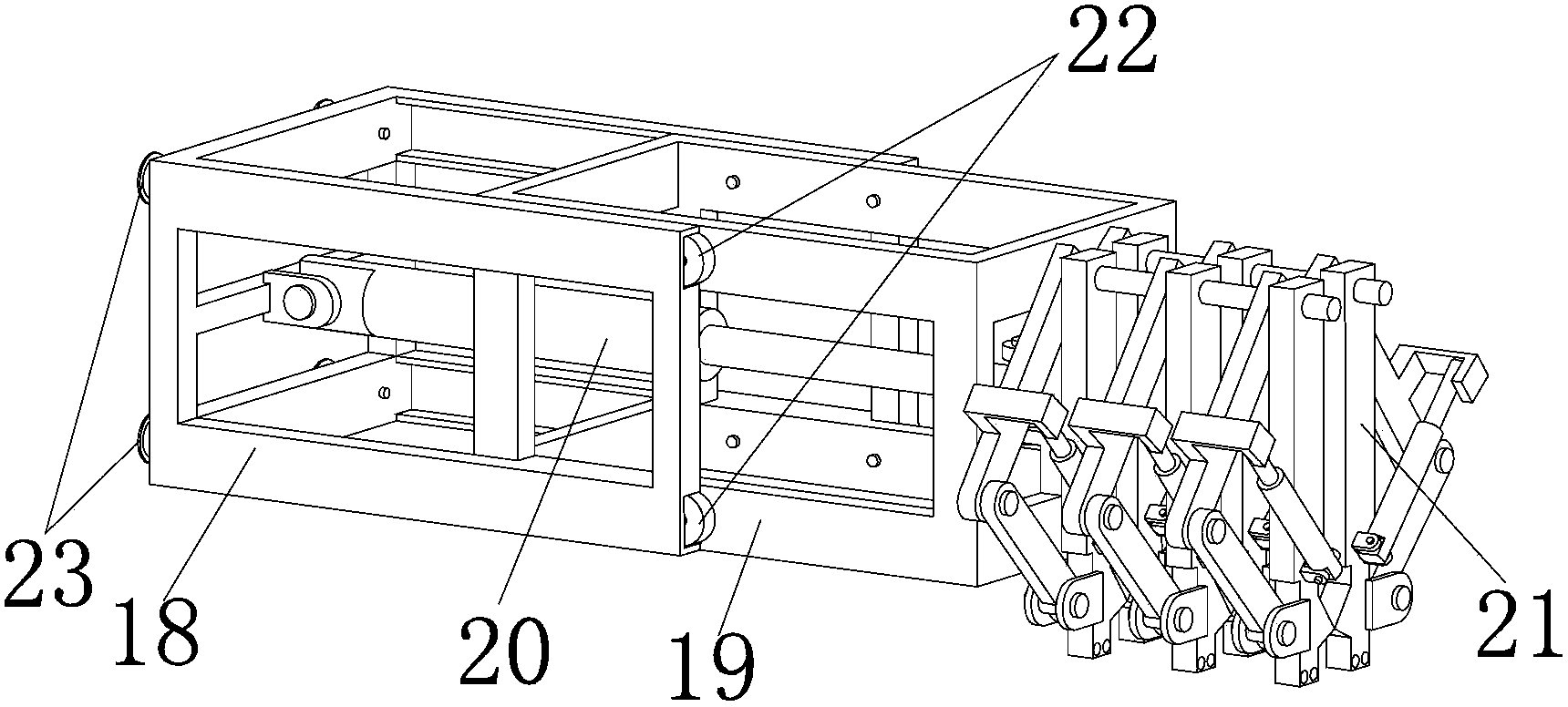

[0043] Embodiments of the present invention: a novel cultivator, such as figure 1 Shown, comprise folding frame 1, multifunctional tillage device 2, walking device 3, ditching device 4 and power supply system 59, on a side of foldable frame 1 walking track 5, multifunctional tillage device 2 is located at walking On the track 5, the two ends of the foldable frame 1 are provided with a telescopic traction device 7, the telescopic traction device 7 is connected with the multifunctional tillage device 2 through a wire rope 8, and the bottom of the foldable frame 1 is provided with no less than 2 The two ends of the foldable frame 1 are respectively provided with a ditching device 4, the ditching device 4 is arranged on the opposite side of the telescopic traction device 7, and the top of the foldable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com