Drying device for dried fruit processing production line

A drying device and assembly line technology, applied in food processing, application, food science and other directions, can solve the problems of wasting water, damage to the shape of dried fruits, and swelling of dried fruits due to water absorption, and achieve the effect of improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

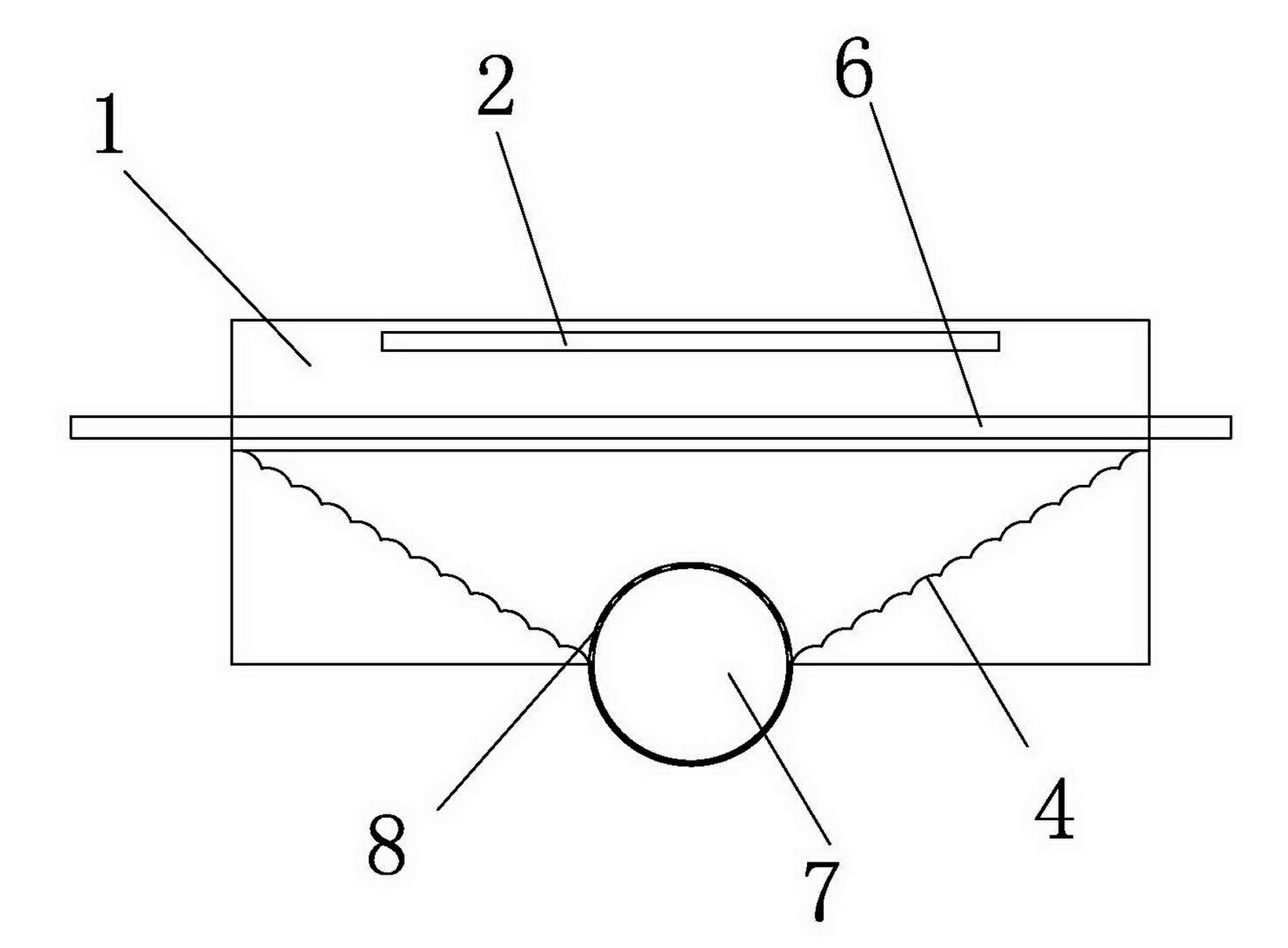

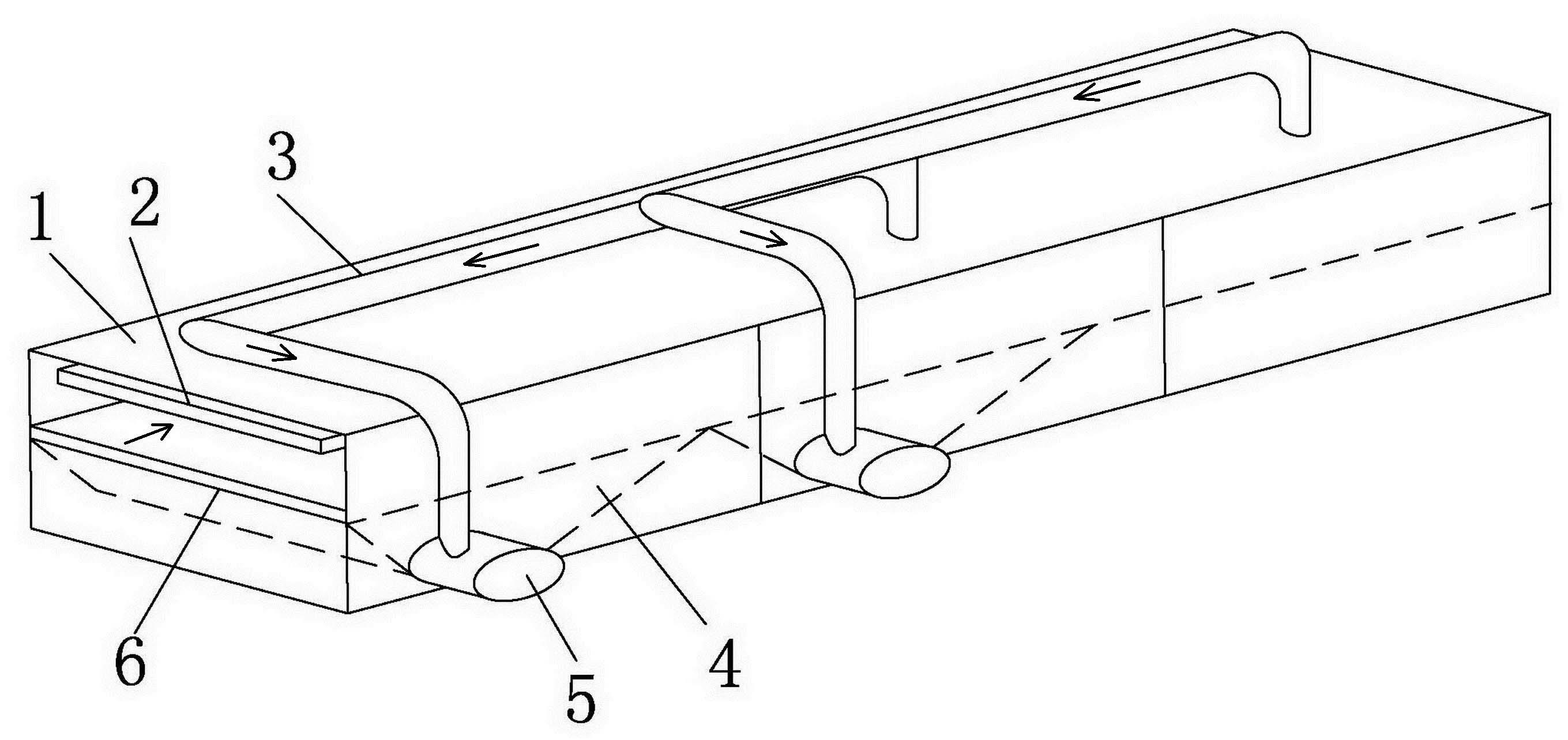

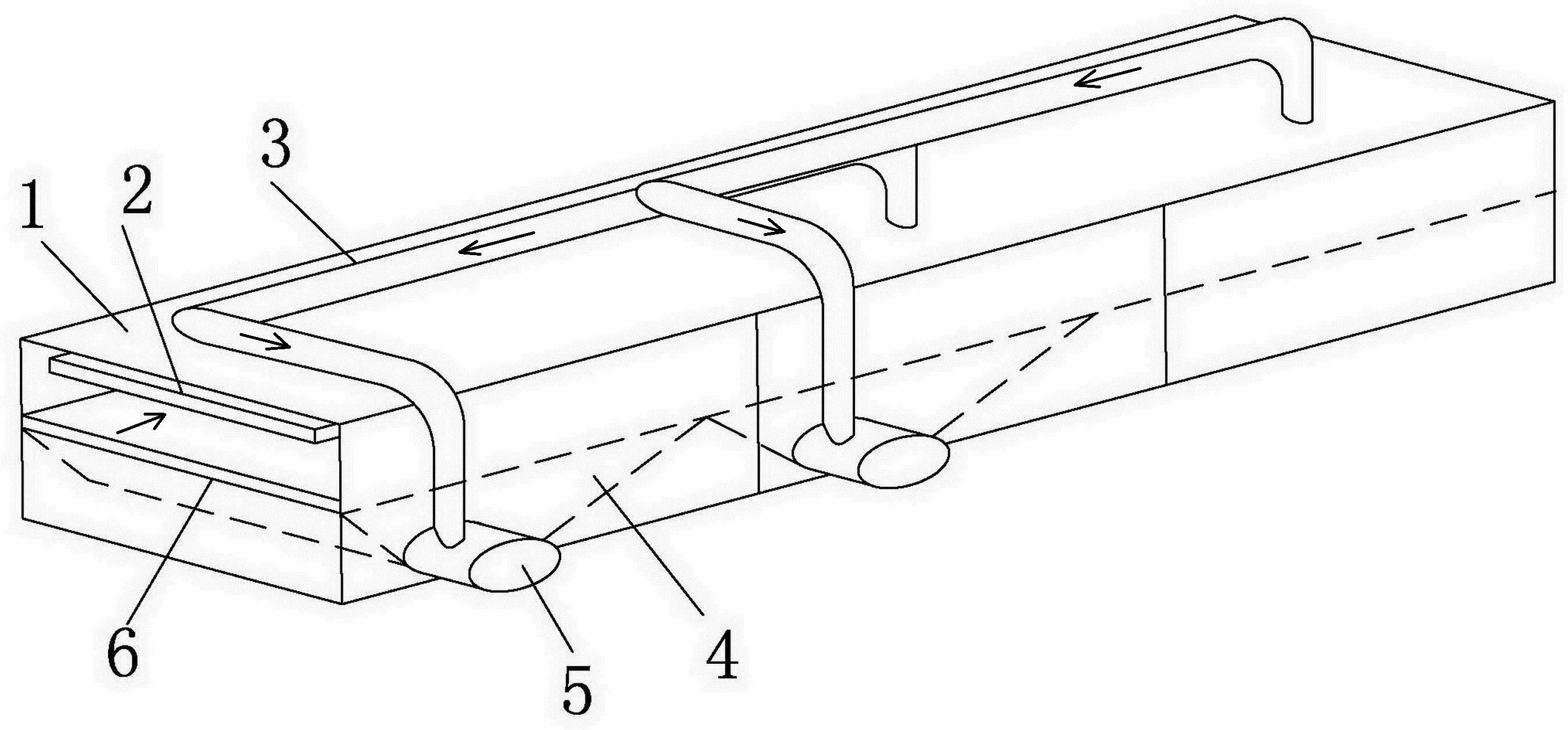

[0009] A drying device for a dried fruit processing line, such as figure 1 , figure 2 As shown, it includes a box body 1 with a built-in horizontal conveyor belt 6, an electric heating plate 2 or an electric heating wire is arranged on the top surface in the box body 1, and the top surface of the dried fruit is dried by the electric heating plate. Several conical air buckets 4 are installed side by side in the box body 1 below the horizontal conveyor belt 6, and a blower 5 is installed on the side wall of each conical air bucket 4. Along the running direction of the conveyor belt, the front The entrance of a blower suction duct 3 is at least installed on the casing top surface above the adjacent next conical wind bucket. For example: the inlet of the suction pipe of the first blower is installed on the top surface of the box above the third conical air bucket, and the inlet of the suction pipe of the second blower is installed on the box above the fourth conical air bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com