Automatic torque protection device for thickener

An automatic protection and thickener technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve the problems of inconvenient maintenance and replacement, unstable work, etc., and achieve the effect of beautiful appearance, stable and reliable work, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

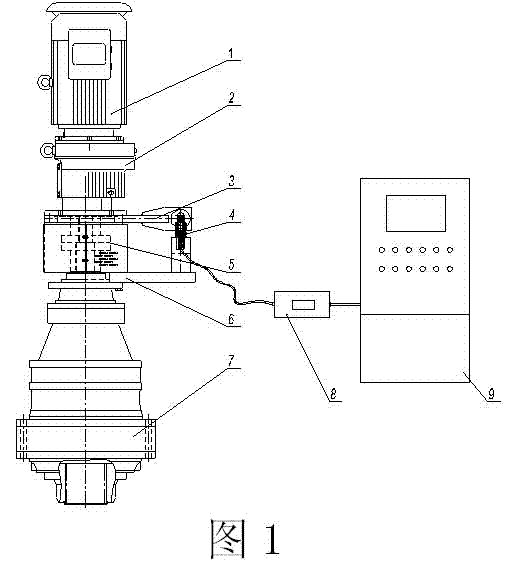

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, a thickener torque automatic protection device includes a motor 1, a reducer, an electronic torque sensor 4, a shaft coupling 5, a signal transmitter 8 and a PLC electronic control system 9, and the reducer includes a The first-stage reducer 2 and the second-stage reducer 7, the first-stage reducer 2 and the second-stage reducer 7 are planetary gear reducers, the motor 1 is connected with the first-stage reducer 2, and the first-stage The reducer 2 and the secondary reducer 7 are connected through a coupling 5, and the bodies of the primary reducer 2 and the secondary reducer 7 are respectively provided with upper and lower fixing seats 3, 6, and the upper , The lower fixing bases 3 and 6 are connected with the electronic torque sensor 4, and the electronic torque sensor 4, the signal transmitter 8 and the PLC electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com