Parallel flow wet dust-collecting device and operational method thereof

A technology of wet dust removal and operation method, which is applied in the field of dust-laden gas purification and gas purification, can solve the problems of large system resistance, high energy consumption, large power consumption, etc., and achieves low power consumption, water conservation, and tower diameter. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

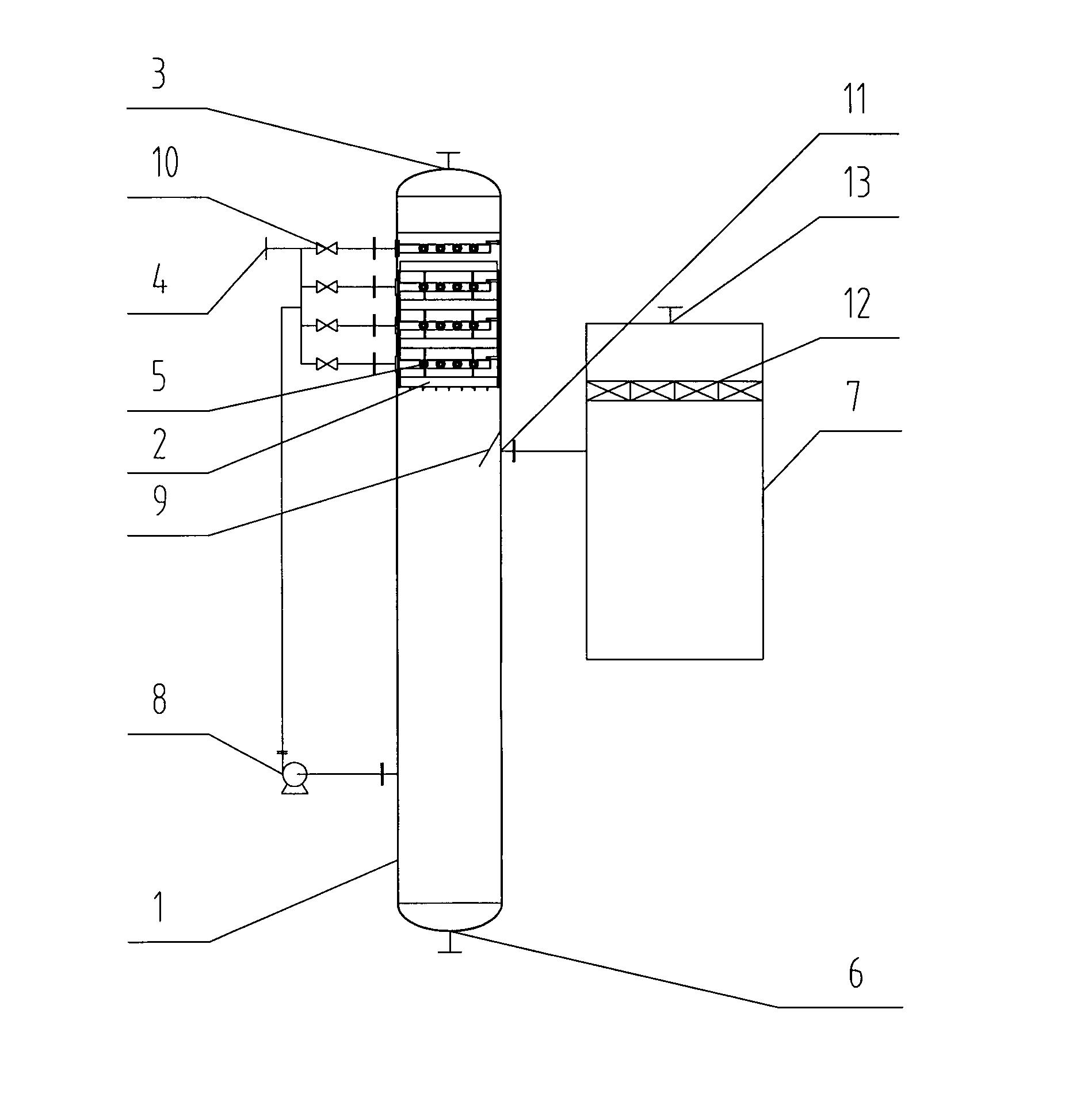

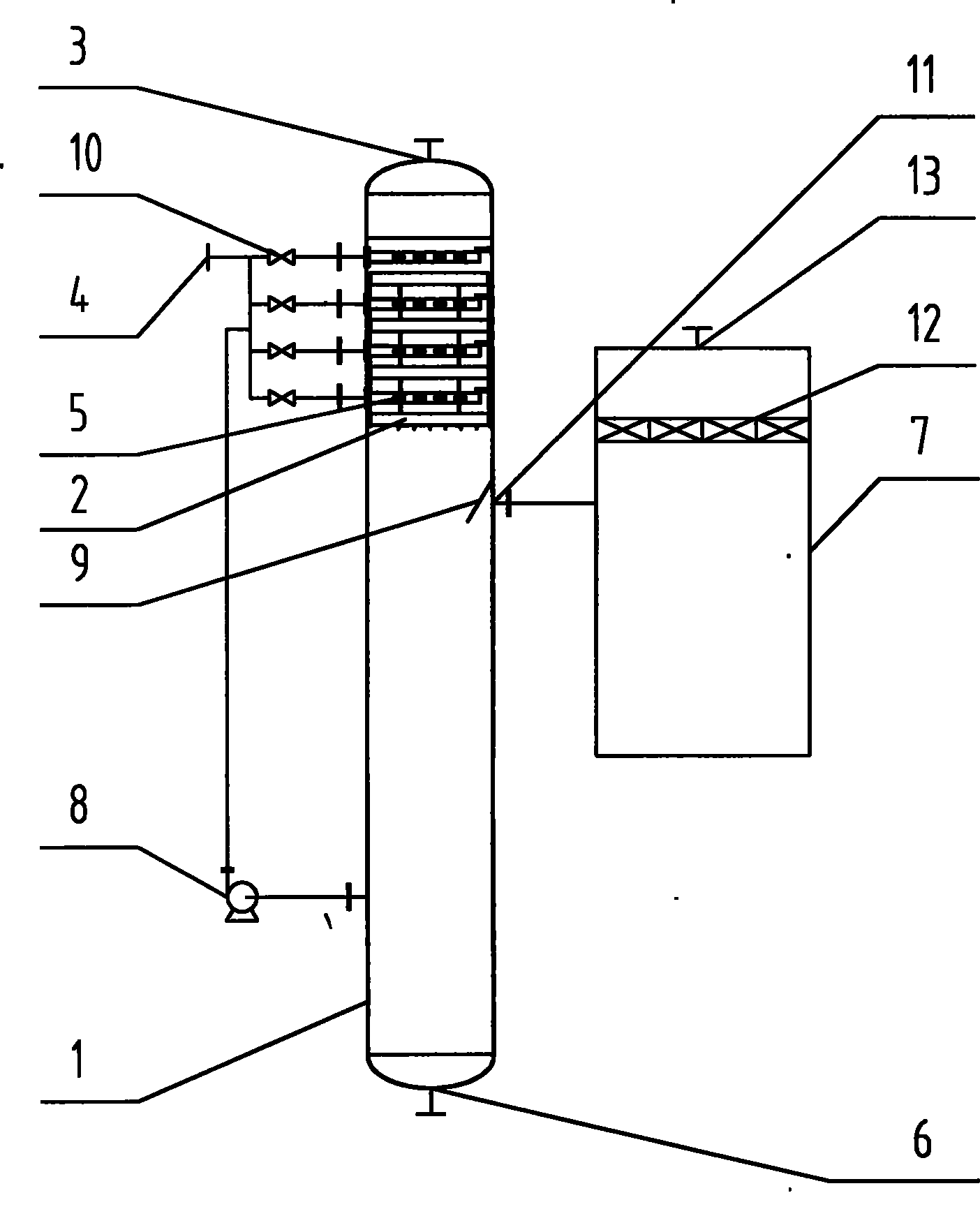

[0014] The parallel flow wet dust removal device of the present invention will be described in detail below with reference to the accompanying drawings.

[0015] A dusty gas flow rate of 60000Nm 3 / h, the gas contains elemental sulfur dust, and the elemental sulfur content is 80mg / Nm 3 , particle size 3.2μm, operating pressure 0.55 ~ 0.6MPa. The gas containing elemental sulfur enters the tower body 1 of the co-current wet dedusting device through the inlet pipe 3 on the upper part of the dedusting device. The diameter of the tower body 1 of the co-current wet dedusting device used is 1500mm, and four cyclone mixers 2 are set. The blades of the first and third cyclone mixers are installed clockwise, the blades of the second and fourth cyclone mixers are installed counterclockwise, and the installation distance is 600mm. A pipe-type liquid distributor 5 is installed on the upper part of each cyclone mixer, and a circulation pump 8 and a regulating valve 10 are installed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com