Processing device and processing method for spherical pit of piston of automobile air conditioner

A technology for processing devices and automotive air conditioners, applied in positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of low geometric tolerance accuracy, low processing efficiency, and unreliable clamping, so as to ensure processing quality and shape. Position tolerance accuracy, improve surface quality and geometric tolerance, precise positioning and clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

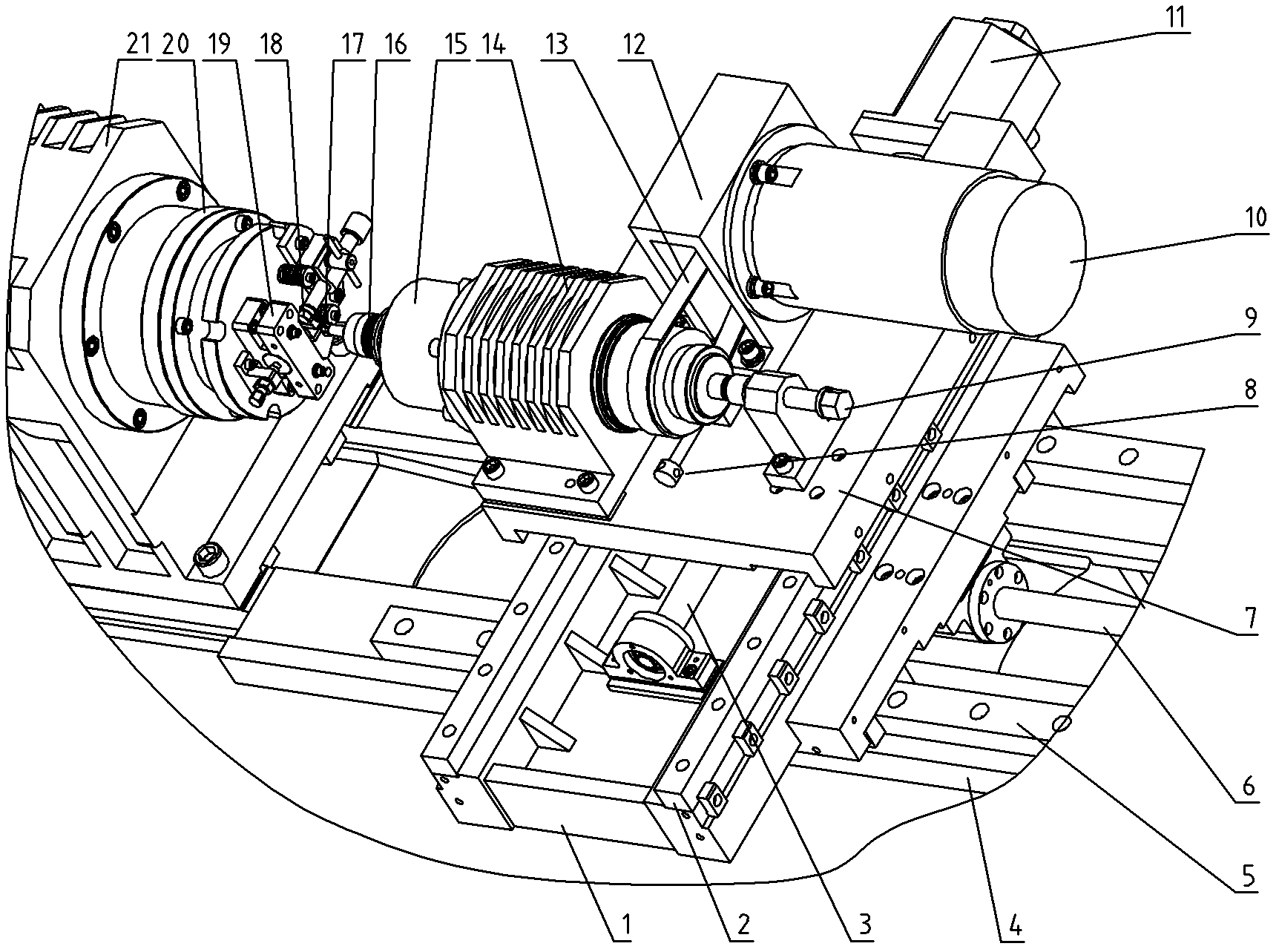

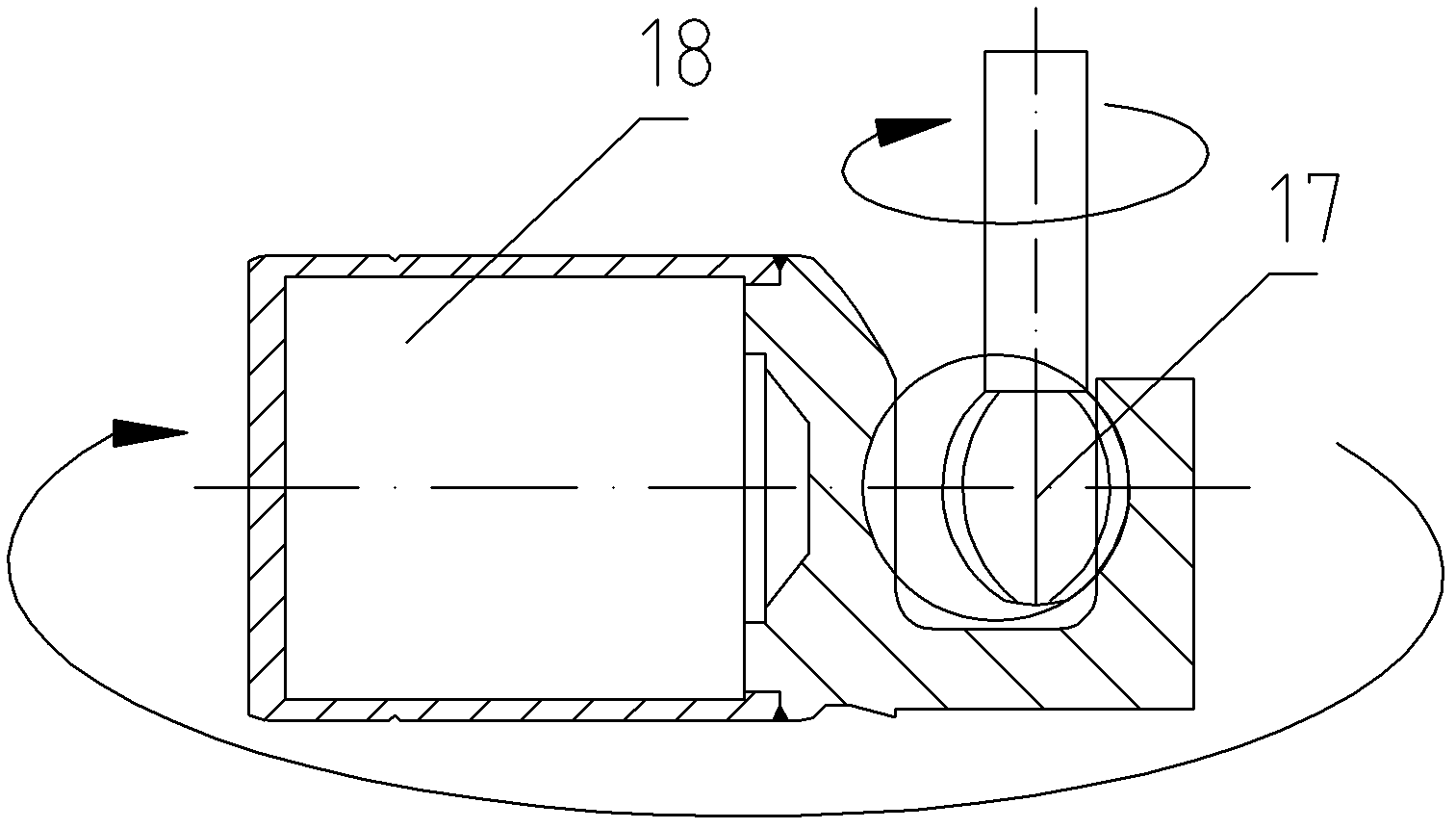

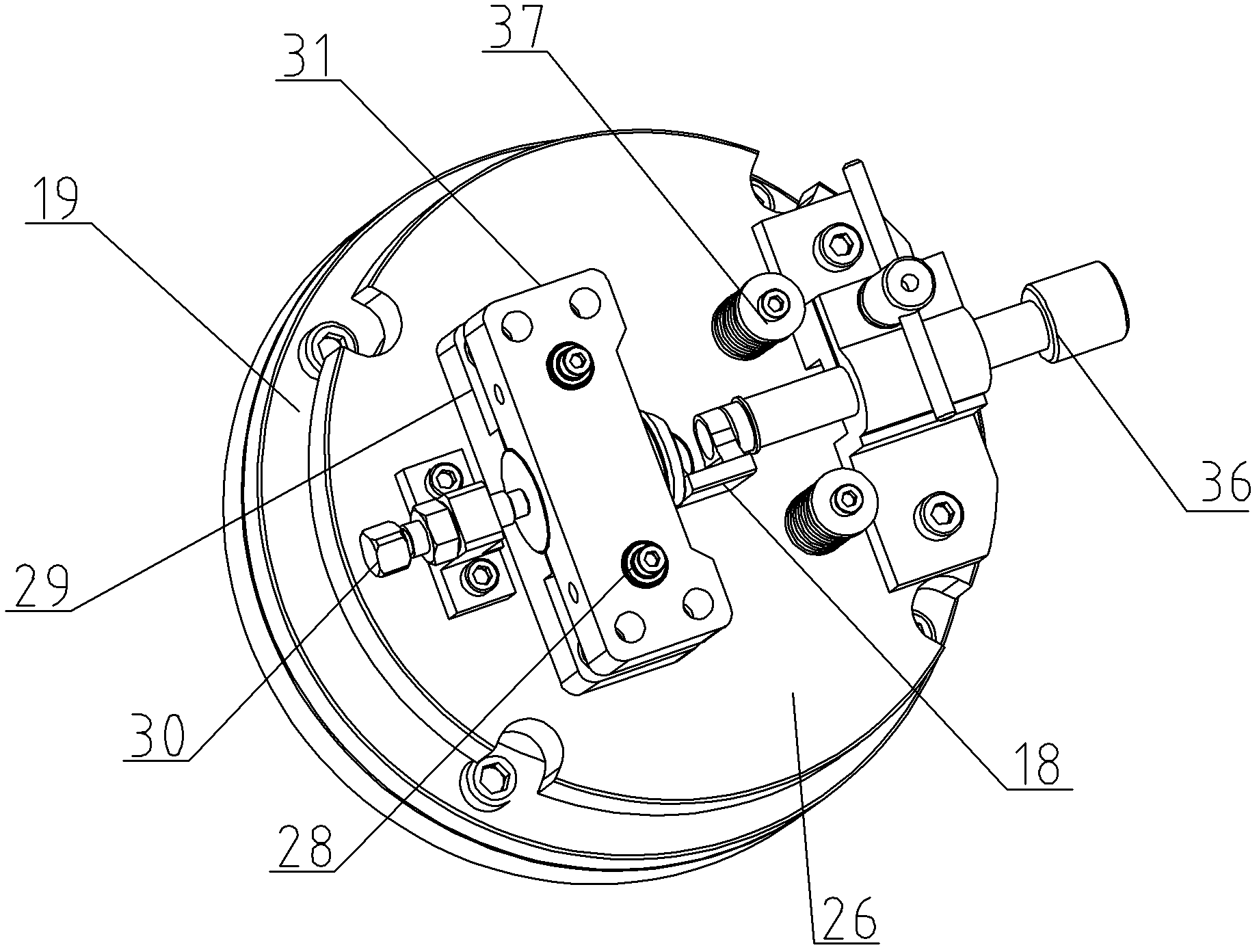

[0030] in figure 1 In the illustrated embodiment, an automobile air-conditioning piston ball pit processing device includes a milling machine frame on which a headstock 21 is provided. The front end of the headstock 21 is provided with a machine tool spindle 20, and the front end of the machine tool spindle 20 is provided with a workpiece The clamping tool 19, the workpiece clamping tool 19 includes a tool connecting plate 25, a clamping body 26, a radial clamping device and an axial positioning device. The clamping body 26 is connected to the tooling connection plate 25, and the radial clamping device is arranged on the clamping body. On the end face of 26, the axial positioning device is perpendicular to the radial clamping device and is arranged on the end face of the clamping body 26. The workpiece clamping fixture 19 is rotated together with the spindle 21 of the machine tool. The machine bed 4 is provided with a tool transverse feed device. And the tool longitudinal feed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com